Preparation method of enhanced type Fe-Ni-Co-based high temperature alloy through precipitation

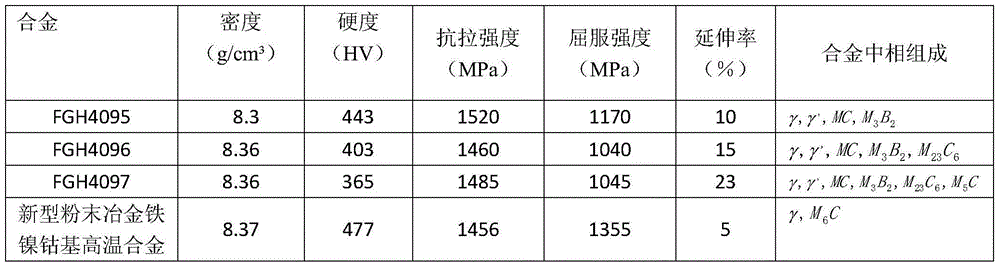

A superalloy and precipitation strengthening technology is applied in the field of preparation of precipitation-strengthened iron-nickel-cobalt-based superalloys, which can solve the problems of uneven mechanical properties, expensive powder sintering equipment for powder sintering, serious alloy segregation, etc. The effect of low cost, low cost of powder sintering, and simple strengthening phase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A method for preparing a precipitation-strengthened iron-nickel-cobalt-based superalloy, comprising the following steps:

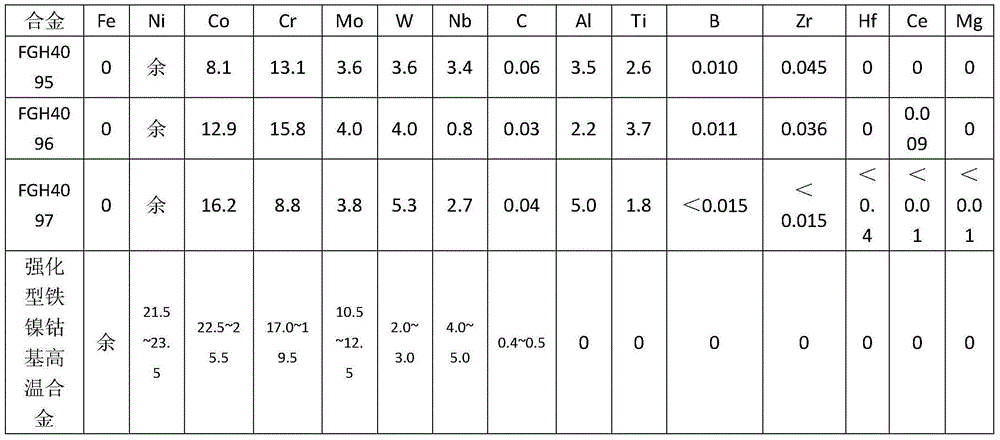

[0023] 1) In terms of mass fraction, pure element powder with a purity ≥ 99.5% is used as a raw material, including 0.4% carbon, 17.0% chromium, 2.0% tungsten, 4.0% niobium, 21.5% nickel, 22.5% cobalt, 10.5% molybdenum, the balance being iron;

[0024] 2) Under an inert atmosphere, place the raw materials in the tank of a high-energy vibrating rod mill, and perform a rod milling process using a mechanical alloying process to obtain a pre-alloyed powder mixed with supersaturated nanocrystalline and amorphous;

[0025] 3) Place the pre-alloyed powder in a stainless steel sheath for vacuum sealing;

[0026] 4) After sealing and welding, place the stainless steel sheath in a hot-pressing sintering furnace (ZT-15-10Y series vacuum hot-pressing sintering furnace produced by Shanghai Chenhua Electric Furnace Co., Ltd.) for hot-pressing sintering. The sint...

Embodiment 2

[0029] A method for preparing a precipitation-strengthened iron-nickel-cobalt-based superalloy, comprising the following steps:

[0030] 1) In terms of mass fraction, pure element powder with a purity ≥ 99.5% is used as a raw material, including 0.5% carbon, 18.0% chromium, 2.3% tungsten, 4.5% niobium, 22% nickel, 24% cobalt, 11.5% molybdenum, the balance being iron;

[0031] 2) Under an inert atmosphere, place the raw materials in the tank of a high-energy vibrating rod mill, and perform rod milling using a mechanical alloying process to obtain supersaturated nanocrystalline and amorphous mixed pre-alloyed powders;

[0032] 3) Place the pre-alloyed powder in a stainless steel sheath for vacuum sealing;

[0033] 4) After sealing and welding, place the stainless steel sheath in a hot-press sintering furnace for hot-press sintering, the sintering temperature is 1060°C, and the sintering time is 120min; the sintering system is: pressurize no more than 3Mpa before 900°C, Pressur...

Embodiment 3

[0036] A method for preparing a precipitation-strengthened iron-nickel-cobalt-based superalloy, comprising the following steps:

[0037] 1) In terms of mass fraction, pure element powder with a purity ≥ 99.5% is used as a raw material, including 0.5% carbon, 19.50% chromium, 3.0% tungsten, 5.0% niobium, 23.5% nickel, 25.5% cobalt, 12.5% molybdenum, the balance being iron;

[0038] 2) Under an inert atmosphere, place the raw materials in the tank of a high-energy vibrating rod mill, and perform rod milling using a mechanical alloying process to obtain supersaturated nanocrystalline and amorphous mixed pre-alloyed powders;

[0039] 3) Place the pre-alloyed powder in a stainless steel sheath for vacuum sealing;

[0040] 4) After sealing and welding, place the stainless steel sheath in a hot-press sintering furnace for hot-press sintering, the sintering temperature is 1080°C, and the sintering time is 100min; the sintering system is: pressurize no more than 3Mpa before 900°C, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com