Automatic stereo planting vegetable soilless culture device

A soilless culture, auto-stereoscopic technology, applied in soilless culture, cultivation, agricultural gas emission reduction and other directions, can solve the problems of low land area utilization, pollution of vegetables and fruits, deterioration of soil nutrition, etc., and achieve good economic benefits and social benefits. Benefit, good product quality, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

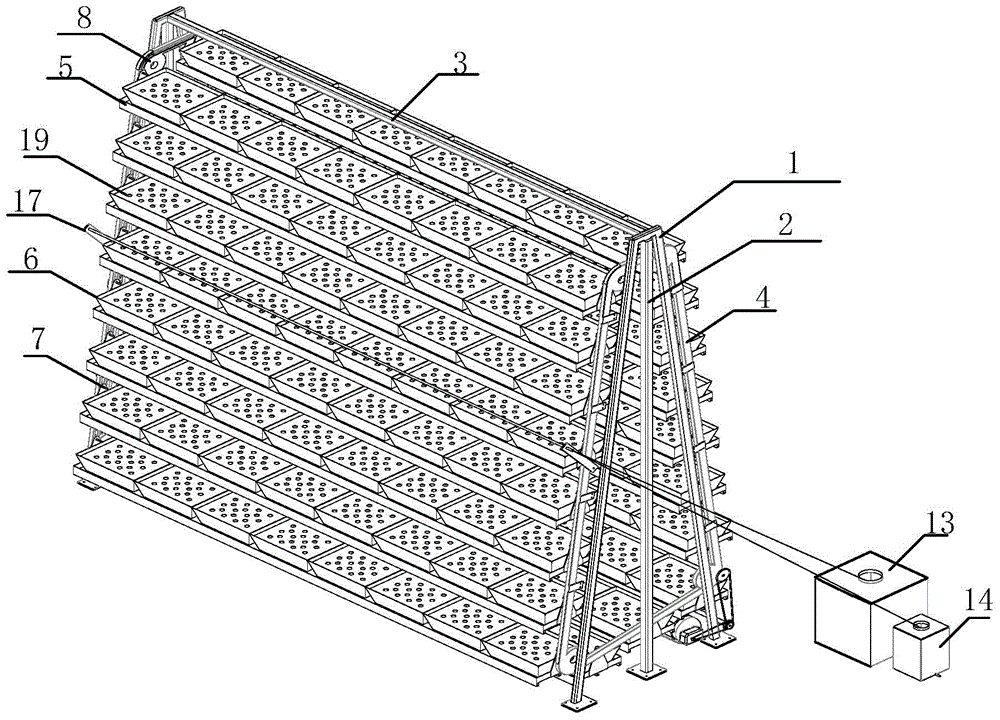

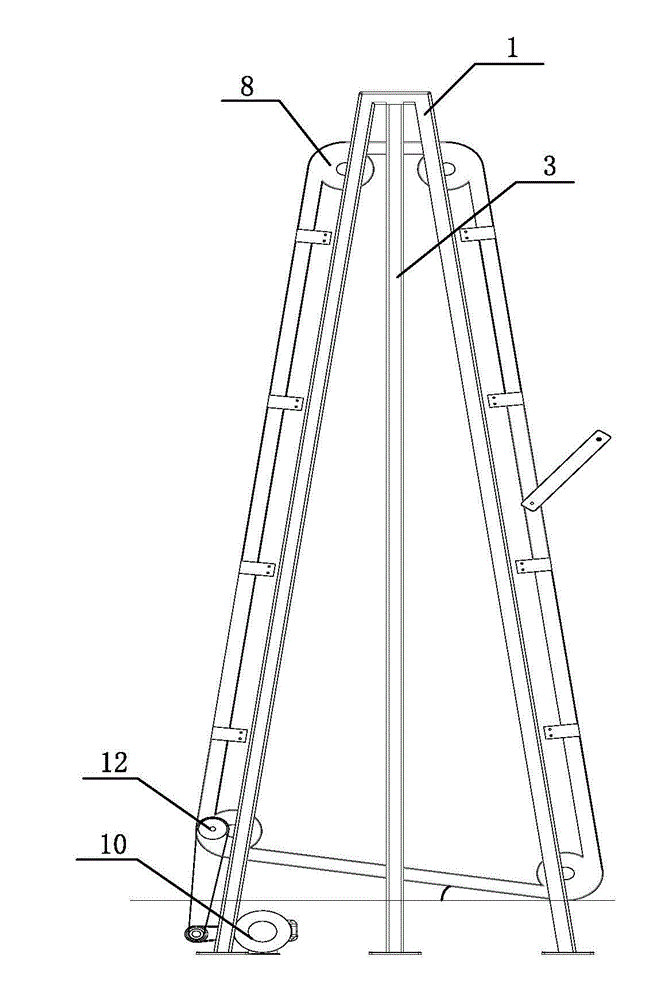

[0046] An automatic three-dimensional planting device for soilless cultivation of vegetables, such as figure 1 , figure 2 , image 3 As shown, it includes a bracket 1, an upper beam 2, a column 3, a track 4, a transmission assembly, more than two trays 5 and a planting box 6;

[0047] The support 1 is connected to the ground and forms an isosceles trapezoid with the ground. The top rod of the support 1 is the upper bottom of the isosceles trapezoid, and the ground part is the lower bottom of the isosceles trapezoid, and the length of the upper bottom is less than that of the lower bottom. length;

[0048] The upper beam 2 is located between the two supports 1, and the two ends are respectively fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com