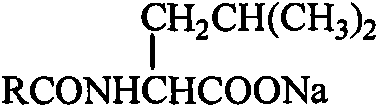

Method for preparing grease acyl sodium leucine and surface active agent composition containing grease acyl sodium leucine in phase-transfer catalysis way

A technology of sodium oleoyl leucine and sodium cocoyl leucine, which is applied in the field of fine chemicals, can solve problems such as poor solubility, and achieve the effects of less reaction steps, high content of active substances, and excellent product performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

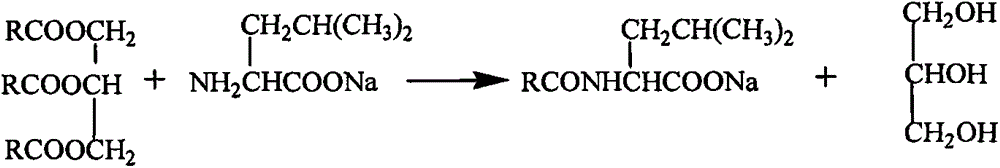

Method used

Image

Examples

Embodiment 1

[0024] Add 0.1mol coconut oil and 36.0g PEG800 into a reaction flask equipped with stirring, thermometer, water separator, and reflux condenser, heat up to 100°C and stir to melt, then add 0.3mol sodium leucine, heat to 160°C, and react at a constant temperature After 12 hours, the content of sodium capryl leucine was 1.5%, the content of sodium capryl leucine was 2.0%, the content of sodium lauroyl leucine was 31.8%, the content of sodium myristoyl leucine was 12.6%, and the content of sodium palmitoyl leucine was 12.6%. Sodium 7.0%, Sodium Linoleoyl Leucine 1.5%, Sodium Oleoyl Leucine 11.4%, Sodium Stearoyl Leucine 1.5%, Sodium Leucine 0.5%, Sodium Fatty Acid 0.9% , PEG800 content of 23.4%, glycerin content of 5.9% cocoyl leucine sodium surfactant composition.

Embodiment 2

[0026] Add 0.1mol olive oil and 36.0g PEG800 into a reaction flask equipped with stirring, thermometer, water separator, and reflux condenser, heat up to 100°C and stir to melt, then add 0.3mol sodium leucine, heat to 160°C, and react at a constant temperature After 8 hours, the content of sodium palmitoyl leucine was 7.6%, the content of sodium palmitoleyl leucine was 0.5%, the content of sodium oleoyl leucine was 61.2%, the content of sodium stearoyl leucine was 2.5%, and the content of arachidyl leucine was 2.5%. Sodium olive oil acyl leucine surfactant composition with 0.2% sodium acid content, 0.6% sodium leucine content, 1.1% fatty acid sodium content, 21.1% PEG800 content and 5.2% glycerin content.

Embodiment 3

[0028] Add 0.1mol hydrogenated tallow and 36.0g PEG800 into the reaction flask equipped with stirring, thermometer, water separator and reflux condenser, heat up to 100°C and stir to melt, then add 0.3mol sodium leucine, heat to 160°C, constant Temperature reaction for 12 hours to obtain 0.2% sodium myristoyl leucine content, 2.2% sodium myristoyl leucine content, 0.7% sodium pentadecanoyl leucine content, and 1.6% palm oilyl leucine sodium content. %, sodium palmitoyl leucine content 20.1%, sodium heptadecenyl leucine content 0.3%, sodium heptadecenyl leucine content 1.4%, sodium linoleoyl leucine content 1.9%, oleoyl Hydrogenated tallowyl leucine with 25.7% sodium leucine content, 18.1% sodium stearyl leucine content, 0.6% sodium leucine content, 1.2% fatty acid sodium content, 20.9% PEG800 content, and 5.1% glycerin content Sodium Acid Surfactant Composition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com