Ultrahigh-strength high-toughness high corrosion-resisting CuNiSiNbSn elastic copper alloy and preparation method thereof

An elastic copper alloy, high corrosion resistance technology, applied in CuNiSiNbSn elastic copper alloy and its preparation, ultra-high strength, high toughness and high corrosion resistance CuNiSiNbSn elastic copper alloy and its preparation field, can solve the lack of industrialized preparation process, restrict electrical appliances Industrial development, low alloy elongation and other problems, to achieve the effect of good corrosion resistance, high strength and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

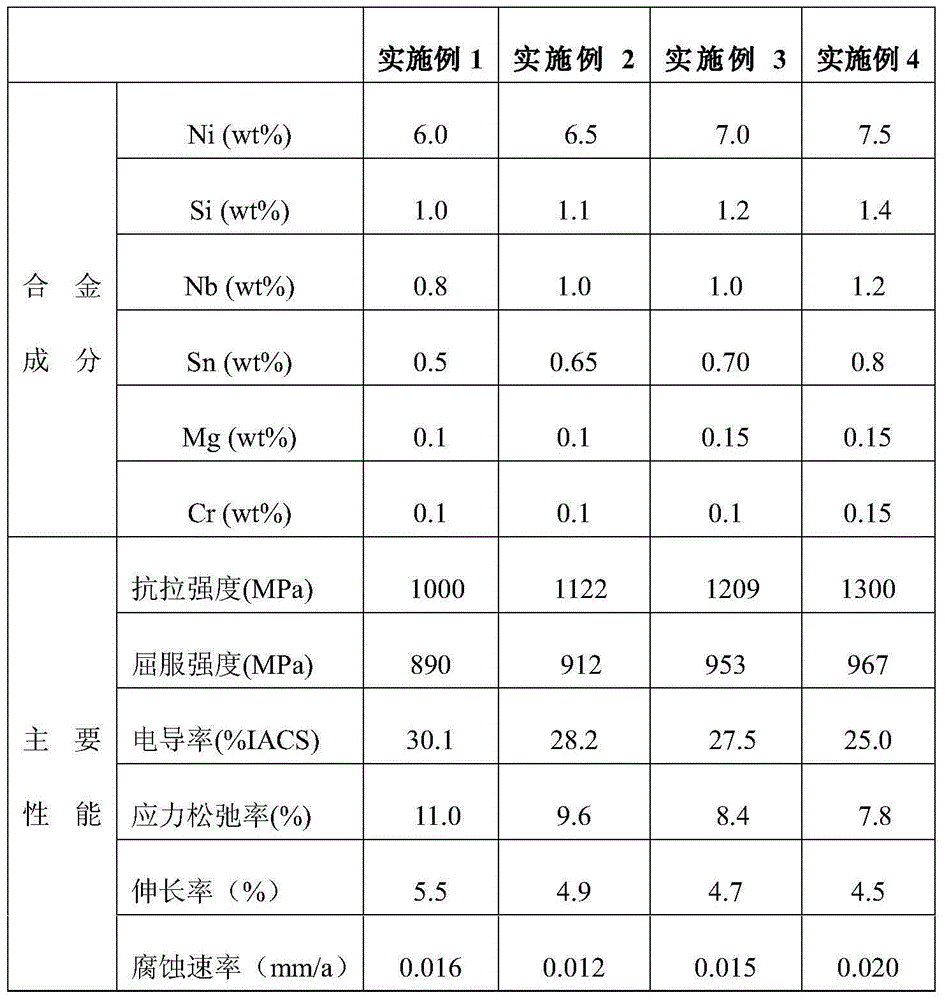

[0064] According to the components corresponding to Example 1 in Table 1, the preparation is carried out according to the process flow described in Example 1, and the condition parameters during the preparation process are shown in Table 1 corresponding to the condition parameters of Example 1;

[0065] The specific operation process is as follows:

[0066] Step 1 smelting and casting

[0067] According to the designed alloy group distribution, electrolytic copper, electrolytic nickel (nickel source), elemental silicon (silicon source), elemental niobium (niobium source), electrolytic tin (tin source), copper-magnesium intermediate alloy (magnesium source), copper- After the chromium master alloy (chromium source), the prepared electrolytic copper is first added to the intermediate frequency induction melting furnace, and the temperature is raised to 1300-1320 ℃, and then the prepared electrolytic nickel, elemental silicon, elemental niobium, electrolytic tin, and copper are added- ...

Embodiment 2

[0087] According to the components corresponding to Example 2 in Table 1, the preparation is carried out according to the process flow described in Example 2, and the condition parameters in the preparation process are shown in the corresponding condition parameters of Example 2 in Table 1.

[0088] The specific operation process is as follows:

[0089] Step 1 smelting and casting

[0090] According to the designed alloy group distribution, electrolytic copper, electrolytic nickel (nickel source), elemental silicon (silicon source), elemental niobium (niobium source), electrolytic tin (tin source), copper-magnesium intermediate alloy (magnesium source), copper- After the chromium master alloy (chromium source), the prepared electrolytic copper is first added to the intermediate frequency induction melting furnace, and the temperature is raised to 1300-1320 ℃, and then the prepared electrolytic nickel, elemental silicon, elemental niobium, electrolytic tin, and copper are added- Chro...

Embodiment 3

[0110] According to the components corresponding to Example 3 in Table 1, the preparation is carried out according to the process flow described in Example 3. The condition parameters in the preparation process are shown in the corresponding condition parameters of Example 3 in Table 1.

[0111] The specific operation process is as follows:

[0112] Step 1 smelting and casting

[0113] According to the designed alloy group distribution, electrolytic copper, electrolytic nickel (nickel source), elemental silicon (silicon source), elemental niobium (niobium source), electrolytic tin (tin source), copper-magnesium intermediate alloy (magnesium source), copper- After the chromium master alloy (chromium source), the prepared electrolytic copper is added to the intermediate frequency induction melting furnace, and the temperature is increased to 1310-1330°C, and then the prepared electrolytic nickel, elemental silicon, elemental niobium, electrolytic tin, and copper are added- Chromium ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com