Alloy ultrasonic-spraying strengthening method for roll pass surface of finishing roll of section steel and spraying material

A technology of supersonic spraying and surface alloying, which is applied in the direction of metal material coating process, coating, molten spraying, etc., can solve the problems of accelerated roll hole wear, high equipment precision requirements, and different thickness of alloy layer, etc., to achieve roll Effects of extended online time, improved steel quality, and extended roll life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1 The method of supersonic spraying strengthening method for the surface alloy of the finishing roll pass of section steel, the specific process is:

[0015] 1) Surface pretreatment a. When there is a fatigue layer on the surface and severely strained groove marks on the surface, it can be turned if the strength permits to provide space for thermal spraying; b. Remove oil, rust and paint on the surface of the workpiece To make the surface of the workpiece clean, the oily paint can be removed with a solvent cleaning agent. If the oil has penetrated into the matrix material, it can be removed by flame heating. The rust layer can be removed by acid leaching, mechanical polishing or sandblasting; c. Turning, Grinding or matching method to remove the wear layer on the surface of the roll, so that the surface roughness of the roll substrate is controlled between RA0.3 and RA3.0, and then sandblasted;

[0016] 2) Spraying a. Using conventional spraying equipment, choose ...

Embodiment 2

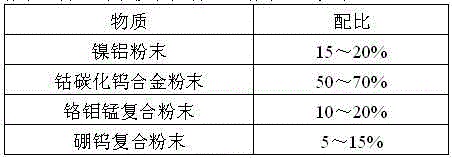

[0019] Example 2 The treatment was carried out in the same manner as in Example 1. The spraying material composition ratio is shown in Table 1, and the performance of the sprayed roll was tested. The specific data is shown in Table 2 below.

Embodiment 3

[0020] Example 3 The treatment was carried out in the same manner as in Example 1. The spraying material composition ratio is shown in Table 1, and the performance test of the sprayed roll is performed. The specific data is shown in Table 2 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com