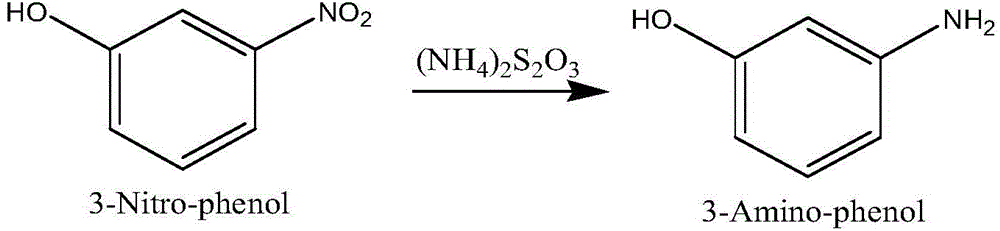

Novel method for preparing metaaminophenol by reducing metanitrophenol with byproduct ammonium thiosulfate recovered from coking desulfurization waste liquid

A technology for coking desulfurization waste liquid and ammonium thiosulfate, which is applied in the field of comprehensive utilization of waste resources, can solve the problems of serious environmental pollution, inconvenient use, and many three wastes, etc., and achieves the effects of simple process, simple equipment, and improved economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Embodiment 1: In four-neck bottle, add 1g m-nitrophenol. Then 20ml of ethanol and 10ml of water were added. Start heating and stirring; After all dissolving, add 6g purity and be 96.1% ammonium thiosulfate (NH 4 ) 2 S 2 o 3; Make it all dissolve; Reflux reaction at 80 DEG C; Stop reaction after 4 hours, cool to room temperature naturally; Have white crystal to separate out, the crystal that suction filtration separates out; Obtain product m-aminophenol after complete drying; Weighing is 0.71g, The yield is about 91%.

Embodiment 2

[0016] Embodiment 2: in four-neck bottle, add 1g m-nitrophenol. Then 80ml of ethanol and 40ml of water were added. Start heating and stirring. After all dissolving, add 6g purity and be 96.1% ammonium thiosulfate (NH 4 ) 2 S 2 o 3 . Let it all dissolve. The reaction was refluxed at 80°C. After 4 hours, the reaction was stopped and cooled to room temperature naturally. White crystals were precipitated, and the precipitated crystals were filtered with suction. The product is obtained after complete drying: m-aminophenol. The weighed weight was 0.68g. The yield is about 87.2%.

Embodiment 3

[0017] Embodiment 3: in four-neck bottle, add 1g m-nitrophenol. Then 200ml of ethanol and 80ml of water were added. Start heating and stirring. After all dissolving, add 6g purity and be 96.1% ammonium thiosulfate (NH 4 ) 2 S 2 o 3 . Let it all dissolve. The reaction was refluxed at 80°C. After 4 hours, the reaction was stopped and cooled to room temperature naturally. White crystals were precipitated, and the precipitated crystals were filtered with suction. The product is obtained after complete drying: m-aminophenol. The weighed was 0.74 g. The yield is about 94.9%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com