High-strength magnesium jade porcelain and manufacturing method thereof

A manufacturing method and technology of magnesia jade porcelain, applied in the field of ceramics, can solve the problems of failure to be popularized in industrialization, unsustainable production, tight supply of bone carbon, etc., and achieve excellent product performance, good whiteness, high quality and low price of resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

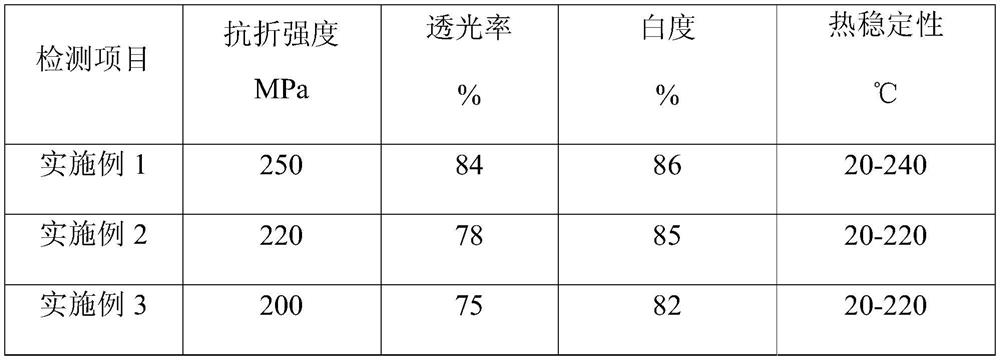

Examples

Embodiment 1

[0030] A kind of high-strength magnesia jade porcelain, the blank of magnesia jade porcelain is composed of the following raw materials in weight ratio: 40 parts of black talc modified washing mud, 40 parts of black talc calcined material, 15 parts of kaolin and 5 parts of lithium china stone;

[0031] A special glaze for lead-free frit consists of chemical composition: SiO2: 56.3%, Al2O3: 9.1%, Fe2O3≦0.01%, TiO2≦0.03%, CaO: 9%, MgO: 3.5%, ZnO: 6%, BaO: 4.3%, K2O: 4%:, Na2O: 1.2%, Li2O: 0.7%, SrO: 1.2%, B2O3: 4%, loss of ignition≦0.1%.

[0032] The above-mentioned manufacturing method of high-strength magnesia jade porcelain comprises the following steps:

[0033] Step 1: Add 0.1% of calcium ion organic complex EDTA to Guangfeng black talc for grinding, sieve through a 250-325 mesh screen, remove quartz, unweathered carbonate minerals and other impurities, and pass through the machine , homogenization, magnetic separation, and then dehydration treatment to obtain black talc m...

Embodiment 2

[0041] A kind of high-strength magnesia jade porcelain. The blank of magnesia jade porcelain is composed of raw materials in the following weight ratio: 30 parts of black talc modified washing mud, 40 parts of black talc calcined material, 20 parts of kaolin and 10 parts of lithium china stone;

[0042] A special glaze for lead-free frit consists of chemical composition: SiO2: 56.3%, Al2O3: 9.1%, Fe2O3≤0.01%, TiO2≤0.03%, CaO: 9%, MgO: 3.5%, ZnO: 6%, BaO: 4.3%, K2O: 4%:, Na2O: 1.2%, Li2O: 0.7%, SrO: 1.2%, B2O3: 4%, loss of ignition ≤ 0.1%.

[0043] The above-mentioned manufacturing method of high-strength magnesia jade porcelain comprises the following steps:

[0044]Step 1: Add 0.2% calcium ion organic complex EDTA to Guangfeng black talc for grinding, sieve through a 250-325 mesh screen, remove quartz, unweathered carbonate minerals and other impurities, and pass through the machine , homogenization, magnetic separation, and then dehydration treatment to obtain black talc mo...

Embodiment 3

[0052] A kind of high-strength magnesia jade porcelain. The blank of magnesia jade porcelain is composed of raw materials in the following weight ratio: 50 parts of black talc modified washing mud, 30 parts of black talc calcined material, 10 parts of kaolin and 10 parts of lithium china stone;

[0053] A special glaze for lead-free frit consists of chemical composition: SiO2: 56.3%, Al2O3: 9.1%, Fe2O3≤0.01%, TiO2≤0.03%, CaO: 9%, MgO: 3.5%, ZnO: 6%, BaO: 4.3%, K2O: 4%:, Na2O: 1.2%, Li2O: 0.7%, SrO: 1.2%, B2O3: 4%, loss of ignition ≤ 0.1%.

[0054] The above-mentioned manufacturing method of high-strength magnesia jade porcelain comprises the following steps:

[0055] Step 1: Add 0.15% calcium ion organic complex EDTA to Guangfeng black talc for grinding, and then sieve through a 250-325 mesh sieve to remove quartz, unweathered carbonate minerals and other impurities, and pass through the machine , homogenization, magnetic separation, and then dehydration treatment to obtain b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com