A kind of polyester film for optical high permeability glue protection and preparation method thereof

A technology of polyester film and high-permeable adhesive, applied in the field of polyester film, can solve the problems of high surface roughness, high cost, and inability to remove defects, etc., and achieve substantial characteristics, excellent temperature resistance, and excellent products performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

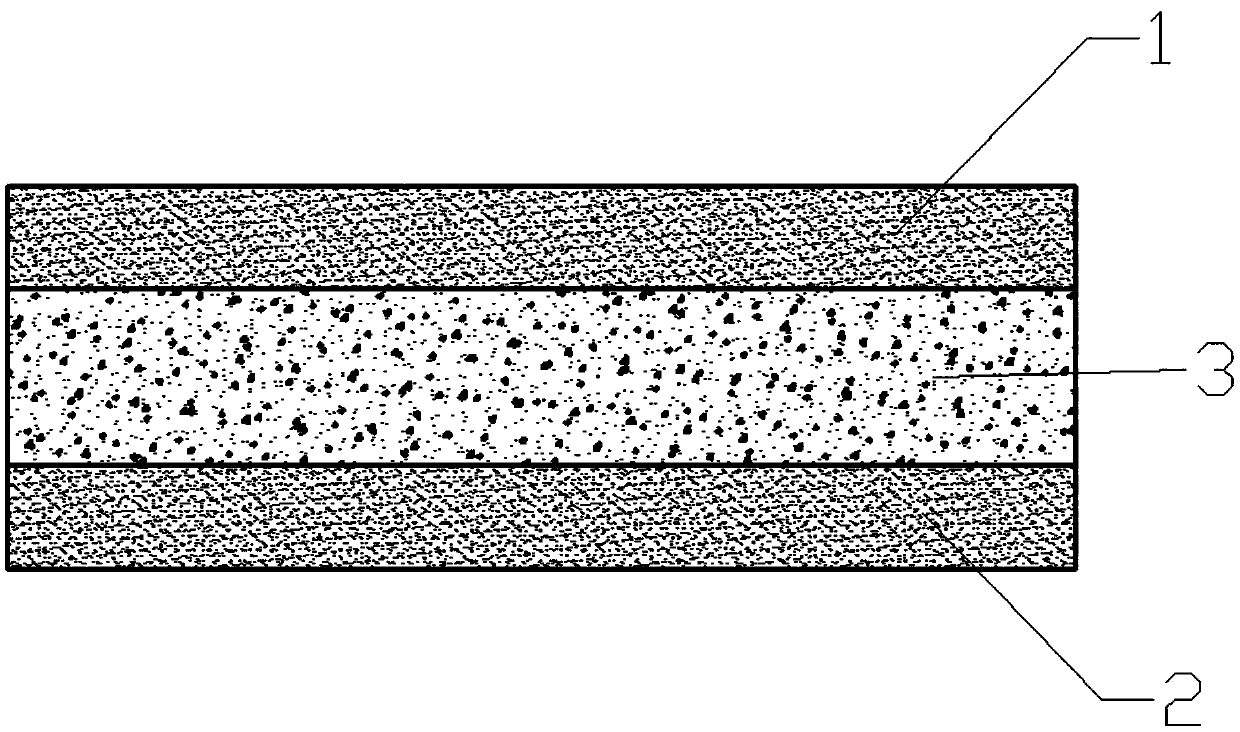

[0034] like figure 1 Shown, a kind of polyester film for optical high permeable glue protection, comprises the first base material layer 1, the second base material layer 2, intermediate core layer 3, the thickness of intermediate core layer 3 occupies 10% of the polyester film for optical high permeable adhesive protection. 60%-80% of the total thickness of the film, the first base material layer 1 and the second base material layer 2 respectively account for 10%-20% of the total thickness of the polyester film for optical high-permeability adhesive protection.

[0035] Wherein the middle core layer 3 is a polyester chip with a material purity of 99%-100%. The material composition of the first substrate layer 1 and the second substrate layer 2 is: 50%-70% nano-scale masterbatch MB10, 3%-5% nano-scale antistatic additive masterbatch ATS10, 47%-25% polyester Sliced; nano-grade MB10 masterbatch is made of 0.1%-1.2% nano-grade silica, 0.01%-0.1% particle size 1.0 micron-1.8 micr...

Embodiment 2

[0037] like figure 1 Shown, a kind of polyester film for optical high permeable glue protection, comprises the first base material layer 1, the second base material layer 2, intermediate core layer 3, the thickness of intermediate core layer 3 occupies 10% of the polyester film for optical high permeable adhesive protection. 65%-75% of the total thickness of the film, the first base material layer 1 and the second base material layer 2 respectively account for 12.5%-17.5% of the total thickness of the polyester film for optical high-permeability adhesive protection.

[0038]Wherein the middle core layer 3 is a polyester chip with a material purity of 99%-100%. The material composition of the first substrate layer 1 and the second substrate layer 2 is: 55%-65% nano-scale masterbatch MB10, 3%-5% nano-scale antistatic additive masterbatch ATS10, 30%-45% polyester Sliced; nano-grade MB10 masterbatch is made of 0.1%-1.2% nano-grade silica, 0.01%-0.1% particle size 1.0 micron-1.8 m...

Embodiment 3

[0040] like figure 1 Shown, a kind of polyester film for optical high permeable glue protection, comprises the first base material layer 1, the second base material layer 2, intermediate core layer 3, the thickness of intermediate core layer 3 occupies 10% of the polyester film for optical high permeable adhesive protection. 80% of the total thickness of the film, the first substrate layer 1 and the second substrate layer 2 respectively account for 10% of the total thickness of the polyester film for optical high-permeable adhesive protection.

[0041] Wherein the middle core layer 3 is a polyester chip with a material purity of 99.8%. The material composition of the first substrate layer 1 and the second substrate layer 2 is: 70% nanoscale masterbatch MB10, 4% nanoscale antistatic additive masterbatch ATS10, 26% polyester chip; nanoscale MB10 masterbatch is made of 1% nano-scale silica, 0.05% particle size 1.0 micron-1.8 micron silica, 0.05% kaolin, 0.5% silane coupling agen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com