Continuous esterification technique for producing biodiesel from waste grease

A technology for waste oil and biodiesel, applied in fatty acid production, fatty acid esterification, biofuels and other directions, can solve the problems of high methanol and water content, unable to meet the needs of continuous production, unfavorable subsequent reactions, etc., and achieve process energy saving Environmentally friendly, extended dwell time, easy to handle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

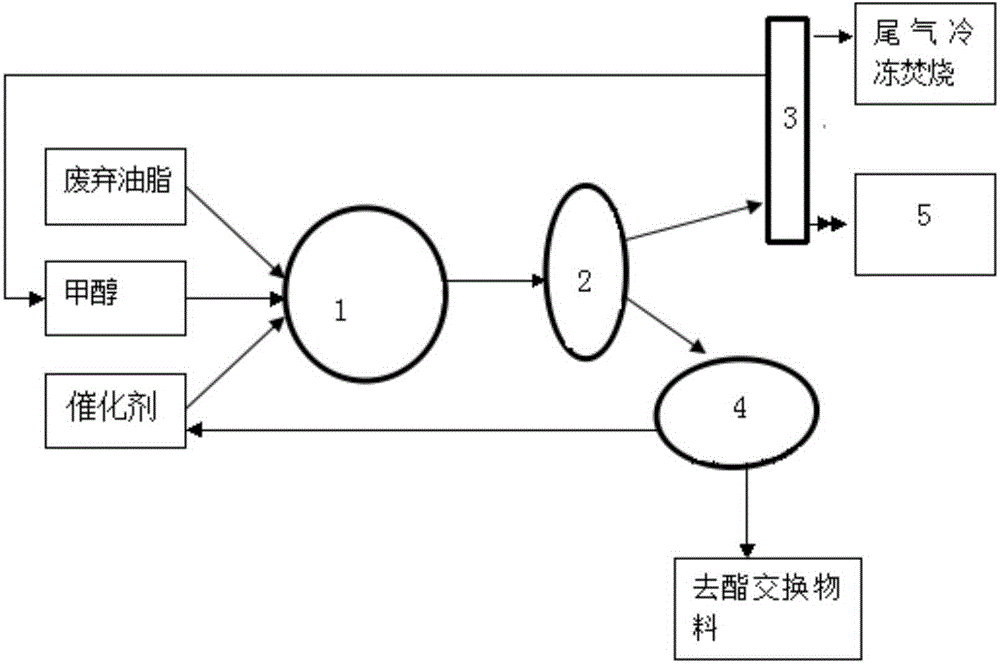

[0023] See figure 1 , the waste oil production biodiesel continuous esterification process of the present embodiment comprises the following steps:

[0024] Step 1: Continuously inject waste oil, catalyst and methanol into continuous esterification reactor 1 through a metering pump to carry out continuous esterification reaction and discharge; the catalyst is an organic acid; the temperature of the continuous esterification reaction is 65°C to 170°C, and the reaction The time is 13 to 20 minutes; the continuous esterification reactor 1 includes a cylinder body, a support and a heating device; the cylinder body is fixed on the support; the bottom and top of the cylinder body are respectively provided with a feed inlet and a discharge port; From bottom to top, the chamber consists of a material mixing section, a material heating reaction section and a material retention reaction section; the heating device is arranged in the material heating reaction section of the barrel. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com