A kind of preparation method of alkyne selective hydrogenation catalyst

A technology for selective hydrogenation and catalysts, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc. Problems such as poor hydrogen selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

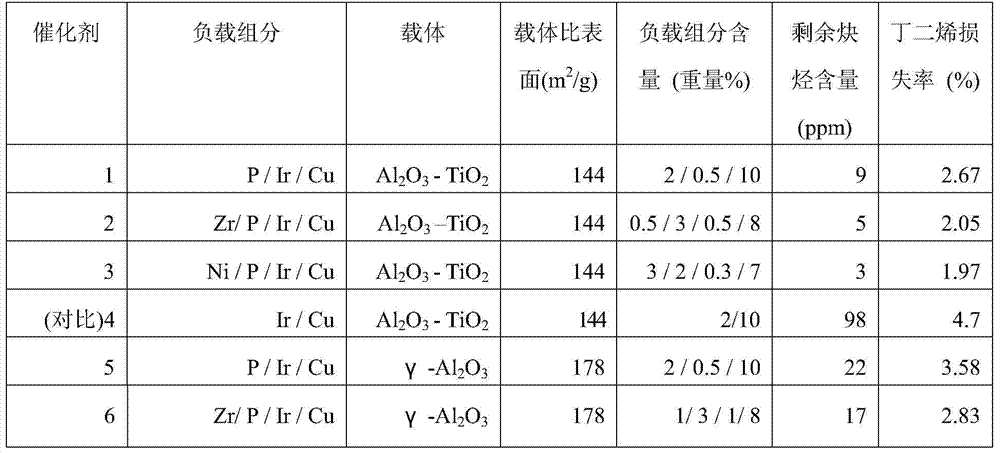

[0048] Embodiment 1—preparation of catalyst 1

[0049] Firstly, a titania-alumina composite oxide carrier was prepared according to the method in Example 1 of CN1184289C. Take the specific surface area as 160m 2 / g, 90g of clover-shaped alumina with a pore volume of 0.58mL / g and a most probable pore diameter of 130 angstroms, impregnated with 0.557g / mL dilute sulfuric acid solution of 63 ml of titanium sulfate, stirred for 15 minutes, and dried at 120°C for 8 hours Then, it was calcined at 900° C. for 4 hours to obtain a titanium oxide-alumina composite oxide (A-1). The obtained composite oxide had a titanium oxide content of 10% by weight and a specific surface area of 144m 2 / g, the pore volume is 0.56mL / g, and the most probable pore diameter is 125 angstroms.

[0050] Prepare 63mL of a mixed aqueous solution containing copper nitrate, ammonium phosphate, and iridium trichloride as the immersion solution. In the immersion solution, the amount of copper nitrate is 10% by...

Embodiment 2

[0051] Embodiment 2—preparation of catalyst 2

[0052] Prepare 63mL of a mixed aqueous solution containing copper nitrate, iridium trichloride, ammonium phosphate, and zirconium nitrate as the impregnating liquid. In the impregnating liquid, the amount of copper nitrate is 8% by weight calculated as copper element, and the amount of iridium trichloride is calculated as iridium element The amount of ammonium phosphate was 0.5% by weight, the amount of ammonium phosphate was 3% by weight as phosphorus element, and the amount of zirconium nitrate was 0.5% by weight as zirconium element. At room temperature, take 100g of titanium oxide-alumina composite oxide (A-1), impregnate it with the previously prepared impregnation solution, dry it at 120°C for 4 hours, then calcinate it at 500°C for 4 hours, take it out and cool it to room temperature . The catalyst prepared in this way is designated Catalyst 2.

Embodiment 3

[0053] Embodiment 3—preparation of catalyst 3

[0054] Prepare 63mL of a mixed aqueous solution containing copper nitrate, iridium trichloride, ammonium phosphate and nickel nitrate as the immersion solution, in the immersion solution, the amount of copper nitrate is 7% by weight calculated as copper element, and the amount of iridium trichloride is calculated as iridium element The amount of ammonium phosphate was 0.3% by weight, the amount of ammonium phosphate was 2% by weight as phosphorus element, and the amount of nickel nitrate was 3% by weight as nickel element. At room temperature, take 100g of titanium oxide-alumina composite oxide (A-1), impregnate it with the previously prepared impregnation solution, dry it at 120°C for 4 hours, then calcinate it at 500°C for 4 hours, take it out and cool it to room temperature . The catalyst prepared in this way is designated Catalyst 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com