Amorphous transparent PETG (Polyethylene Terephthalate Glycol) copolyester functional thin film and preparation method thereof

A copolyester, transparent technology, applied in the field of transparent polyester film and its preparation, to achieve the effect of high-efficiency shielding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

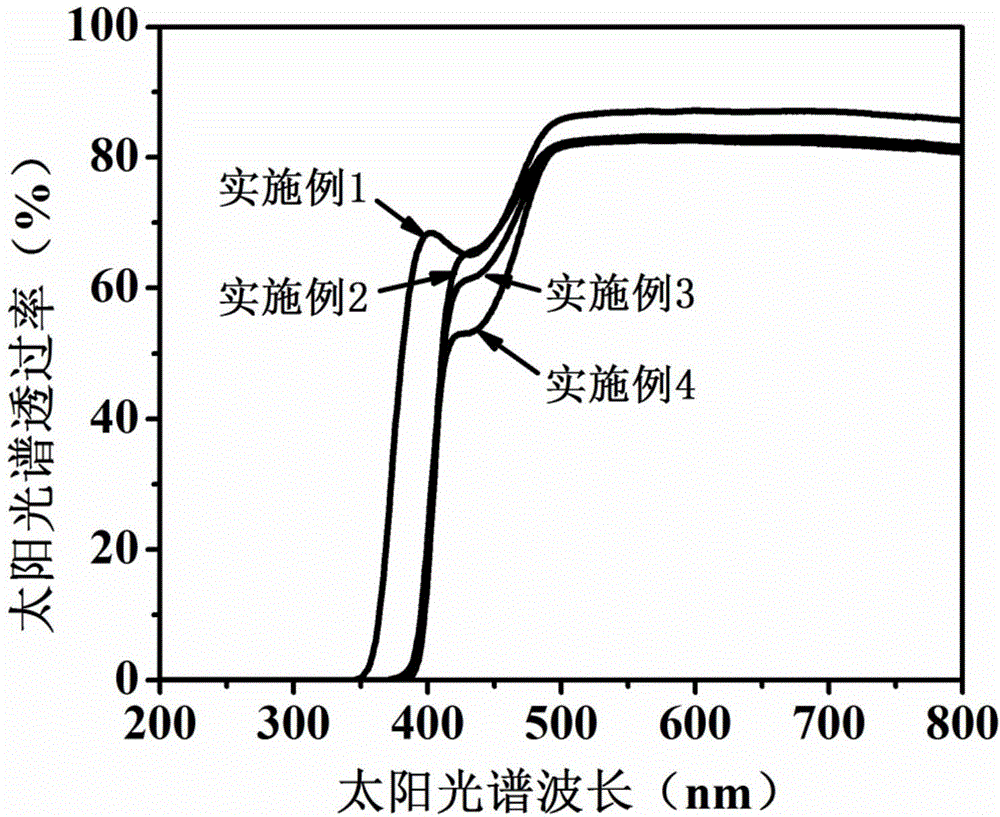

Embodiment 1

[0040] The mass ratio of raw materials is: PETG resin (intrinsic viscosity 0.80dL g -1 , the molar ratio of CHDM / EG is 30 / 70) 100, benzophenone UV absorber UV 5310.45, pigment permanent yellow 0.005, antioxidant 2,5-ditertbutyl hydroquinone 0.2, anti-oxidant Oxygen agent Hostanos P-EPQ 0.1, ethylene bis stearic acid amide 0.4.

[0041] Preparation method: Put 10 parts of PETG resin and all ultraviolet light absorbers, pigments, antioxidants and lubricants in the formula of amorphous transparent PETG copolyester functional film into a high-speed mixer, and control the speed of the mixer below 500rpm Stir at low speed for 3 minutes and discharge to the twin-screw extruder; the strong shear of the material through the twin-screw extruder makes the additives in the formula evenly dispersed in the PETG resin matrix, and finally the functional masterbatch is obtained by the pelletizer. Among them, the granulation and molding control conditions of the twin-screw extruder are as foll...

Embodiment 2

[0043] The mass ratio of raw materials is: PETG resin (intrinsic viscosity 0.85dL g -1 , the molar ratio of CHDM / EG is 30 / 70) 100, benzophenone UV absorber UV 3260.5, pigment permanent yellow 0.005, antioxidant 2,5-ditertbutyl hydroquinone 0.1, anti-oxidant Oxygen agent Hostanos P-EPQ 0.1, ethylene bis stearic acid amide 0.3, erucic acid amide 0.3.

[0044]Preparation method: Put 10 parts of PETG resin and all ultraviolet light absorbers, pigments, antioxidants and lubricants in the formula of amorphous transparent PETG copolyester functional film into a high-speed mixer, and control the speed of the mixer below 500rpm Stir at low speed for 5 minutes and discharge to the twin-screw extruder; the strong shear of the material through the twin-screw extruder makes the additives in the formula evenly dispersed in the PETG resin matrix, and finally the functional masterbatch is obtained by the pelletizer. Among them, the granulation and molding control conditions of the twin-screw...

Embodiment 3

[0046] The mass ratio of raw materials is: PETG resin (intrinsic viscosity 0.82dL g -1 , the molar ratio of CHDM / EG is 32 / 68) 100, benzophenone UV absorber UV P 0.1, benzophenone UV absorber UV 3260.5, pigment permanent yellow 0.010, antioxidant 2, 5-Di-tert-butyl hydroquinone 0.2, antioxidant Hostanos P-EPQ 0.1, ethylene bis stearic acid amide 0.2, erucic acid amide 0.2, zinc stearate 0.2.

[0047] Preparation method: Put 10 parts of PETG resin and all ultraviolet light absorbers, pigments, antioxidants and lubricants in the formula of amorphous transparent PETG copolyester functional film into a high-speed mixer, and control the speed of the mixer below 500rpm Stir at low speed for 4 minutes and discharge to the twin-screw extruder; the strong shear of the material through the twin-screw extruder makes the additives in the formula evenly dispersed in the PETG resin matrix, and finally the functional masterbatch is obtained by the pelletizer. Among them, the granulation and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com