Medical tooth root post composite material

A composite material and root post technology, used in dentistry, medical science, dental preparations, etc., can solve the problem of high price and achieve the effects of simple operation, strong market competitiveness and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

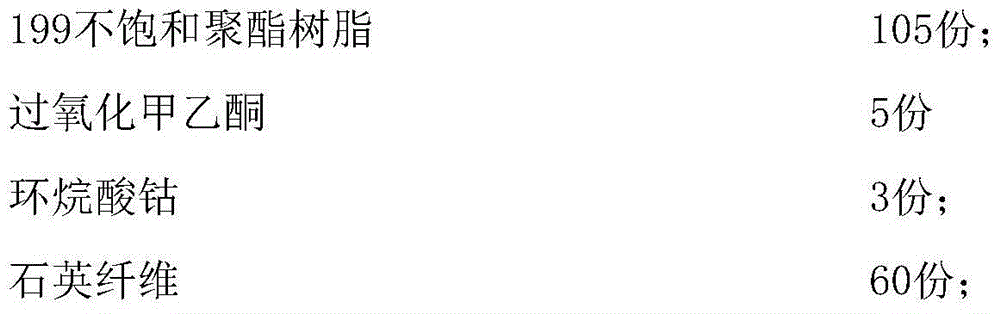

[0021] The composite material of the medical tooth root post has the following composition and mass ratio:

[0022] Component A:

[0023]

[0024] Component B:

[0025] 1 part thermochromic powder;

[0026] 12 parts of 191 unsaturated polyester resin.

[0027] Mix component A:component B according to the mass ratio of 10:3; then put it into the extruder, and extrude it in a stick shape at a temperature of 80-120°C. Cut the package according to the size of the root post.

Embodiment 2

[0029] The composite material of medical tooth root post of the present invention, its component and mass fraction ratio are as follows:

[0030] Component A:

[0031]

[0032] Component B:

[0033] 2 parts of thermochromic powder;

[0034] 10 parts of unsaturated polyester resin.

[0035] Mix component A:component B according to the mass ratio of 10:3; then put it into the extruder, and extrude it in a stick shape at a temperature of 80-120°C. Cut the package according to the size of the root post.

[0036] Mix component A:component B according to the mass ratio of 10:3; then put it into the extruder, and extrude it in a stick shape at a temperature of 80-120°C. Cut the package according to the size of the root post.

Embodiment 3

[0038] The composite material of medical tooth root post of the present invention, its component and mass fraction ratio are as follows:

[0039] Component A:

[0040]

[0041] Component B:

[0042] 1 part thermochromic powder;

[0043] 8 parts of 196 unsaturated polyester resin.

[0044] Mix component A:component B according to the mass ratio of 10:3; then put it into the extruder, and extrude it in a stick shape at a temperature of 80-120°C. Cut the package according to the size of the root post.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com