Flexible manipulator

A technology of manipulators and flexible fingers, applied in the field of flexible manipulators, can solve problems such as high difficulty in installation and maintenance, limited service life and compressive strength, and low reliability, so as to reduce external pipeline connections, improve air tightness, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

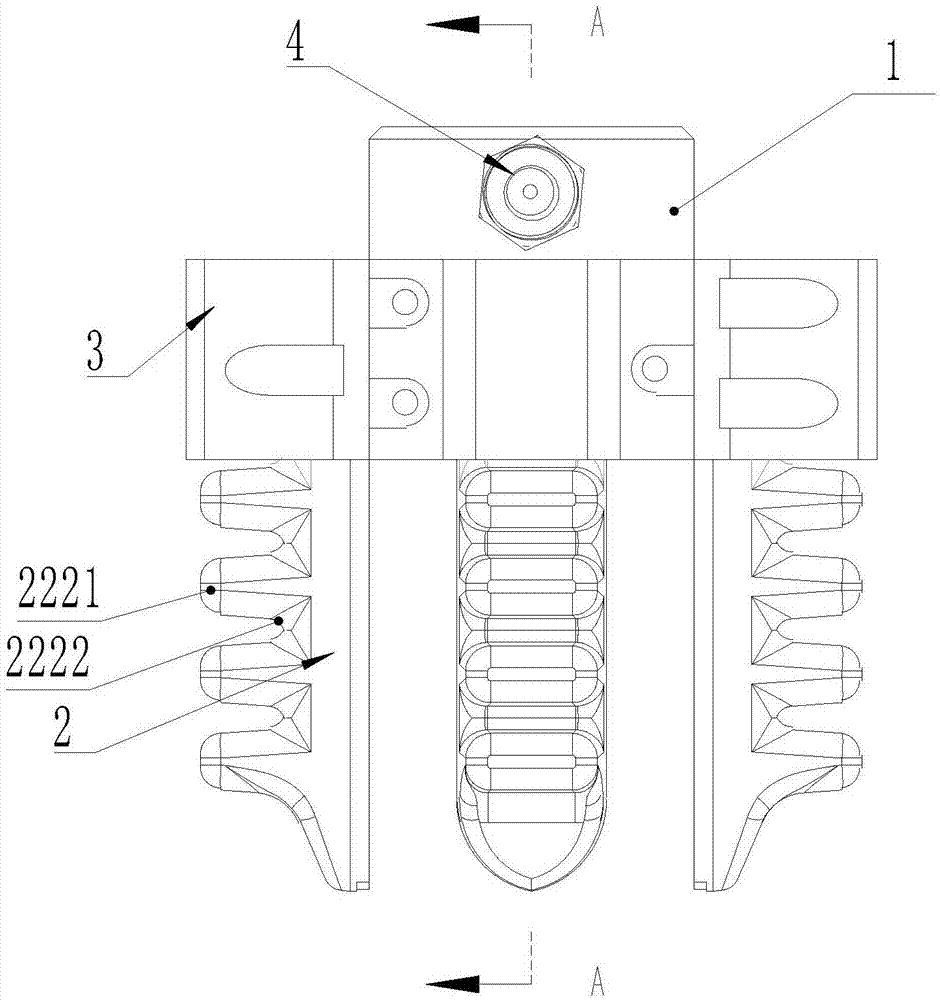

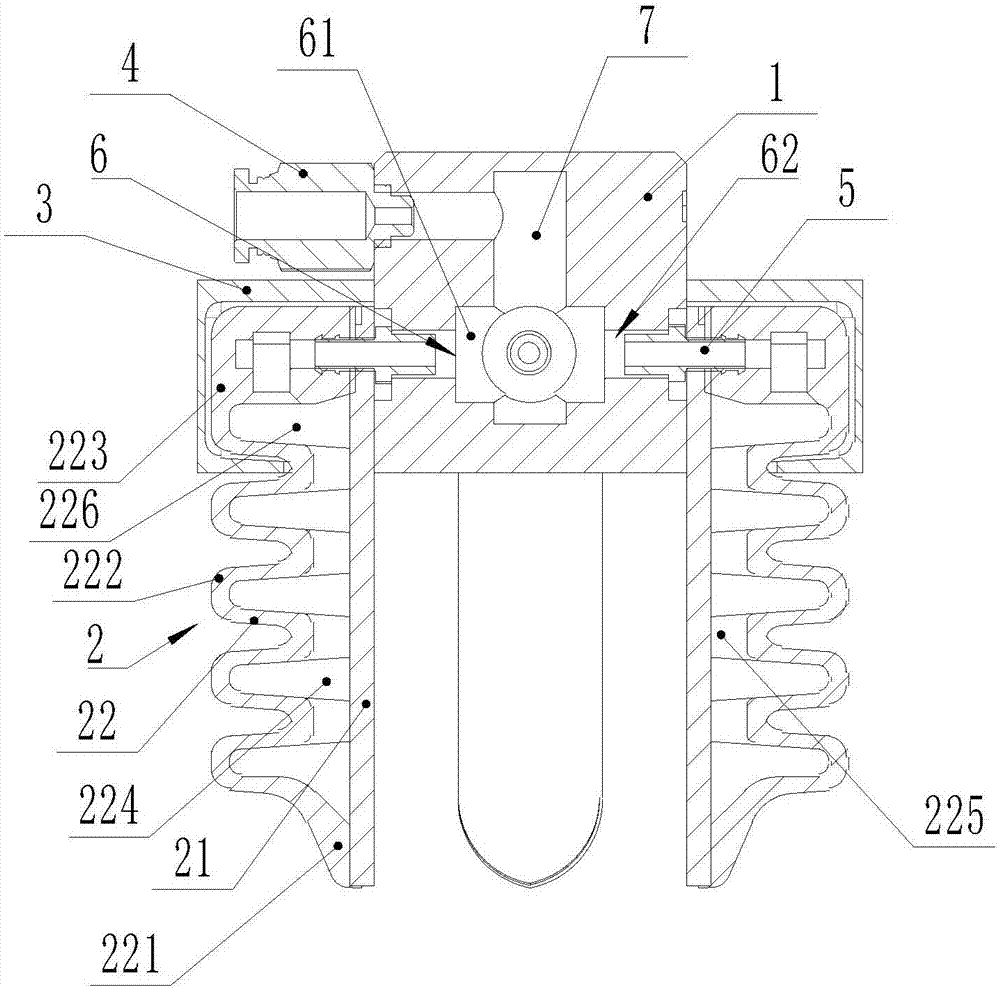

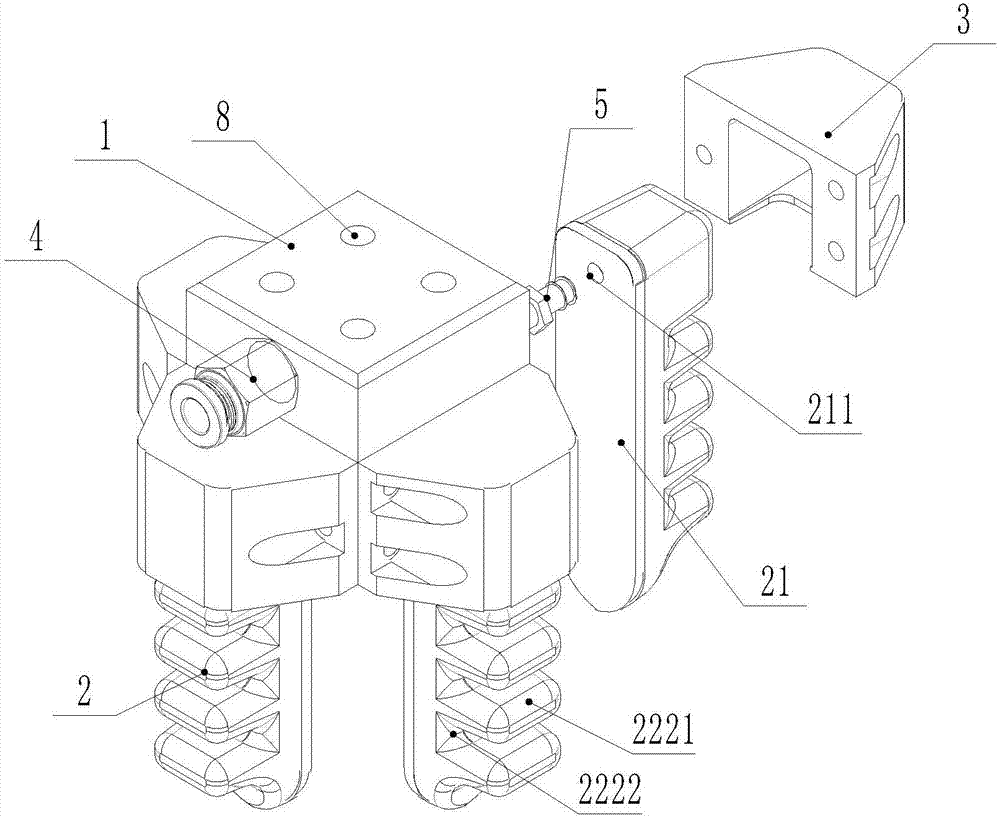

[0035] Such as Figure 1 to Figure 5 As shown, a flexible manipulator includes at least one pair of flexible fingers 2. The number of flexible fingers 2 can be optimally selected according to the items to be grasped, and the number can be two, three, four or more.

[0036] The flexible manipulator also includes a distribution manifold 1, the distribution manifold 1 is provided with a main channel 7 and several sub-channels 6, each sub-channel 6 is provided with a tap 5, and the main channel 7 is provided with There is a main joint 4, wherein, the distribution manifold 1 includes installation sides 8 equal in number to the number of flexible fingers 2, and each installation side 8 forms a regular polygon, for example, after the flexible fingers 2 are installed, they can be distributed into regular triangles, squares or regular fives. side shape, etc., so that the cooperative clamping of flexible fingers 2 can clamp irregular items. In this embodiment, the number of flexible fi...

Embodiment 2

[0042] The structure of this embodiment is basically the same as that of Embodiment 1, except that there are two flexible fingers 2 in this embodiment, so the installation side 8 of the distribution integrated block 1 is also two and set oppositely, and the flexible fingers 2 are set oppositely. Its fixing method is the same as that of embodiment 1.

[0043] However, in this embodiment, the reinforcing structure includes reinforcing pieces 228 equal in number to the troughs 2222 , and the reinforcing pieces 228 are embedded in the bottoms of the troughs 2222 one by one. Reinforcement sheet 228 adopts fiber reinforcement sheet 228, and this reinforcement sheet 228 can improve compressive strength equally, prolongs service life. Of course, in this embodiment, the other side of the finger bottom plate 21 is provided with a rough structure that increases friction. The rough structure can be a protrusion 212 or a groove, and the protrusion 212 can be a spherical protrusion 212 or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com