Method, structure and device for improving contact reliability of electric brush and reverser of direct current speed measuring power generator

A tachogenerator and commutator technology, which is applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of output voltage wave formation sheet burrs, system jitter, burrs, etc., to achieve continuous and stable force, improve Reliable contact and the effect of reducing contact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

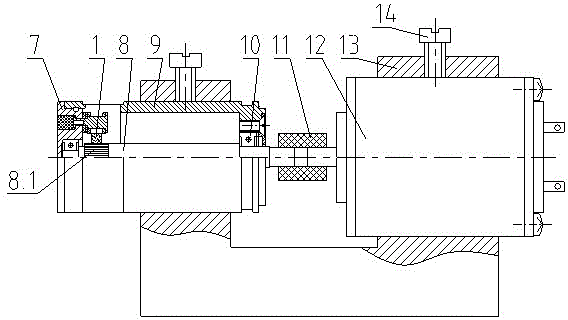

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

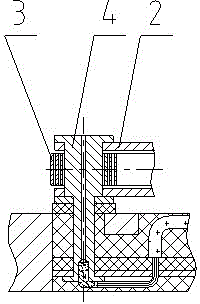

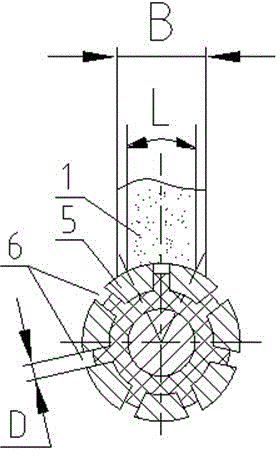

[0022] Embodiments of the present invention: a method for improving the contact reliability of DC tachogenerator brushes and commutators in the present invention can be directly used for brushed DC tachogenerators in the prior art, especially requiring extremely low starting voltage The miniature brushed DC servo motor is produced and implemented. The method includes a DC tachogenerator that presses the brush through a scroll spring, and the scroll spring is installed on the brush box, and the brush box is installed and fixed on the brush box through a terminal post. On the brush holder ring of the end cover of the DC tachometer generator, the gap between the installation hole on the brush box and the terminal post is controlled at 0.015mm to 0.08mm during production, and at the same time, the width of the brush is made equal to or greater than...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Groove width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com