Method for reducing cost of producing copper rod via continuous casting and continuous rolling

A technology of continuous casting, continuous rolling, and copper rods, applied in metal rolling, metal rolling, workpiece surface treatment equipment, etc. Production cost, effect of rational utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for continuous casting and rolling to reduce costs for producing copper rods, which is based on the existing technology, and the following processes in the prior art are modified:

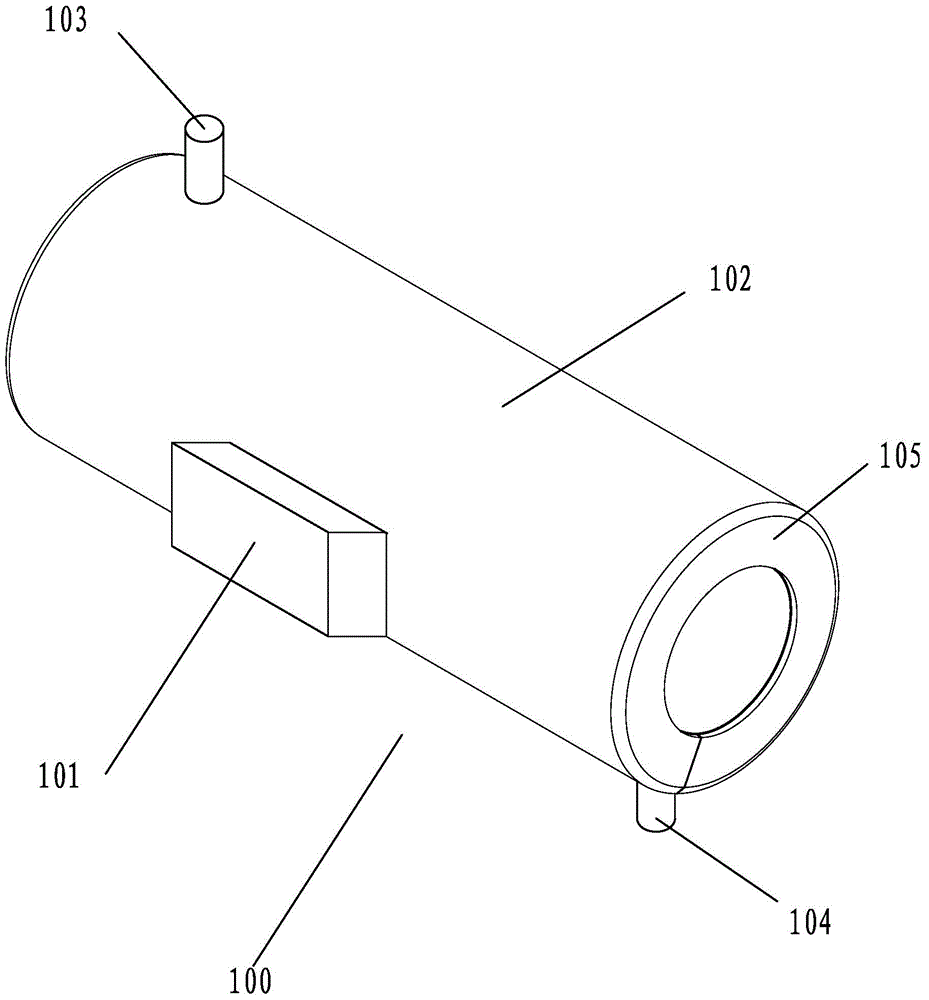

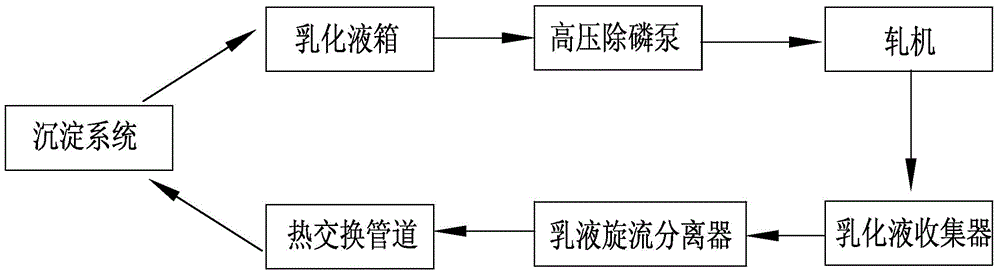

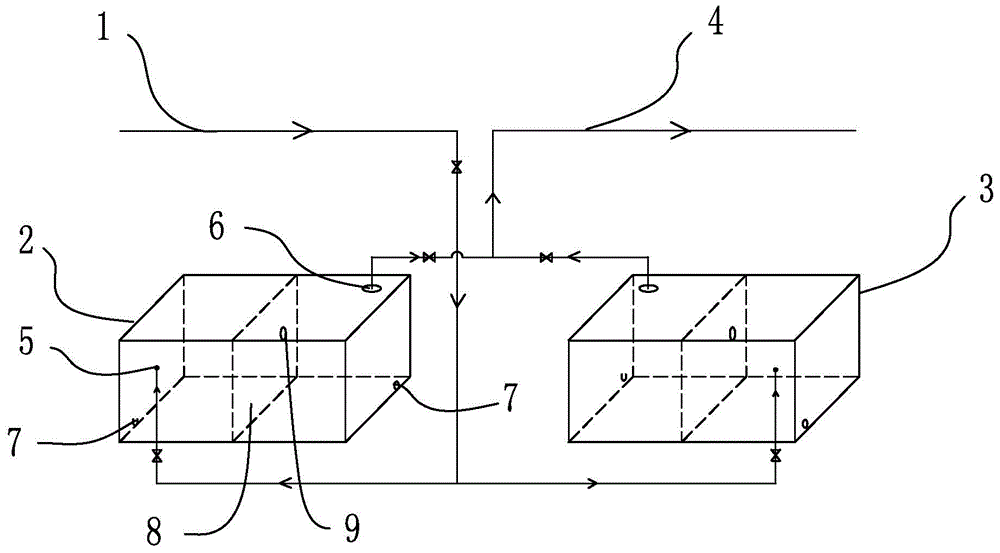

[0026] a. Smelting: The electrolytic copper raw material becomes copper liquid after smelting, and the copper liquid flows from the shaft furnace through the up launder into the holding furnace, and then flows into the tundish through the down launder to prepare for casting. Silicon carbide semicircular flow tubes, such as Figure 4 As shown, a metal support plate 200 is supported under the silicon carbide semicircular flow tube 201 , and the cross section of the metal support plate is arc-shaped with the arc facing upward. During the smelting process, the compressed air enters the down launder through the aeration pipe arranged on the down launder, such as figure 1 As shown, a water circulation heat exchange device 100 is added to the oxygen increase pipe to preheat the compressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com