A kind of microchannel reactor and the method using it to produce magnetic titanium silicon molecular sieve

A technology of microchannel reactor and titanium-silicon molecular sieve, which is applied in chemical instruments and methods, molecular sieves and alkali exchange compounds, crystalline aluminosilicate zeolites, etc., can solve the problems of high frequency of starting and stopping, insufficient mixing, reaction rate and diffusion Slow speed and other problems, to achieve the effect of enhancing mass transfer, increasing production rate, and improving catalyst performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

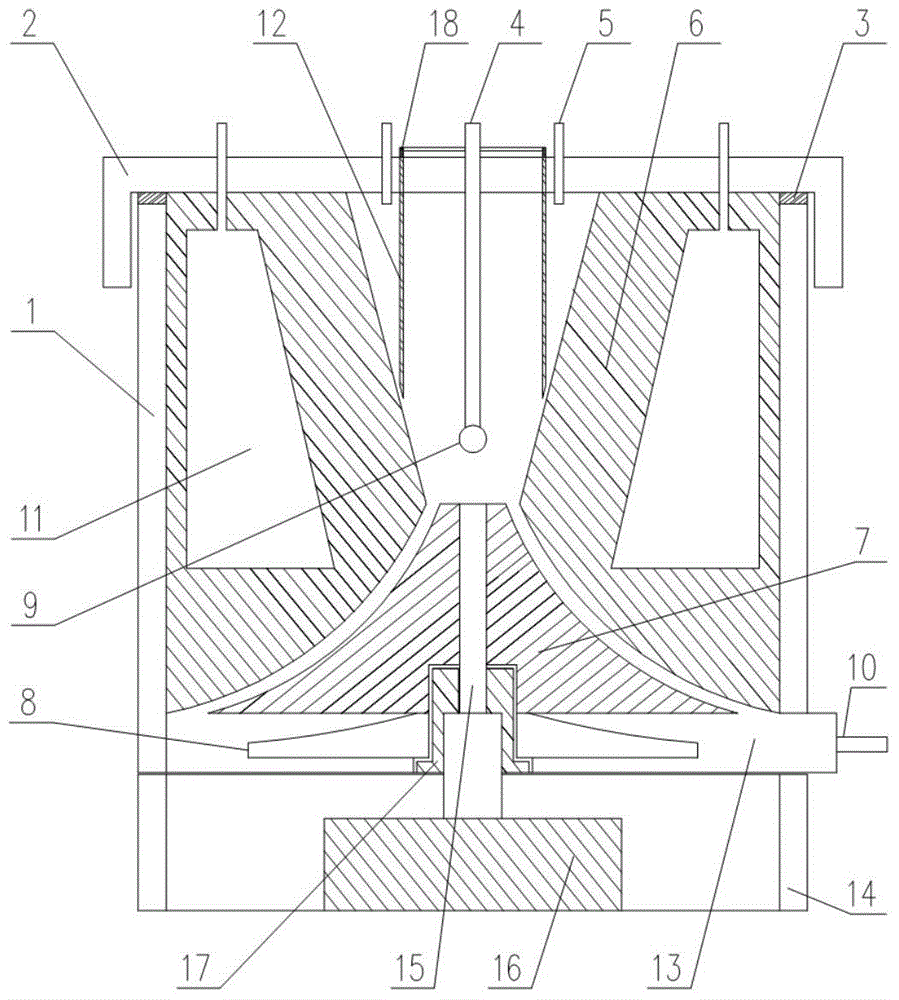

[0045] The inner cavity of the static grinding disc 6 has a two-stage variable diameter, and the upper half of the static grinding disc 6 has a gradually decreasing diameter from top to bottom, which is the upper variable diameter; the lower half of the static grinding disc 6 has a gradually decreasing diameter from top to bottom. Incrementally, it is the lower variable diameter; and the upper variable diameter of the static grinding disc 6 inner cavity and the outer wall of the falling film tube 12 form the first-stage falling film microchannel, and the size of the falling film microchannel outlet is 400 microns. The variable diameter of the lower part of the cavity and the outer wall surface of the movable grinding disc 7 form the second-stage reaction microchannel, and the thickness of the reaction microchannel is 700 microns; The shape of the lower diameter-reducing wall is corresponding; the taper of the upper diameter-reduction of the inner chamber of the static grinding ...

Embodiment 2

[0053]The inner cavity of the static grinding disc 6 has a two-stage variable diameter, and the upper half of the static grinding disc 6 has a gradually decreasing diameter from top to bottom, which is the upper variable diameter; the lower half of the static grinding disc 6 has a gradually decreasing diameter from top to bottom. Incrementally, it is the lower variable diameter; and the upper variable diameter of the static grinding disc 6 inner cavity and the outer wall of the falling film tube 12 form the first-stage falling film microchannel, and the size of the falling film microchannel outlet is 500 microns, and the static grinding disc 6 The variable diameter of the lower part of the cavity and the outer wall surface of the movable grinding disc 7 form the second-stage reaction microchannel, and the thickness of the reaction microchannel is 600 microns; The shape of the variable diameter wall is corresponding; the taper of the upper variable diameter of the inner cavity o...

Embodiment 3

[0060] Adopt the microchannel reactor of embodiment 1 to prepare the magnetically loaded titanium-silicon molecular sieve of aluminum modification, and its concrete steps are:

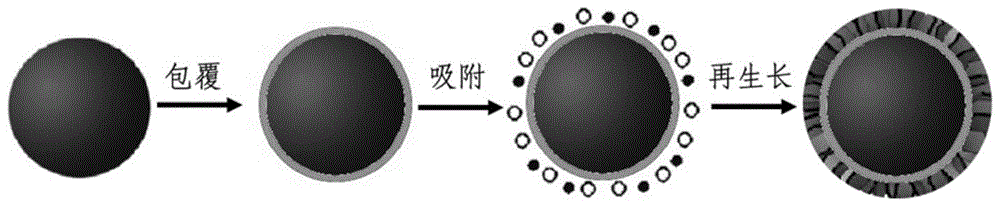

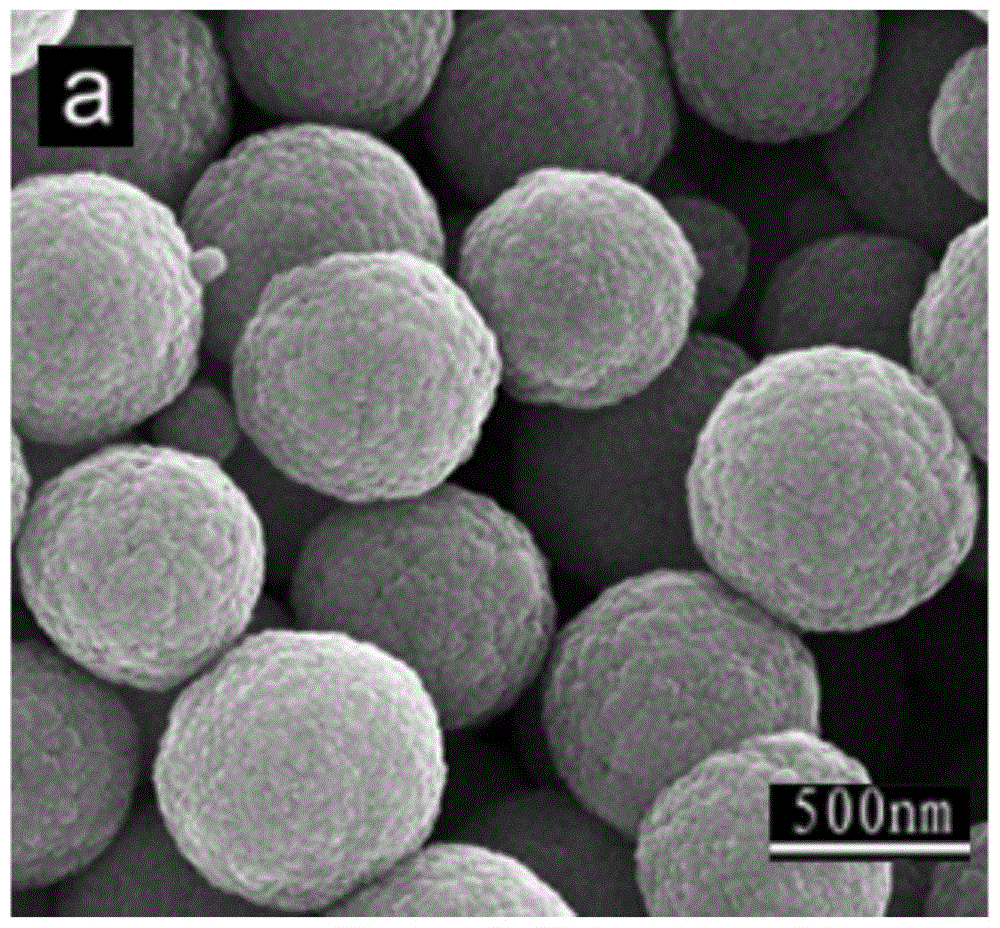

[0061] Make mixed solution A with ethyl orthosilicate, tetrapropyl orthotitanate and ethanol, and make mixed solution B with aluminum nitrate and tetrapropylammonium bromide; among them, ethyl orthosilicate, tetrapropyl orthotitanate , the molar ratio of aluminum nitrate and tetrapropylammonium bromide is 1:0.04:0.04:0.5, [SiO 2 ]=1.5mol / L; The prepared solution A and solution B are added to the microchannel reactor simultaneously, wherein, solution A flows through the No. 1 feed delivery pipe 4, and solution B flows through the No. 2 feed delivery pipe 5 , mixed instantaneously in the rapidly rotating reaction microchannel and quickly generated small seeds, and the mother liquor C formed was sent out of the reactor through the discharge conveying pipe 10 at the bottom of the grinding disc, wherein the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com