Epoxy molding compound and preparation method thereof

An epoxy molding compound and epoxy technology, applied in the field of integrated circuit packaging, can solve the problems of unsatisfactory thermal properties, mechanical properties and electrical properties of epoxy molding compounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

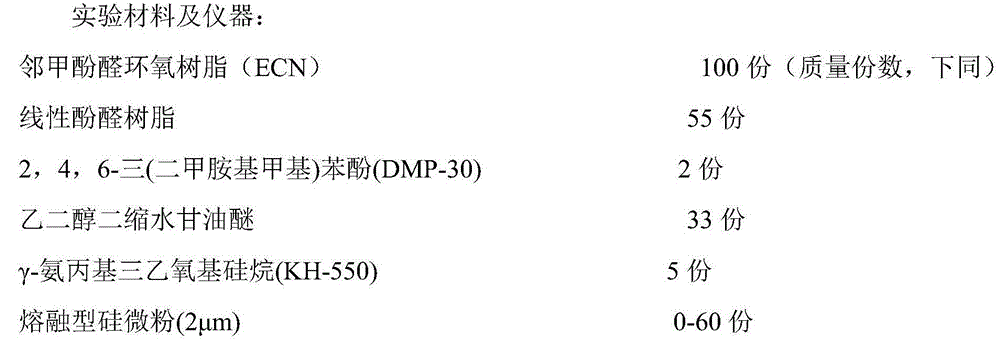

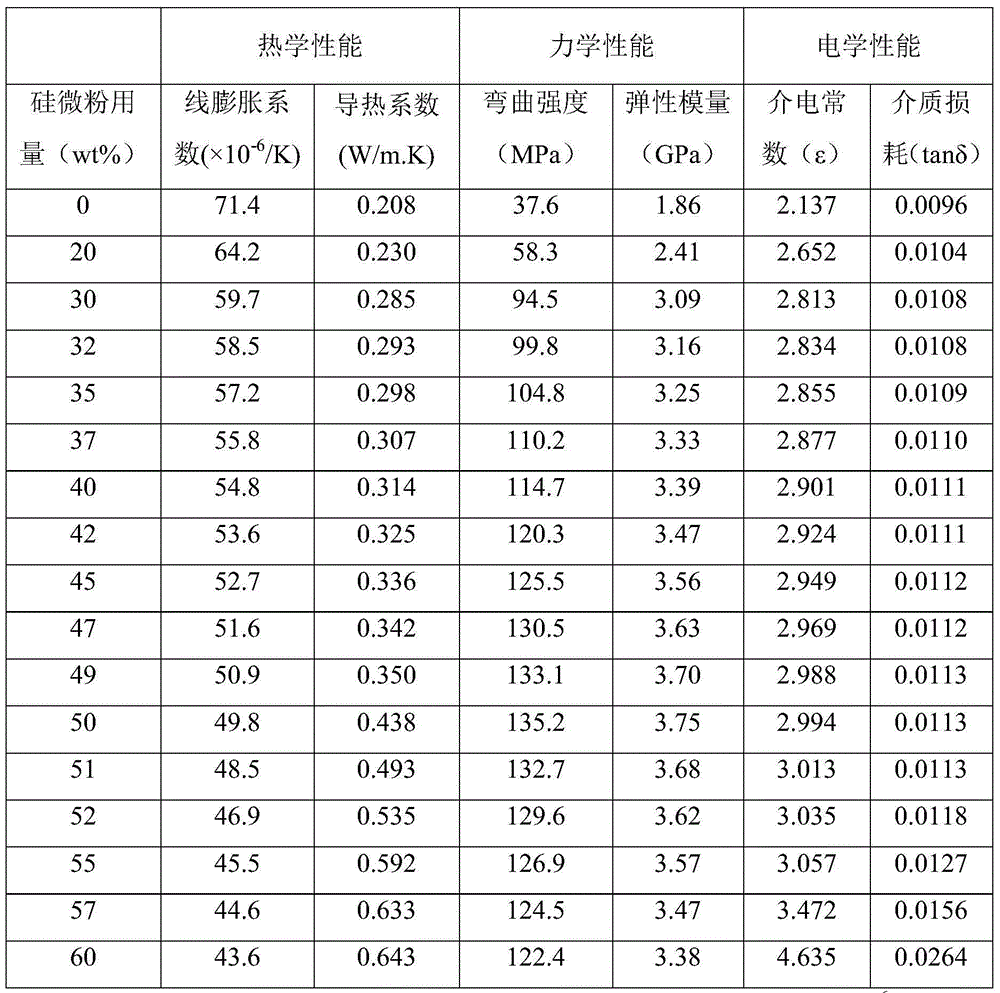

[0038] The purpose of this embodiment is to study the influence of the amount of fused silica powder on the thermal, mechanical and electrical properties of EMC. That is, use 5% (mass percentage) coupling agent solution to carry out coupling modification on the molten silicon powder (the average particle size obtained after ball milling for 24 hours is 2 μm) of ball milling 24h (2μm), and the test is different. The linear expansion coefficient, thermal conductivity, bending strength, elastic modulus, dielectric constant and dielectric loss of the EMC with the amount of silica powder.

[0039]

[0040] Electronic analytical balance; JJ-3 constant temperature electric stirrer; DK-8B type electric heating constant temperature water tank; KQ5200DE type numerical control ultrasonic cleaner; NP-C-20-1500 in-line ultrasonic disperser; DZF-6020 vacuum drying oven.

[0041] Experimental steps:

[0042] 1. Weigh a certain amount of silica powder, put it in a drying oven at 110°C, an...

Embodiment 2

[0058] The purpose of this example is to study the influence of particle size of fused silica powder on the thermal and mechanical properties of EMC. That is, use 5% coupling agent solution to couple and modify the molten silicon micropowder milled for 16h, 24h, 30h, 38h, and 48h, and test the linear expansion coefficient, bending strength, and elastic modulus of EMC with an addition of 50%. quantity.

[0059] Experimental materials and steps:

[0060] Except that the addition amount of molten silicon micropowder is fixed at 50%, the others are the same as in Embodiment 1.

[0061] Experimental Results and Discussion:

[0062] Table 2 The effect of particle size of molten silicon micropowder on the thermal and mechanical properties of EMC

[0063] Silica powder particle size (μm)

Coefficient of linear expansion (×10 -6 / K)

Bending strength (MPa)

Elastic modulus (GPa)

[0064] no filler

71.4

37.6

1.86

Ball milling 16...

Embodiment 3

[0069] The purpose of this embodiment is to study the influence of different types of silica powder on the EMC linear expansion coefficient. That is, use 5% coupling agent solution to carry out coupling modification on silicon powder made from kaolin tailings, high-purity crystalline silicon powder, molten silicon powder, and silicon powder after secondary firing, and the test dosage is 60% When EMC linear expansion coefficient and thermal conductivity.

[0070] Experimental materials and procedures

[0071] Except that the added amount of various types of silicon micropowder is fixed at 60%, the others are the same as in the first embodiment.

[0072] Experimental Results and Discussion

[0073] Table 3 Effects of different silicon micropowders on EMC linear expansion coefficient and thermal conductivity

[0074] Types of Silica Powder

Coefficient of linear expansion (×10 -6 / K)

Thermal conductivity (W / m.K)

Silica powder made from kaolin tailings ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Linear expansion coefficient | aaaaa | aaaaa |

| Average linear expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com