Method for eliminating central looseness of casting blank and improving density of casting blank

A technology with loose and dense center, applied in the field of metallurgy, can solve the problems of limited reduction, increased maintenance, production cost, etc., and achieve the effect of reducing the problem of looseness, increasing the density, and improving the density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

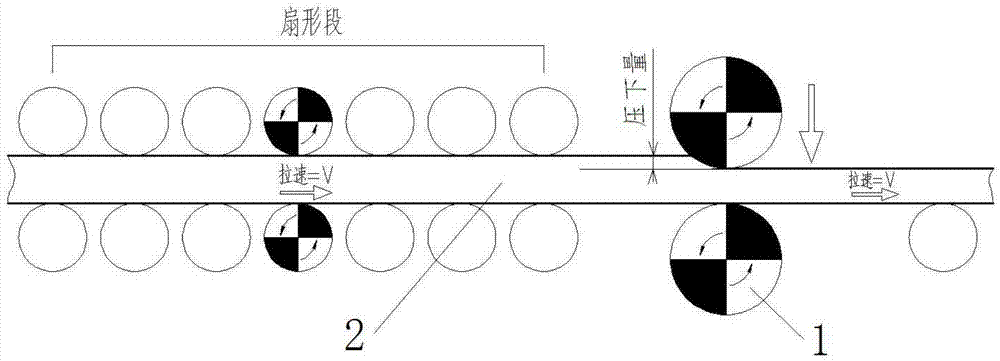

[0023] For a certain conventional steel type, a straight arc continuous casting machine is used to produce a slab with a section of 300mm×2300mm. A set of pressing rollers is set behind the horizontal sector to control the surface temperature of the slab coming out of the exit of the horizontal sector at 800-850 In the range of ℃, the roll diameter of the pressing roll is 800mm, and the rolling amount is 10mm.

Embodiment 2

[0025] For a certain conventional steel type, a straight arc continuous casting machine is used to produce slabs with a section of 150mm×1900mm. Two sets of pressing rollers are arranged behind the horizontal sector to control the surface temperature of the slab coming out of the exit of the horizontal sector at 800-850 In the range of ℃, the roll diameter of the pressing roll is 300mm, and the rolling amount is 5mm.

Embodiment 3

[0027] For a certain conventional steel type, a straight arc continuous casting machine is used to produce a slab with a section of 450mm×2100mm. Two sets of pressing rollers are set behind the horizontal sector to control the surface temperature of the slab coming out of the exit of the horizontal sector at 820-900 In the range of ℃, the roll diameter of the pressing roll is 700mm, and the rolling amount is 25mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com