Rolling brushing type gas dust-removing purification device

A gas dust removal and purification device technology, applied in chemical instruments and methods, the use of liquid separation agents, dispersed particle separation, etc., can solve the problems of increasing indoor particle concentration, noise, excessive humidification of indoor air, etc., and reduce the risk of influenza infection. Risk, efficient capture, small air resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

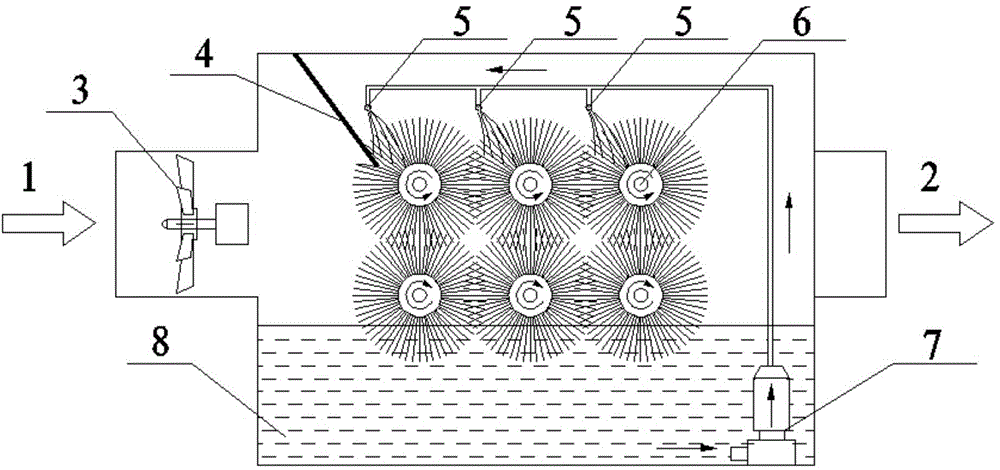

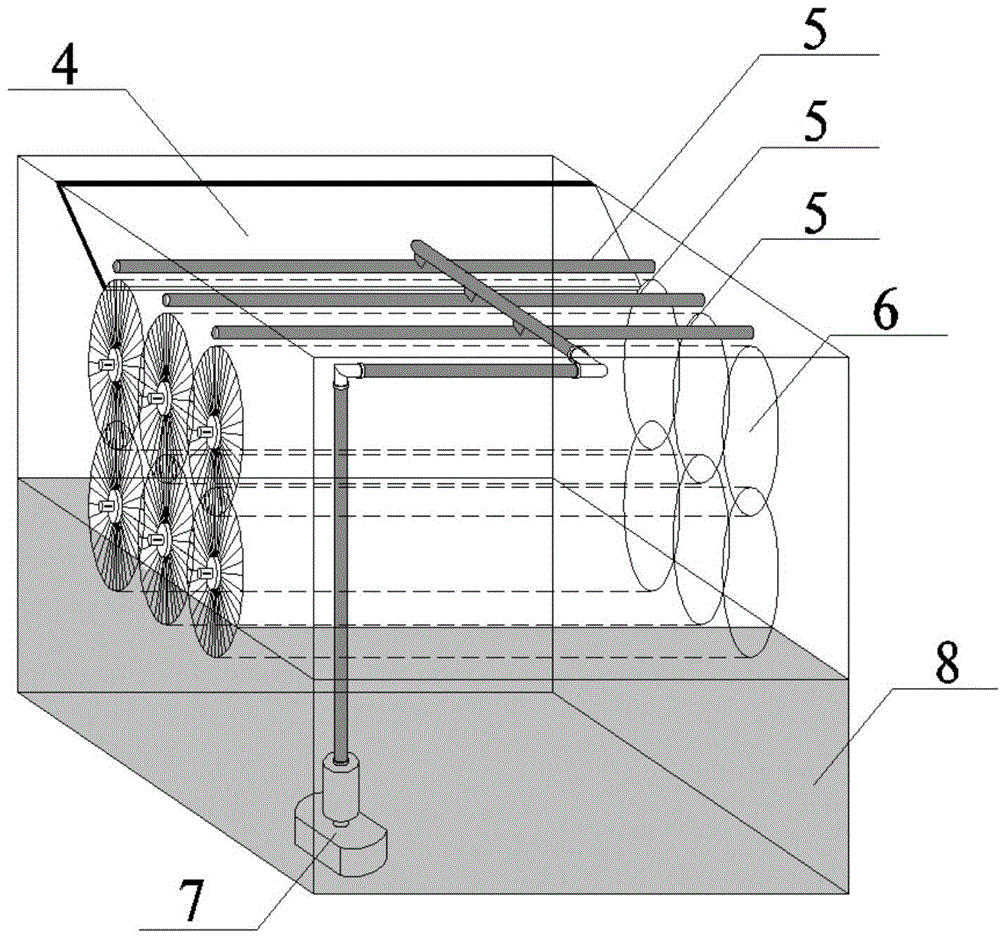

[0020] Take 6 brush rollers with a diameter of 30cm and a bristle length of 10cm, according to figure 1 The method shown is installed in a box. The two sides of the brush rollers are close to the box to avoid gas leakage. The upper 3 brush rollers rotate counterclockwise, while the lower 3 brush rollers rotate clockwise. The adjacent brushes The bristles of the rollers overlap each other to a depth of 2mm. Put 1% benzalkonium bromide aqueous solution into the water tank. The liquid level just submerges the lower bristles of the lower brush roller. The depth of the gas baffle inserted into the first brush roller on the upper layer is 2cm. After installing the intake fan, spray pump and spray pipe, the high-efficiency gas dust removal and purification device is obtained.

Embodiment 2

[0022] Take 4 brush rollers with a diameter of 5cm, and the length of the bristles is 2cm, according to figure 1 The method shown is installed in a box. The two sides of the brush rollers are close to the box to avoid gas leakage. The two brush rollers on the upper layer rotate counterclockwise, while the two brush rollers on the lower layer rotate clockwise. The adjacent brush rollers The bristles of the rollers overlap each other to a depth of 1 cm. Fill the water tank with 1% cetyltrimethylammonium bromide aqueous solution. The liquid level just submerges the lower bristles of the lower brush roller, and the gas baffle is inserted into the first bristle of the upper layer. The depth of the brush roller is 1cm, and the high-efficiency gas dust removal and purification device is obtained after installing an air intake fan, a spray pump and a spray pipe.

Embodiment 3

[0024] Take 8 brush rollers with a diameter of 20cm and a bristle length of 7cm, according to figure 1 The method shown is installed in a box. The two sides of the brush rollers are close to the box to avoid gas leakage. The 4 brush rollers on the upper layer rotate counterclockwise, while the 4 brush rollers on the lower layer rotate clockwise. The adjacent brush rollers The bristles of the rollers overlap each other to a depth of 1.4cm. Fill the water tank with 1% dibromohydantoin aqueous solution. The liquid level just submerges the lower bristles of the lower brush roller. The depth of the gas baffle inserted into the first brush roller on the upper layer is 3cm, the high-efficiency gas dust removal and purification device is obtained after installing the intake fan, spray pump and spray pipe.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com