Heterogeneous fixed abrasive wire saw for multi-line cutting

A fixed abrasive, multi-wire cutting technology, applied in fine working devices, stone processing equipment, manufacturing tools, etc., can solve the problems of the failure of the abrasive consolidation layer, the easy removal of saw wire abrasive particles, etc. The effect of cracking, reducing the breakage rate and alleviating stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

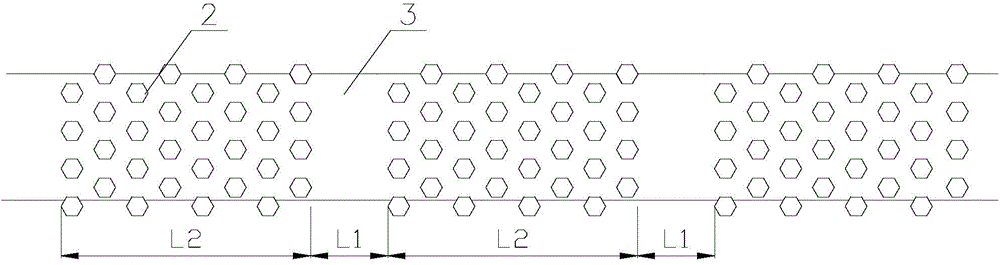

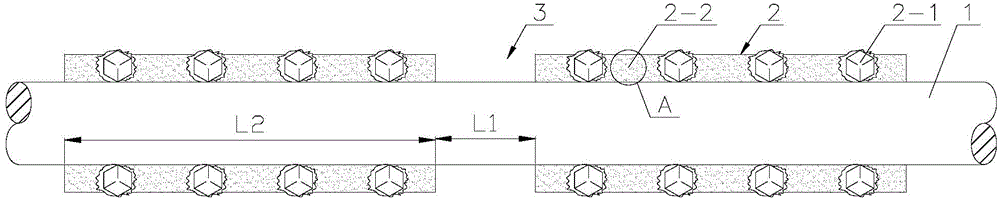

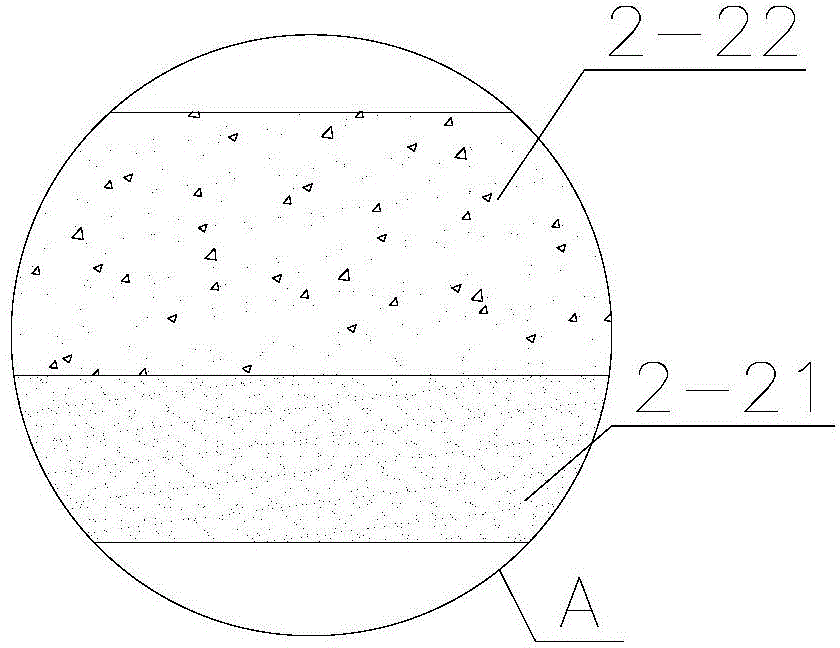

[0031] Such as figure 1 , figure 2As shown, a heterogeneous consolidated abrasive sawing wire for multi-wire cutting designed for a 350mm diameter guide wheel. The surface of the bus bar 1 is regularly and intermittently covered with an abrasive consolidation layer 2 for fixing the cutting abrasive 2-1. The shape of the abrasive consolidation layer 2 is approximately annular around the axis of the saw wire. The abrasive consolidation layer 2 For metal plating and alloy layers. The busbar 1 is a brass-plated wire with a diameter of 105 μm, and the cutting abrasive 2-1 uses diamond sand with an average particle size of 12 μm.

[0032] The part that does not cover the abrasive consolidation layer 2 is the stress relief gap 3, and the stress relief gap 3 is only composed of the busbar 1; the length L1 of each stress relief gap 3 is equal to 2mm; each abrasive consolidation layer 2 The length L2 is equal to 20mm. The length L1 of the stress relief gap 3 and the length L2 of th...

Embodiment 2

[0046] Such as Figure 4 As shown, this embodiment is basically the same as Embodiment 1, except that it is designed for a guide wheel with a diameter of 100 mm. The stress release gap 3 is composed of the busbar 1 and the electroplating layer 3-1 on the surface of the busbar 1. The electroplating layer is a Young's modulus much smaller than that of the abrasive consolidation layer 2. The length L1 of each stress relief gap 3 is equal to 0.7 mm; the length L2 of each abrasive consolidation layer 2 is equal to 22 mm.

[0047] The preparation method of this example is based on the method of Example 1, adding a step of electroplating the additional electroplating layer 3-1 after step (c).

Embodiment 3

[0049] Such as Figure 5 As shown, this embodiment is basically the same as Embodiment 1, the difference lies in that the shape of the abrasive consolidation layer 2 is a spiral around the axis of the saw wire. The length L1 of each stress relief gap is equal to 1.5 mm; the length L2 of each abrasive consolidation layer is equal to 35 mm. Both the length L1 of the stress release gap and the length L2 of the abrasive consolidation layer are along the axis of the generatrix.

[0050] Correspondingly, in the heterogeneous consolidated abrasive saw wire manufacturing equipment, the busbar pretreatment device sprays a spiral insulating tape 5 on the surface of the busbar 1 passing through it, such as Figure 8 As shown, the nozzle 4 can rotate around the busbar 1 in a circumferential direction, and the busbar 1 passes through at a constant speed to form a spiral insulating belt 5 on the surface.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com