Ferric hydroxide loaded rhodium-based catalyst and preparation and application thereof

An iron hydroxide and catalyst technology, applied in chemical instruments and methods, hydrogen, hydrogen separation and other directions, can solve the problems of complex preparation process, excessive particle size, Cl ion poisoning, etc., and achieves improved catalyst activity, simple preparation process, The effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

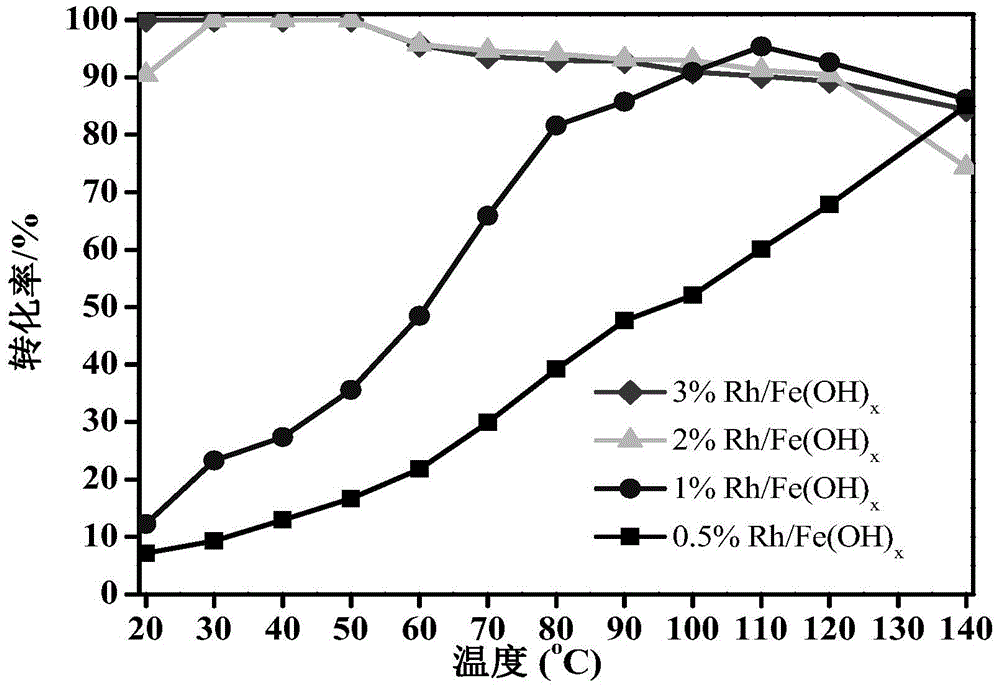

Embodiment 1

[0027] 3.78g of Fe(NO 3 ) 3 9H 2 O with 0.1wt% RhCl 3 ·3H 2 Add 2.02 g of O solution to 100 ml of ethylene glycol aqueous solution (ethylene glycol: water = 3: 1), then ultrasonically disperse and mix evenly, and add dropwise to 100 ml of 0.3 mol / L NaOH solution under strong stirring, and adjust the pH value to 8. Co-precipitation is formed, continue to stir at 80°C for 3h, stand still for 1h, filter, wash with hot water, place at 80°C for 12h to dry the catalyst, and obtain 0.2%Rh / Fe(OH) x catalyst.

Embodiment 2

[0029] 3.78g of Fe(NO 3 ) 3 9H 2 O with 0.10wt% RhCl 3 ·3H 2 Add 9.98g of O solution to 100ml of ethylene glycol aqueous solution (ethylene glycol: water = 3: 1), and then ultrasonically disperse and mix evenly, then add dropwise to 100ml of 0.3mol / L NaOH solution under strong stirring, and adjust the pH value to 8. Co-precipitation is formed, continue to stir at 80°C for 3h, stand still for 1h, filter, wash with hot water, place at 80°C for 12h to dry the catalyst, and obtain 1%Rh / Fe(OH) x catalyst.

Embodiment 3

[0031] 3.78g of Fe(NO 3 ) 3 9H 2 O with 0.1wt% RhCl 3 ·3H 2Add 20.01 g of O solution to 100 ml of ethylene glycol aqueous solution (ethylene glycol: water = 3: 1), then ultrasonically disperse and mix evenly, and add dropwise to 100 ml of 0.3 mol / L NaOH solution under strong stirring, and adjust the pH value to 8. Co-precipitation is formed, continue to stir at 80°C for 3h, stand still for 1h, filter, wash with hot water, place at 80°C for 12h to dry the catalyst, and obtain 2%Rh / Fe(OH) x catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

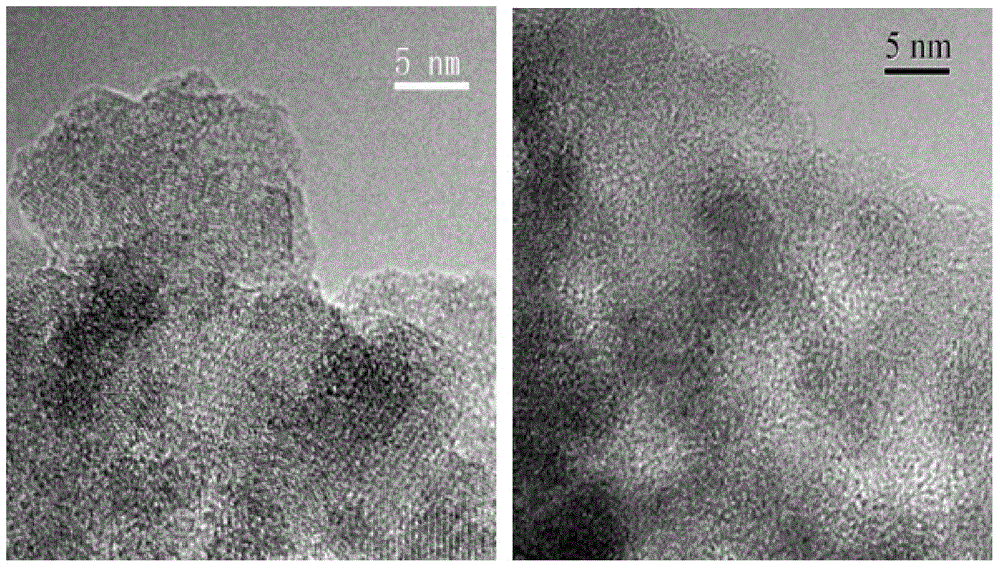

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com