Preparation method for transparent silver nanowire conducting electrode

A technology of transparent conductive electrodes and silver nanowires, which is applied in the direction of cable/conductor manufacturing, conductive layers on insulating carriers, circuits, etc., can solve the problems of limiting the large-area application of nano-silver wires, time-consuming, and energy consumption, and achieve good results. The effect of application prospect, simple process, good light transmittance and electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

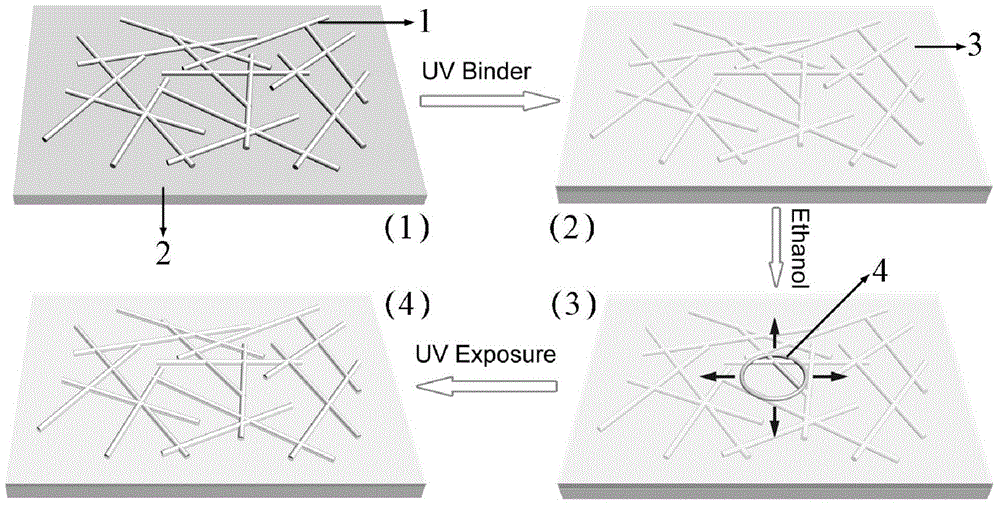

[0042] The preparation method of the nano-silver wire transparent conductive electrode provided in this embodiment, such as figure 1 As shown, wherein (1) means that nano-silver wires are drip-coated on PET substrates: 1 means nano-silver wires, 2 means substrates, (2) means that UV glue is applied to nano-silver wire films, and 3 means UV glue , (3) represents that absolute ethanol is dropped on the UV glue, 4 represents absolute ethanol; (4) represents the silver nanowire transparent conductive film after ultraviolet exposure. It mainly includes five steps: 1. Preparation of silver nanowires with high aspect ratio by polyol method; 2. Hydrophilic treatment of the substrate; 3. Coating the prepared silver nanowire solution on the substrate, drying at room temperature, Obtain the silver nanowire transparent conductive film; four, carry out the adhesion treatment to the silver nanowire transparent conductive film and the substrate; five, the silver nanowire transparent conducti...

Embodiment 2

[0060] The preparation method of the nano-silver wire transparent conductive electrode provided in this embodiment, such as figure 1 As shown, wherein (1) means that nano-silver wire is drip-coated on the PI substrate: 1 means nano-silver wire, 2 means substrate, (2) means that UV glue is applied to nano-silver wire film, and 3 means UV glue , (3) represents that absolute ethanol is dropped on the UV glue, 4 represents absolute ethanol; (4) represents the silver nanowire transparent conductive film after ultraviolet exposure. It mainly includes five steps: 1. Preparation of silver nanowires with high aspect ratio by polyol method; 2. Hydrophilic treatment of the substrate; 3. Coating the prepared silver nanowire solution on the substrate, drying at room temperature, Obtain the silver nanowire transparent conductive film; four, carry out the adhesion treatment to the silver nanowire transparent conductive film and the substrate; five, the silver nanowire transparent conductive ...

Embodiment 3

[0079] The preparation method of the nano-silver wire transparent conductive electrode provided in this embodiment, such as figure 1 As shown, wherein (1) means that nano-silver wire is drip-coated on the PI substrate: 1 means nano-silver wire, 2 means substrate, (2) means that UV glue is applied to nano-silver wire film, and 3 means UV glue , (3) represents that absolute ethanol is dropped on the UV glue, 4 represents absolute ethanol; (4) represents the silver nanowire transparent conductive film after ultraviolet exposure. It mainly includes five steps: 1. Preparation of silver nanowires with high aspect ratio by polyol method; 2. Hydrophilic treatment of the substrate; 3. Coating the prepared silver nanowire solution on the substrate, drying at room temperature, Obtain the silver nanowire transparent conductive film; four, carry out the adhesion treatment to the silver nanowire transparent conductive film and the substrate; five, the silver nanowire transparent conductive ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com