Preparation method of biodegradable nano-microsphere and application

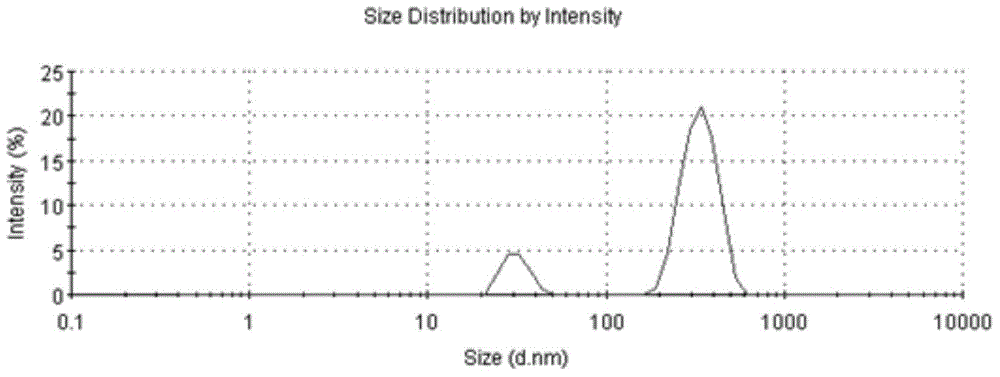

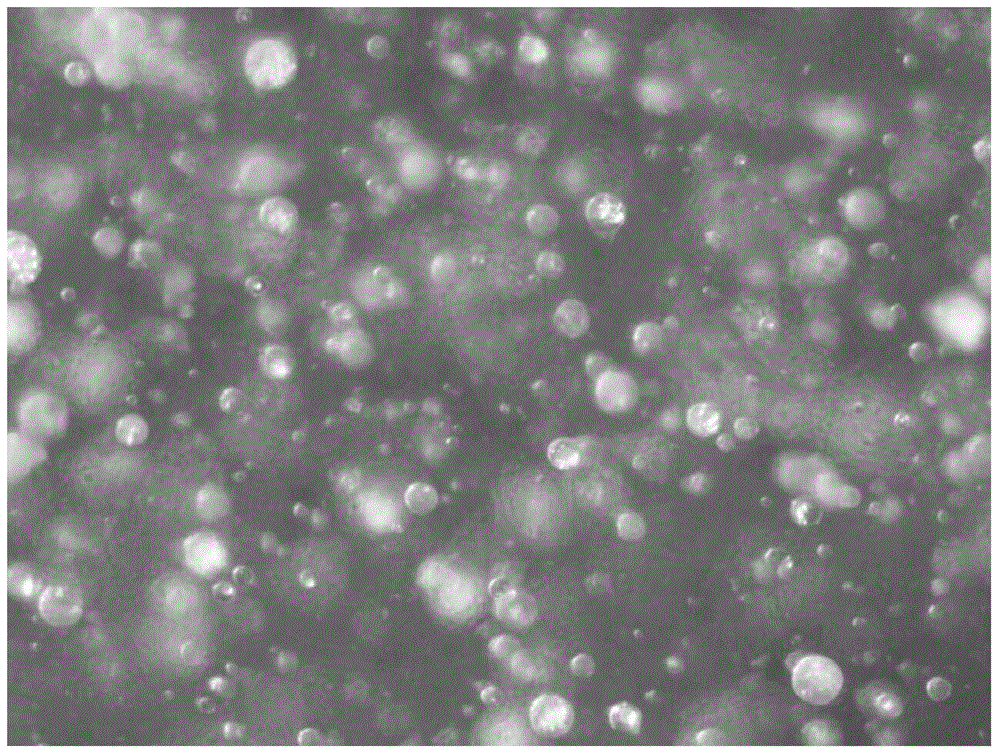

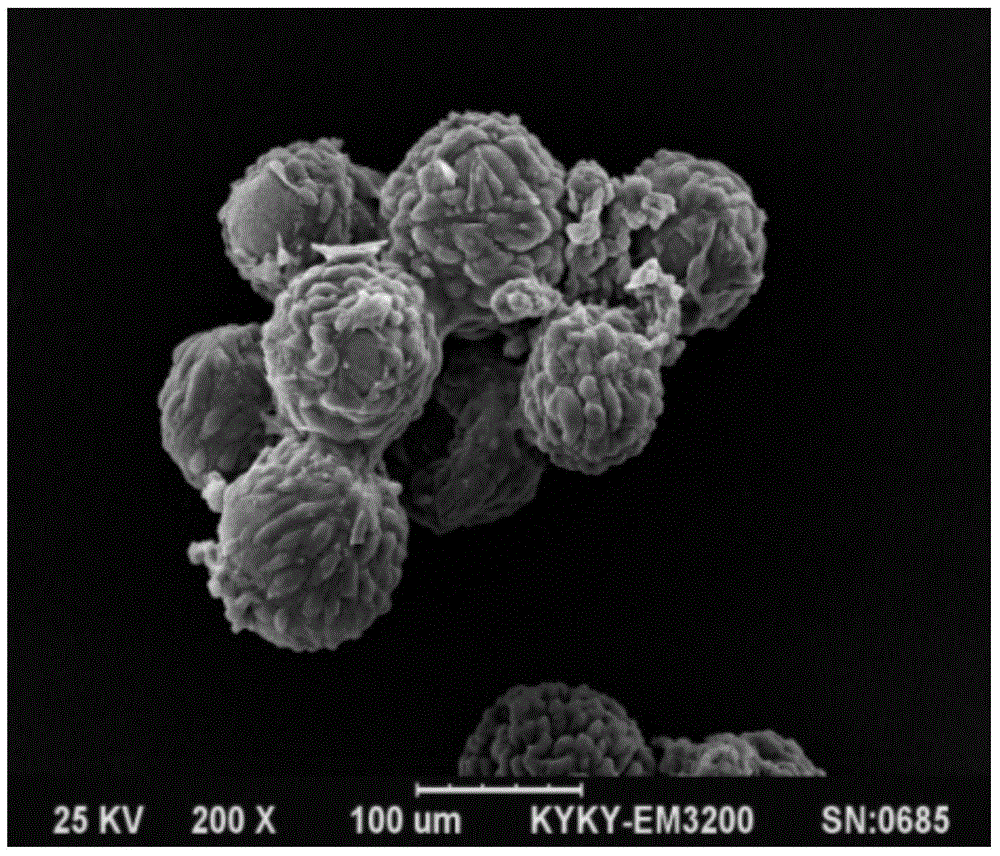

A nano-microsphere, biodegradable technology, used in medical science, prosthesis, etc., to achieve uniform particle size, improve facial contours, and simplify post-processing processes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The preparation method of the biodegradable nano microspheres of the present embodiment comprises the following steps:

[0040] Step 1, the viscosity average molecular weight is 6.0×10 5 PHB was dissolved in chloroform to obtain solution A; the mass percentage of PHB in solution A was 8%;

[0041]Step 2, adding the solution A obtained in step 1 into the emulsifier solution, and then placing it under ultrasonic waves for ultrasonic dispersion to obtain an emulsion; the volume of the emulsifier solution is 10 times the volume of the solution A; the emulsifier solution is obtained by The composition of the following mass percentage content: polyvinyl alcohol 1%, polyoxyethylene 0.10%, the balance is water; the temperature of the ultrasonic dispersion is 52 ℃, the power is 1000W, and the time is 18s; the polyvinyl alcohol The molecular weight is 7.7×10 4 , the molecular weight of polyoxyethylene is 2.5×10 6 ;

[0042] Step 3, carrying out negative pressure distillation ...

Embodiment 2

[0051] This example is the same as Example 1, except that the biodegradable material is PHBV, PHB-PEG copolymer, PLA, PLGA, PCL or PDLLA-PEG-PDLLA copolymer, or PHB, PHBV, At least two of PHB-PEG copolymer, PLA, PLGA, PCL, and PDLLA-PEG-PDLLA copolymer.

Embodiment 3

[0053] The preparation method of the biodegradable nano microspheres of the present embodiment comprises the following steps:

[0054] Step 1. Make the viscosity-average molecular weight 3.0×10 5 PHBV was dissolved in chloroform to obtain solution A; the mass percentage of PHBV in solution A was 5%;

[0055] Step 2, adding the solution A obtained in step 1 into the emulsifier solution, and then placing it under ultrasonic waves for ultrasonic dispersion to obtain an emulsion; the volume of the emulsifier solution is 15 times the volume of the solution A; the emulsifier solution is made of The composition of the following mass percentage content: polyethylene glycol 3%, polyoxyethylene 0.05%, the balance is water; the temperature of the ultrasonic dispersion is 55 ℃, the power is 900W, and the time is 15s; the polyethylene glycol The molecular weight of alcohol is 0.9×10 3 , the molecular weight of polyoxyethylene is 1.5×10 6 ;

[0056] Step 3, carrying out negative pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com