Combined strains for highly producing baccatin III and method for producing baccatin III

A strain and high-yield technology, applied in the direction of fungi, fermentation, etc., can solve the problem of paclitaxel being inseparable, and achieve the effects of reducing production costs, weakening dependence, and reducing environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example 1 no.79 combined with Z58 to produce baccatin III

[0039] The following are the specific steps for the mixed culture of no.79 and Z58 strains to extract baccatin III:

[0040] (1) Preparation of medium:

[0041] 1) PDA medium: 200g potato, 20g sucrose, 20g agar, 1000mL water, natural pH.

[0042] 2) Fermentation medium: potato 200g, bran 10g, yeast extract 1g / L, sucrose 20g, sodium benzoate 250mg / L, magnesium sulfate 0.4g / L, potassium dihydrogen phosphate 2g / L, water 1000mL, natural pH. Peel and cut the potatoes into strips, boil in water for 30 minutes, filter through 4 layers of gauze; boil the bran in water for 30 minutes, filter through 4 layers of gauze.

[0043] (2) Bacteria pre-cultivation: Pick the endophytic fungus no.79 producing baccatin Ⅲ and the endophytic fungus Z58 producing paclitaxel and inoculate them in 60 mL PDA medium respectively, and culture them at 25°C and 100 rpm / min for 1 day to form seeds fermentation broth.

[0044] (3) Bacteria...

Embodiment 2

[0049] Embodiment 2 no.79 and Gliocladium sp. combine to produce Baccatin III

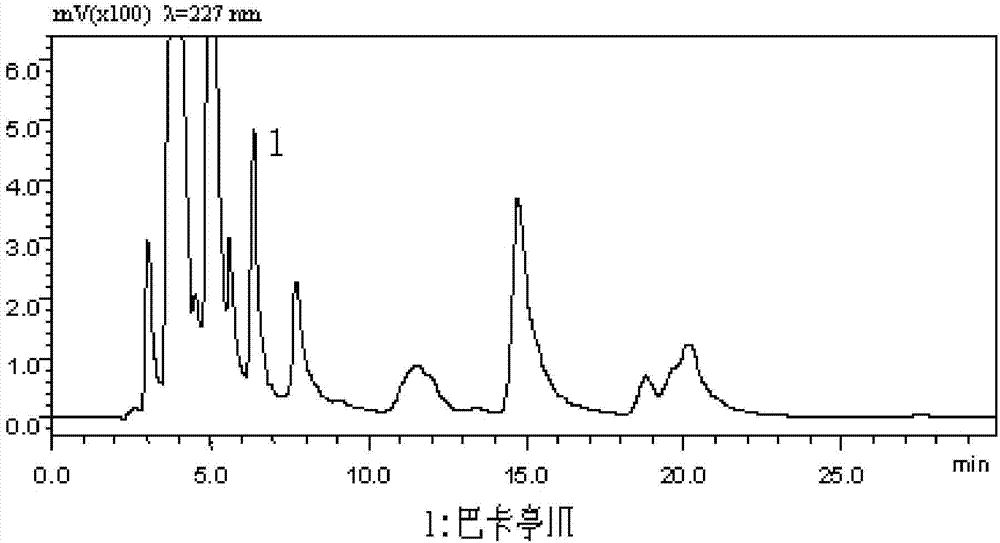

[0050] The embodiment is consistent with Example 1, the baccatin III-producing strain used is no.79, and the paclitaxel-producing strain is Gliocladium sp. Fermentation medium used: potato 200g, bran 5g, yeast extract 1g / L, sucrose 20g, magnesium sulfate 2g / L, sodium benzoate 250mg / L, zinc sulfate 0.05g / L, ammonium molybdate 0.15g / L, water 1000mL, natural pH. Fermentation conditions were unchanged, mixed fermentation and separate fermentation were carried out. Fermentation product carries out high performance liquid chromatography detection, and the content of mixed fermentation baccatin III is 9.36mg / L (see figure 2 ), the yield of baccatin Ⅲ after mixed fermentation was 42.7 times higher than that of single culture no.79.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com