High-power laser for 808nm ceiling light field

A technology of high-power lasers and flat top light, which is applied to lasers, laser components, semiconductor lasers, etc., can solve problems such as high working voltage, low electro-optical conversion efficiency, and change the reliability of lasers, so as to reduce voltage drop and improve Optical damage threshold, effect of increasing near-field spot size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

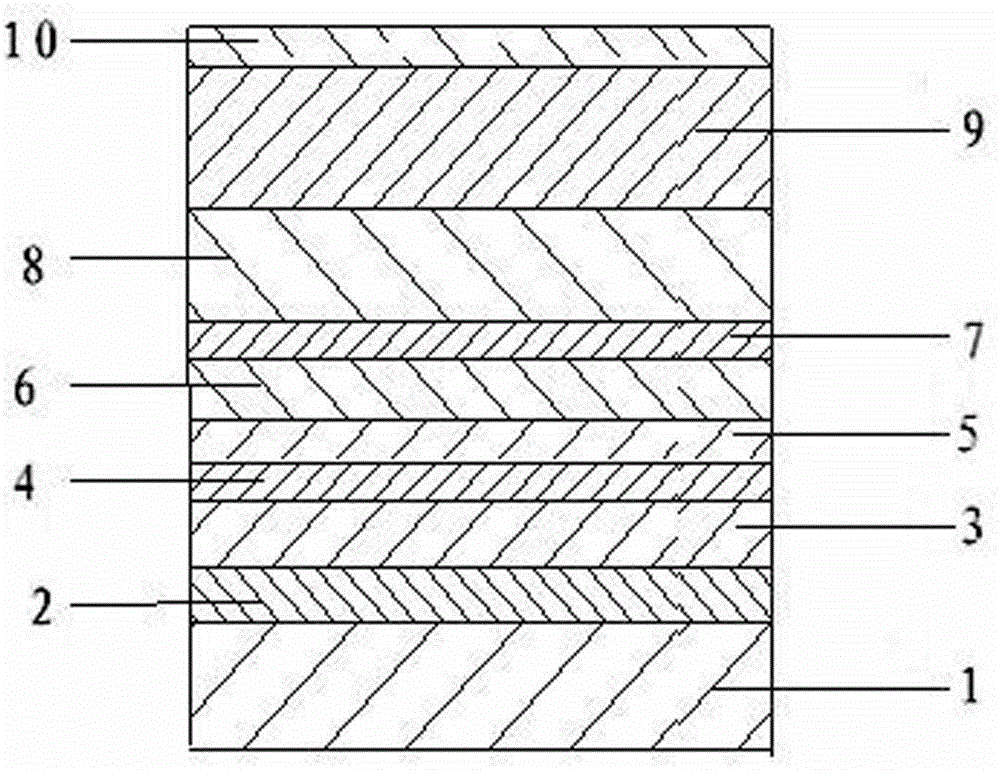

[0021] Such as figure 1 As shown, the 808nm flat-top optical field high-power laser includes a substrate 1, a buffer layer 2, a lower confinement layer 3, a lower optical field effect layer 4, a lower waveguide layer 5, a quantum well layer 6, an upper waveguide layer 7, and an upper optical layer. Field effect layer 8 , upper confinement layer 9 and electrode contact layer 10 .

[0022] The substrate 1 is used for the epitaxial growth of each layer of semiconductor laser materials. In the present invention, the substrate 1 is N-type gallium arsenide on the (100) plane, which can facilitate the injection of electrons and reduce the material of the substrate 1. of series resistance.

[0023] The buffer layer 2 is fabricated on the substrate 1 and is an N-type gallium arsenide material. Its purpose is to form a high-quality epitaxial surface, reduce the stress on the substrate 1 and other layers, and eliminate the defects of the substrate 1 to other layers. Propagation, in ord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Doping concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com