Vanadium-phosphorus oxide catalyst for preparing maleic anhydride through cyclohexane oxidation, and preparation method thereof

A vanadium phosphorus oxide and catalyst technology, which is applied in physical/chemical process catalysts, chemical instruments and methods, organic chemistry, etc., to achieve uniform distribution of active centers, good reactivity, and good maleic anhydride selectivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] (2) Preparation of vanadium phosphorus oxygen catalyst

[0051] Step (1) The obtained vanadium phosphorus oxide is first formed to obtain a vanadium phosphorus oxygen catalyst intermediate, and then activated; or the obtained vanadium phosphorus oxide is first activated to obtain a vanadium phosphorus oxygen catalyst intermediate, and then formed to obtain vanadium phosphorus oxygen catalyst.

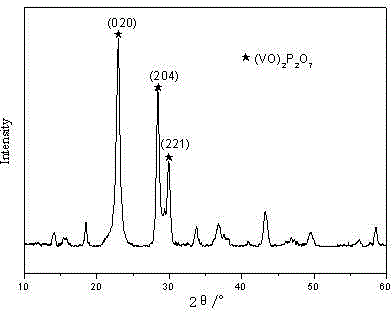

[0052] The shape of the obtained vanadium-phosphorus-oxygen catalyst can be shapes such as pressed sheet, sphere, extruded bar, and the phase of matter of the catalyst is mainly super vanadyl phosphate ((VO 2 ) 2 P 2 o 7 )Mutually.

[0053] The above-mentioned molding process generally includes: adding vanadium phosphorus oxide powder (or activated vanadium phosphorus catalyst intermediate) to graphite powder with a mass fraction of 3% to 5%, after mixing thoroughly, using a rotary tablet press, Properly adjust the impact strength, extrude into a certain shape, such as colum...

Embodiment 1

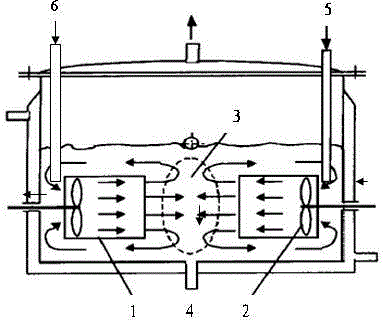

[0060] exist figure 1 In the impingement flow reactor shown, add 500 mL of isoamyl alcohol, start the impingement flow reactor, and make the rotation speed of the stirring blade reach 1500 r / min, and the reaction liquid passes through the guide tube to form an impingement flow. Raise the reaction temperature and keep it at 130±2°C, beat 29.53g of vanadium pentoxide and 149mL of isoamyl alcohol in a FSH-2 high-speed homogenizer to form a suspension, and make 44.7g of phosphoric acid with a concentration of 85% and the above The suspension was added into the reactor from two inlets of the impinging flow reactor at a certain flow acceleration rate, and the reaction time was maintained for 6 hours to complete the reaction. After the reaction solution was cooled to room temperature, it was vacuum filtered, and the filter cake was rinsed three times with a small amount of isobutanol, and then the filter cake was placed in an enamel tray and dried naturally at room temperature, dried...

Embodiment 2

[0064] exist figure 1 In the impingement flow reactor shown, add 500 mL of isoamyl alcohol, 0.3 g of ferric nitrate hexahydrate, and 0.5 g of zirconium nitrate. The deflector creates impingement flow. Raise the reaction temperature and keep it at 135±2°C, beat 29.53g of vanadium pentoxide and 149mL of isoamyl alcohol in a FSH-2 high-speed homogenizer to form a suspension, and make 34.98g of phosphoric acid with a concentration of 100% and the above The suspension was added into the reactor from two inlets of the impinging flow reactor at a certain flow acceleration rate, and the reaction time was maintained for 8 hours to complete the reaction. After the reaction solution was cooled to room temperature, it was vacuum filtered, and the filter cake was rinsed with a small amount of isoamyl alcohol three times, then the filter cake was placed in an enamel dish and dried naturally at room temperature, dried in an oven at 100°C for 10 hours, and finally dried in a muffle furnace. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com