Coal-mine rubber-wheel all-hydraulic drilling machine

A fully hydraulic, rubber wheel technology, applied in drilling equipment, earthwork drilling, drilling equipment and methods, etc., can solve the problems affecting the efficient use of drilling rigs, labor intensity of workers, and labor intensity of relocation, etc., and achieve convenient installation and maintenance. Fast, flexible layout, large load/volume ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

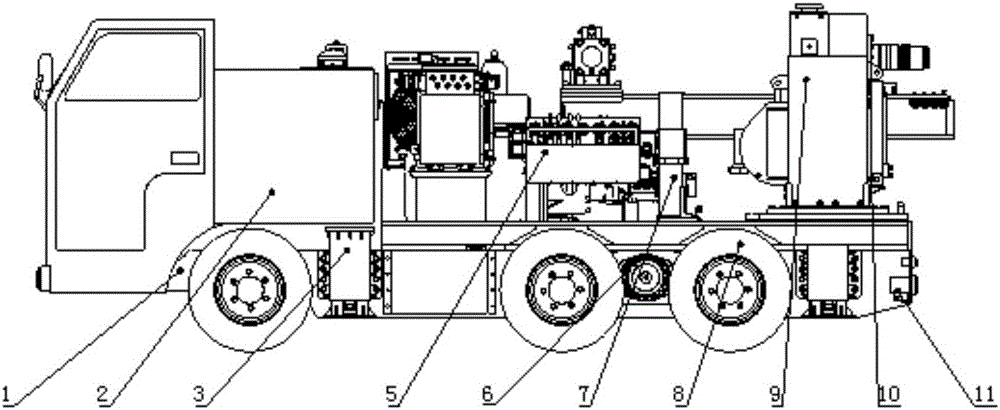

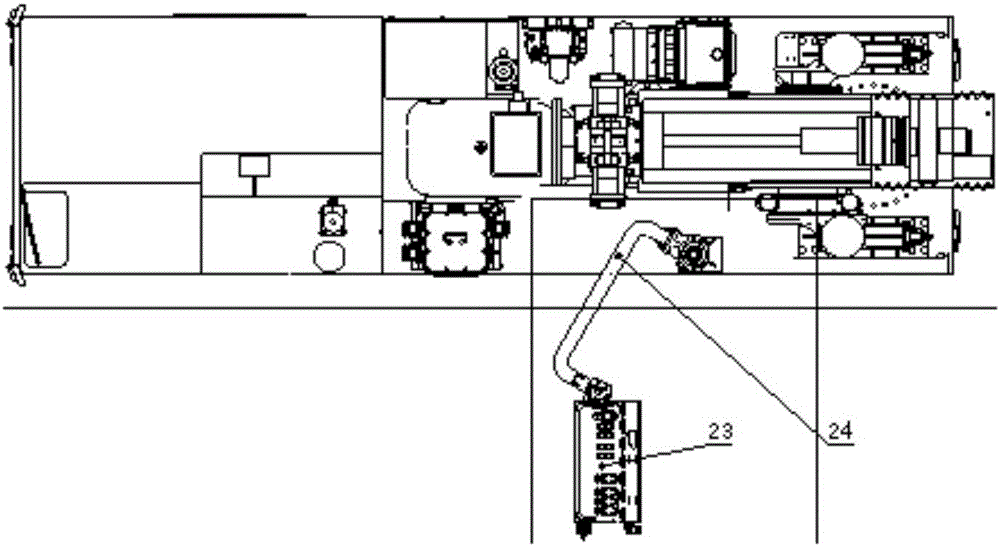

[0026] see figure 1 and 2 , has shown the rubber-wheeled full-hydraulic drilling rig for coal mines of the present invention.

[0027] The rubber-wheeled full-hydraulic drilling rig for coal mines comprises a rubber-wheeled walking chassis 1, and the rubber-wheeled walking chassis 1 may include a vehicle frame 12, and a traveling unit 6 and a plurality of pairs of walking rubbers are arranged below the vehicle frame 12. Wheels 8, at least include a pair of steering rubber wheels, at least a pair of driving wheels and at least a pair of driven wheels in multiple pairs of walking rubber wheels 8, the steering rubber wheels can also be driving wheels, and the vehicle frame 12 can also be set There is at least one lamp group 11 .

[0028] The front side of the rubber-wheeled walking chassis 1 is provided with a diesel engine power cabin 21 and a walking cockpit 22, which are arranged side by side at the front and parallel to the walking direction, wherein the walking cockpit 22 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com