Electro-hydraulic control system of disc type braking device of mine belt conveyor

An electro-hydraulic control system, belt conveyor technology, applied in conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as failure to brake, affect normal work, and block oil circuits, and achieve constant reduction. Speed braking, high reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

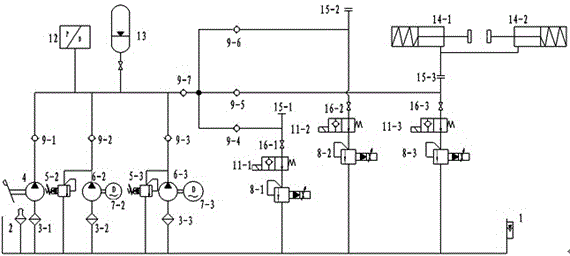

[0034] as attached figure 1As mentioned above, when the belt conveyor is working, a start signal is sent out, and after PLC processing, the electromagnetic reversing valve 11 is controlled to be energized to the left position, and at the same time the flameproof motor Ⅱ7-2 is started, driving the plunger pump Ⅱ6-2 to work from the oil tank Oil suction, the oil passes through the check valve Ⅱ9-2 to flush the accumulator 13, the oil flows through the check valve Ⅶ9-7 and is divided into multiple paths, any oil path passes through the check valve, and the oil is divided into two paths , one way enters the hydraulic cylinder of the brake head 14, the disc spring is compressed to release the brake head, and the other way flows to the electromagnetic reversing valve 11; after the pressure transmitter 12 detects that the system pressure reaches the set value, it returns to the PLC signal to control the explosion-proof motor Ⅱ7-2 to lose power, stop working, return a start signal to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com