Photocatalytic auxiliary cutter sharpening method and device for diamond cutter

A diamond tool, photocatalytic technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, polishing compositions containing abrasives, etc., can solve the problems of low production cost, high surface roughness, long sharpening time, etc. The effect of good sharpening quality, high polishing efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

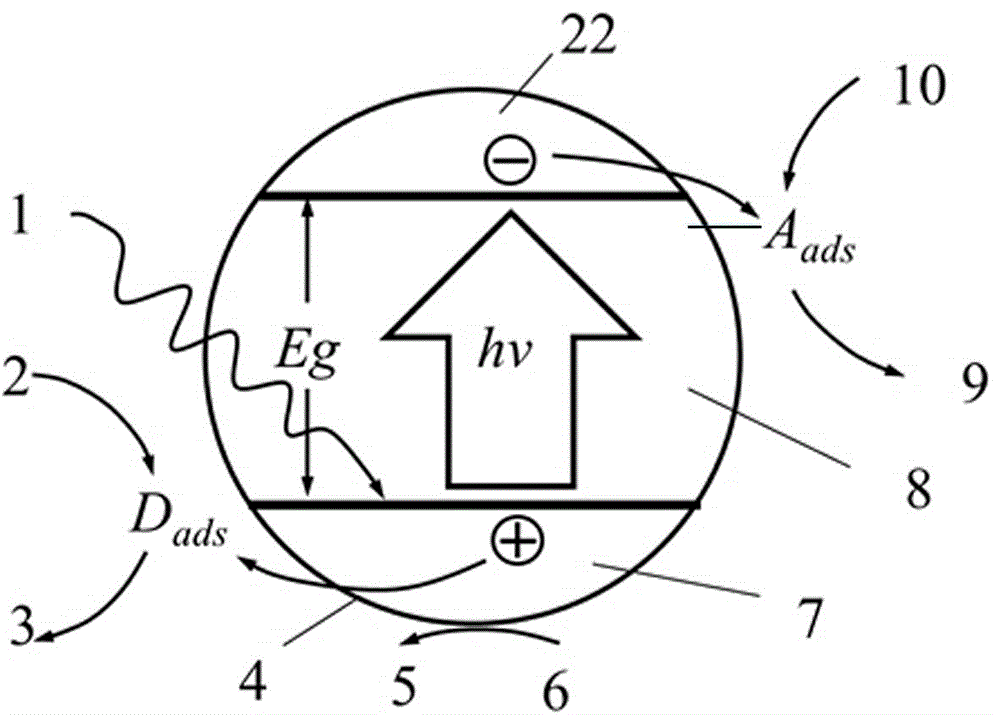

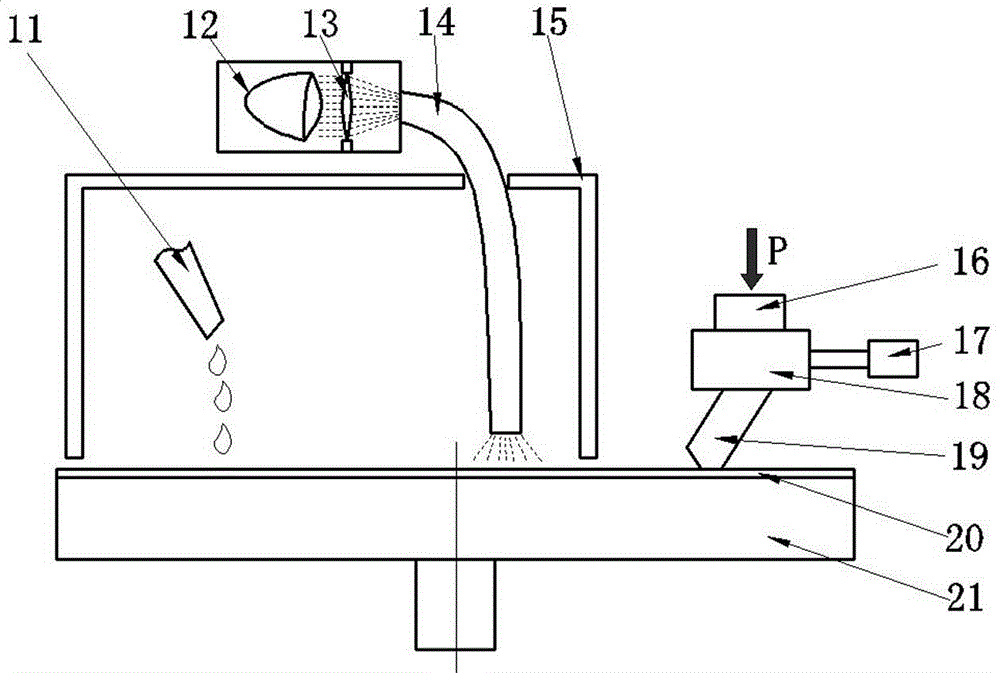

[0020] The polishing principle of the present invention is: when the nano-titanium dioxide is irradiated by ultraviolet light with a wavelength less than 387.5nm, the electrons in the valence band will be excited to the conduction band, and electrons and holes will be generated on the surface of the titanium dioxide particles. Electrons can be captured by electron capture agents such as potassium ferrate or hydrogen peroxide to avoid recombination with holes and reduce chemical interactions. The standard oxidation-reduction potential of the hole is 3.2V, which has a strong oxidizing property and can convert the OH adsorbed on the surface of titanium dioxide particles to - and H 2 O is oxidized to generate strong oxidizing hydroxyl radical·OH (the standard redox potential is 2.76V). Diamond can be oxidized when hydroxyl radicals come into contact with diamond. When polishing, the diamond tool is installed on the fixture, and the diamond tool is driven by a motor to rotate t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com