A kind of production recipe method of polishing wheel

A polishing wheel and weight ratio technology, which is applied in the field of grinding wheels and stone polishing wheels, can solve the problems of poor mechanical properties and shape retention of resin grinding wheels, reduce the service life of grinding wheels, and affect the surface quality of processed workpieces, etc., to achieve self-sharpening Good performance, high hardness and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] According to the preparation method of polishing wheel of the present invention, it comprises the following steps:

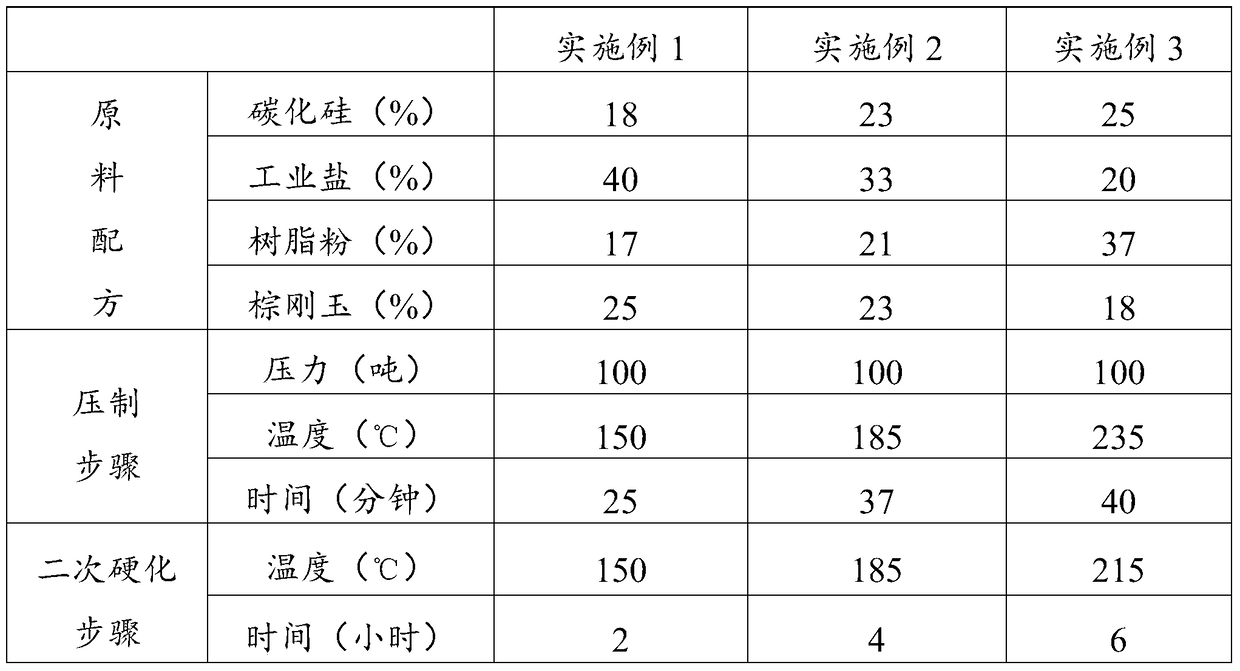

[0032] First enter the mixing step S1100, prepare the materials, and mix the raw materials in the following weight ratio evenly to obtain the mixture: 18%-25% of silicon carbide, 20%-40% of industrial salt, 15%-25% of resin powder, 18% of brown corundum %~25%. The mixed raw materials should have good plasticity and fluidity, and the materials should not be agglomerated, let alone have powder balls, so as to ensure sufficient injection molding. Through this step, the mixture is obtained.

[0033] Then enter the pressing step S1200, which is also called a hardening step. The specific operation is: install the mold, weigh the required amount of mixture and add it into the cavity of the mold, and then press after scraping. Those who need to place reinforced glass fiber mesh should be placed as required. Then it is heated to 150-235° C. and screened by the ...

Embodiment 1-3

[0041] According to the formula in the above table 1 and the process parameters of each operation step, accurately weigh various materials respectively, and make the polishing wheel according to the following steps:

[0042] Mixing step S1100, uniformly mixing the raw materials according to the formula to obtain a mixed material;

[0043] Pressing step S1200, putting the mixed material into the mold and hot pressing to form the blank;

[0044] Secondary hardening step S1300, after demolding the blank, put it into an oven to heat and solidify to obtain a blank;

[0045] Finished product step S1400, the rough embryo passes the quality inspection to obtain the finished product.

[0046] After the polishing wheel made by the above-mentioned embodiment was used in many stone processing factories, the polishing wheel had high hardness, good grinding performance, high mechanical strength and long service life, which obviously improved the grinding of the workpiece by the polishing w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com