Capsaicin particle preparing method

A technology of capsaicin and granules, which is applied in the field of food manufacturing, can solve the problems of less practical use and health hazards, and achieve the effects of convenient storage and transportation, adjustable spiciness, and uniform granules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

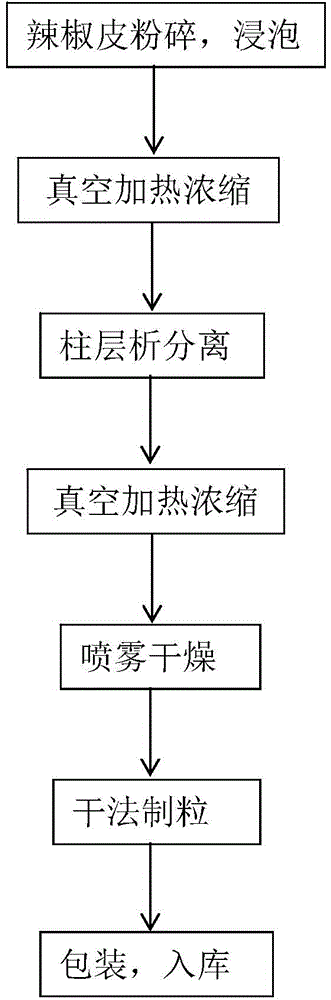

Method used

Image

Examples

Embodiment Construction

[0028] When buying peppers, in addition to prosecuting the spiciness, color value, hue, water content, and skin weight ratio, focus on prosecuting pesticide residues. After the capsicum peel is separated, the capsicum peel is pulverized by a pulverizer, and the pulverized powder is added into an organic solvent for soaking. The addition amount of the capsicum peel is 10 kg, and the addition amount of the organic solvent methanol is 100 kg. At room temperature, soak for 36 hours, and filter to obtain the crude extract.

[0029] Concentrate the crude extract by distillation under pressure, the vacuum degree is 0.02-0.05MPa, the concentration temperature is 35°C, and the concentration is stopped when no organic solvent is evaporated.

[0030] The column was packed by wet packing method, the filler was silica gel, the mesh number was 600 mesh, the packing solvent was the same as the eluent, ethyl acetate / methanol, and the volume ratio was 3:1.

[0031] After packing the column, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com