Auxiliary braking device for explosion-proof rubber-tired vehicle

An explosion-proof rubber-wheeled vehicle and auxiliary braking technology, applied in the direction of hydraulic brake transmission, brakes, brake components, etc., can solve problems such as brake failure, increase the auxiliary braking force, reduce the braking distance, The effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

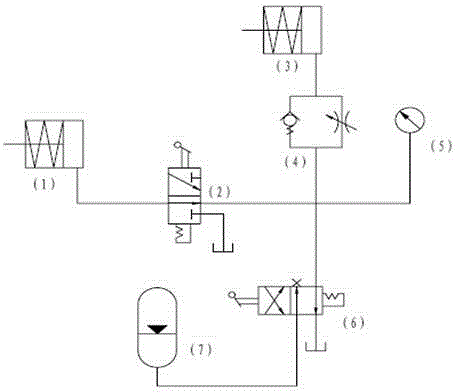

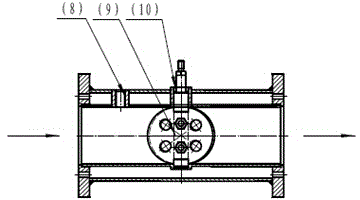

[0032] An auxiliary braking device for an explosion-proof rubber-tyred vehicle, including an actuator, a control system and a performance warning system. The actuator includes an explosion-proof water-cooled housing 8 connected to the exhaust system of an explosion-proof diesel engine, and a valve core 9 with a controllable throttle plate. , self-lubricating positioning sleeve 10 and valve core control mechanism 11, one end of the explosion-proof water-cooling housing 8 is connected to the explosion-proof water-cooling exhaust pipe, the other end is connected to the exhaust water washing box, and the explosion-proof water-cooling housing 8 is provided with threaded holes , the explosion-proof water-cooling shell 8 is provided with a valve core 9 with a controllable throttle plate, and the valve core 9 with a controllable throttle plate is fixedly connected with the flame-proof water-cooling shell 8 through a self-lubricating positioning sleeve 10, with a controllable throttle pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com