Manufacturing method for silane type product

A manufacturing method and silane technology, applied in the direction of silicon hydride, etc., to achieve the effect of eliminating the risk of chlorine and halogen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

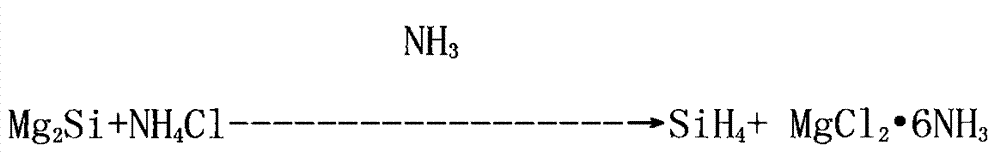

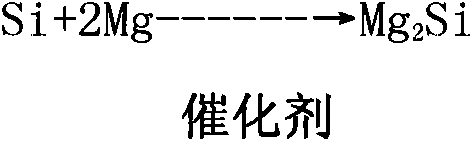

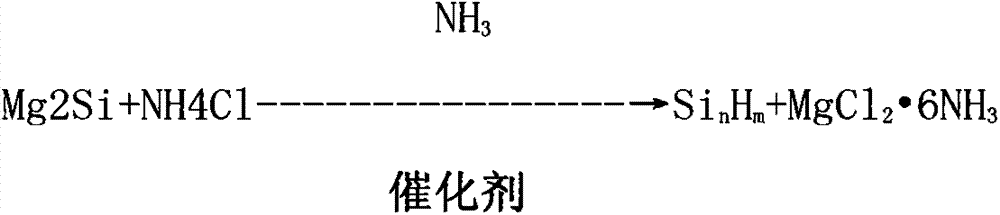

Method used

Image

Examples

Embodiment 1

[0052] Carry out steps A, B, C, D, E according to the above method. Wherein, the catalyst used in step B is a mixture of zinc salt and rhodium salt; the separation in step C is to sequentially separate silyl propane, silyl ethane and silyl methane by cooling down. First, the silane mixed gas was cooled to -120°C to separate silylpropane; then the temperature was lowered to -170°C to separate silane ethane; and then the temperature was lowered to -240°C to separate silylmethane. Thus, silamethane, silaethane, and silapropane are all present in the liquid phase.

[0053] After all kinds of silane products are produced, they need to undergo precision purification operations to meet the high-precision purity of high-tech electronic products. The gas phase is formed, and then the temperature is lowered to obtain silicon methane at a temperature of -220°C. Therefore, impurities that are not at this temperature will be removed to improve the purity. In the same way, the silane is h...

Embodiment 2

[0055] Repeat Example 1, the difference is that the catalyst used in step B is zinc salt; in step C, the silane-based mixed gas is cooled to -60 ° C, and silyl propane is separated; Then the temperature was lowered to -170°C, and the silylmethane was separated. In the purification operation, the silamethane is further cooled to -180°C, the silane ethane is further cooled to -130°C, and the silapropane is further cooled to -70°C.

Embodiment 3

[0057] Repeat Example 1, the difference is that the catalyst used in step B is platinum salt; in step C, the silane-based mixed gas is cooled to -90°C to separate out silapropane; and then cooled to -145°C to separate out silane ethane: Then the temperature was lowered to -205°C, and the silylmethane was separated. In the purification operation, the silamethane is cooled to -200°C again, the silane ethane is further cooled to -145°C, and the silapropane is further cooled to -90°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com