Liquid crystal composition and display device comprising liquid crystal composition

A technology of liquid crystal composition and compound, which is applied in the direction of liquid crystal materials, instruments, chemical instruments and methods, and can solve problems such as slow polymerization speed, uneven alignment, and poor display

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

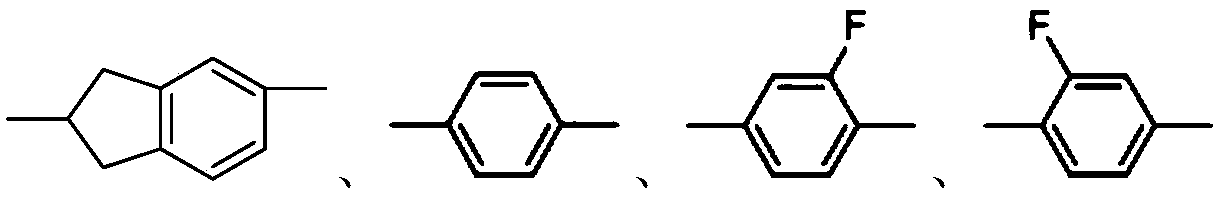

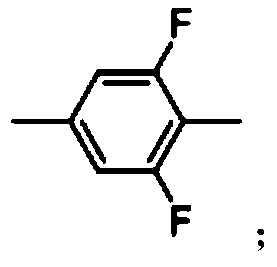

Method used

Image

Examples

Embodiment 1

[0082] Each compound listed in table 2 and percentage by weight are formulated into liquid crystal composition LC-1, as shown in table 2:

[0083] Table 2 The formula of liquid crystal composition LC-1

[0084]

[0085] Add 0.4% of compound II-5 to 99.6% of liquid crystal composition LC-1, dissolve uniformly, and obtain mixture MLC-1.

[0086]

[0087] There is no difference between the physical parameters of MLC-1 and those of LC-1.

[0088] The physical parameters of MLC-1 are: Δn: 0.091, Δε: -3.4, Cp: 80.

[0089] Inject MLC-1 into a test box with a gap of 4 μm and a homeotropic alignment using the vacuum infusion method. While applying a square wave with a frequency of 60 Hz and a driving voltage of 16 V, the test box is irradiated with ultraviolet rays by a high-pressure mercury ultraviolet lamp. , adjust the irradiation intensity to the surface of the box to be 30mW / cm 2 , irradiated for 360 seconds to obtain a vertically aligned liquid crystal display element a...

Embodiment 2

[0099] Test the pretilt angle and polymeric compound residual data of embodiment 1 and comparative example 1, experimental result is as shown in table 4 and table 5:

[0100] Table 4 Pretilt angle before and after UV light irradiation

[0101]

[0102] Polymer residue in the liquid crystal composition of table 5

[0103] UV polymerization time (s)

[0104] From the comparative data in Table 4 and Table 5, it can be seen that the liquid crystal composition of the present invention has better alignment effect, faster polymer rate, more complete polymerization, and lower residue, thereby greatly improving the problem of poor display. .

Embodiment 3

[0106] Each compound listed in table 6 and percentage by weight are formulated into liquid crystal composition LC-3, as shown in table 6:

[0107] Table 6 The formula of liquid crystal composition LC-3

[0108]

[0109] Add 0.4% of compound II-5 to 99.6% of the liquid crystal composition LC-3, dissolve uniformly, and obtain the mixture MLC-3.

[0110]

[0111] There is no difference between the physical parameters of MLC-3 and those of LC-3.

[0112] The physical parameters of MLC-3 are: Δn: 0.105, Δε: -2.8, Cp: 75.2.

[0113] Inject MLC-3 into a test box with a gap of 4 μm and a homeotropic alignment using a vacuum infusion method. While applying a square wave with a frequency of 60 Hz and a driving voltage of 16 V, the test box is irradiated with ultraviolet rays by a high-pressure mercury ultraviolet lamp. , adjust the irradiation intensity to the surface of the box to be 30mW / cm 2 , irradiated for 360 seconds to obtain a vertically aligned liquid crystal display e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com