Fiber-reinforced resin-based composite material core and preparation method thereof

A fiber-reinforced resin and fiber-reinforced material technology, which is applied in the field of composite material core and its preparation and amplification, can solve problems such as insufficient rigidity, insufficient hardness, and poor dimensional stability of products, so as to improve surface quality and pultrusion efficiency , promote the effect of obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

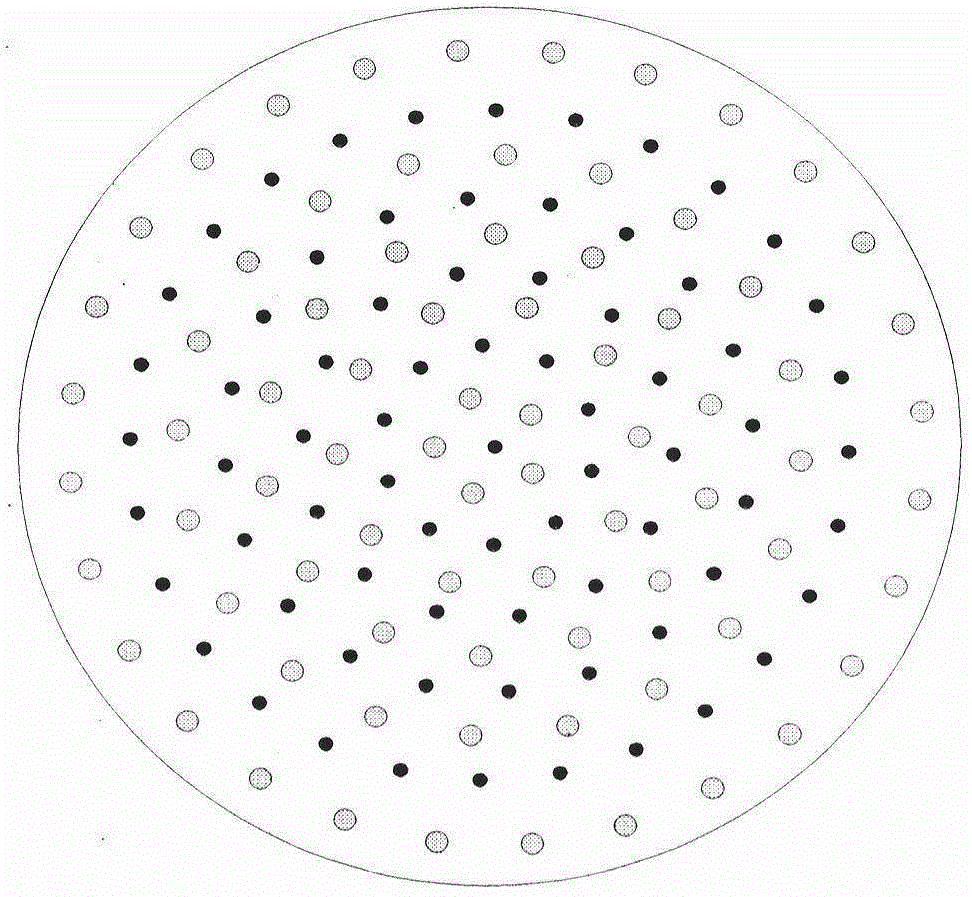

[0073] The fiber-reinforced resin-based composite material for the core of the fiber-reinforced resin-based composite material of the present invention is made of a resin material and a fiber-reinforced material, and the volume fraction is 30% for the resin material and 70% for the fiber-reinforced material;

[0074] Fiber-reinforced materials include 80% of high-strength glass fibers with a tensile strength of ≥3500MPa by volume fraction and 20% of high-strength carbon fibers with a tensile strength of ≥4900MPa by volume fraction, and the high-strength glass fibers and high-strength carbon fibers are evenly mixed;

[0075]The resin material comprises the following components by mass: 100 parts of thermosetting resin (diglycidyl tetrahydrophthalate epoxy resin), 70 parts of curing agent (m-xylylenediamine), accelerator (2-ethyl-4 -methylimidazole) 8 parts, filler (nano-TiO2) 2 parts, release agent (zinc stearate) 3 parts.

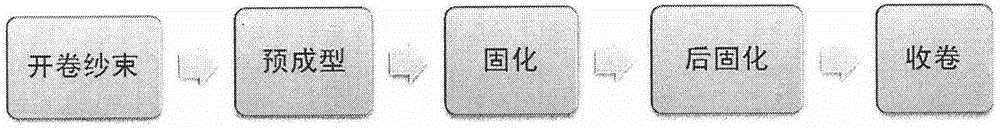

[0076] The preparation steps are as follows:

[0077...

Embodiment 2

[0095] The fiber-reinforced resin-based composite material for the core of the fiber-reinforced resin-based composite material of the present invention is made of a resin material and a fiber-reinforced material, and the volume fraction is 50% for the resin material and 50% for the fiber-reinforced material;

[0096] Fiber-reinforced materials include 60% of high-strength glass fibers with a tensile strength of ≥3500MPa by volume fraction and 40% of high-strength carbon fibers with a tensile strength of ≥4900MPa by volume fraction, and the high-strength glass fibers and high-strength carbon fibers are evenly mixed;

[0097] The resin material comprises the following components by mass: 100 parts of resin (1,4-butanediol diglycidyl ether epoxy resin), 85 parts of curing agent (phthalic anhydride), accelerator (N, N-dimethyl benzylamine) 1 part, filler (nano-SiO2) 2 parts, mold release agent (stearic acid) 1 part.

[0098] The preparation steps of the composite material are the ...

Embodiment 3

[0106] The fiber-reinforced resin-based composite material for the core of the fiber-reinforced resin-based composite material of the present invention is made of a resin material and a fiber-reinforced material, and the volume fraction is 80% for the resin material and 20% for the fiber-reinforced material;

[0107] Fiber-reinforced materials include 80% of high-strength glass fibers with a tensile strength of ≥3500MPa by volume fraction and 20% of high-strength carbon fibers with a tensile strength of ≥4900MPa by volume fraction, and the high-strength glass fibers and high-strength carbon fibers are evenly mixed;

[0108] The fiber-reinforced resin-based composite material for power grid transmission lines according to the present invention, according to the following proportions: 100 parts of resin (melamine epoxy resin), 230 parts of curing agent (diphenyl ether tetraacid dianhydride), accelerator (triethanolamine ) 25 parts, filler (BaTiO3) 10 parts, release agent (polydim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com