Polymer composite material solid electrolyte and preparation method thereof

A solid electrolyte and composite material technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of large quantities, low ionic conductivity and mechanical properties, and achieve lower production costs, superior performance, and reduced crystallization ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

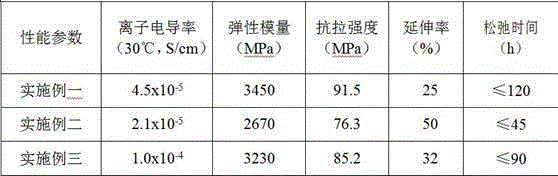

Examples

Embodiment 1

[0029] In this example, the preparation method of the polymer composite solid electrolyte is based on the aqueous solution casting method, and the steps are as follows:

[0030] a. Pour 600 parts of cold water into the reaction kettle, start the mixer, add 60 parts of polyvinyl alcohol with an alcoholysis degree of 88%, slowly raise the temperature to 90°C, and mix mechanically for 2 hours to obtain a uniform solution;

[0031] b. Cool down to 50°C, add 30 parts of lithium perchlorate, and stir for 2.5 hours to completely dissolve it in the aqueous solution of polyvinyl alcohol;

[0032] c. Continue to cool down to 40°C, slowly add 25 parts of an aqueous dispersion of silica nanoparticles (20% solid content), and mix for 3 hours under the joint action of ultrasonic waves and mechanical stirring;

[0033] d. Add 5 parts of water-dispersible polymeric isocyanate dropwise and stir for 15-30 minutes;

[0034] e. The above solution was poured into a polytetrafluoroethylene co...

Embodiment 2

[0037] This embodiment is basically the same as Embodiment 1, especially in that:

[0038] In this embodiment, the preparation method of polymer composite solid electrolyte, the steps are as follows:

[0039] a. Pour 600 parts of cold water into the reaction kettle, start the mixer, add 55 parts of polyvinyl acetate-ethylene emulsion (VAE) rubber powder, slowly raise the temperature to 60°C, and mix mechanically for 2 hours to obtain a uniform solution;

[0040] b. Cool down to 50°C, add 35 parts of lithium carbonate, and stir for 3 hours to completely dissolve in the VAE solution;

[0041] c. Continue to cool down to 30-40°C, slowly add 30 parts of nano-calcium carbonate aqueous dispersion (with a solid content of 20%), and mix for 2.5 hours under the joint action of ultrasonic waves and mechanical stirring;

[0042] d. Add 4 parts of water-dispersible polymeric polyisocyanate dropwise and stir for 15-30 minutes;

[0043] e. This step is identical with embodiment one; ...

Embodiment 3

[0046] This embodiment is basically the same as the previous embodiment, and the special features are:

[0047] In this embodiment, the preparation method of polymer composite solid electrolyte, the steps are as follows:

[0048] a. Pour 600 parts of cold water into the reaction kettle, start the mixer, add 50 parts of polyvinyl alcohol with an alcoholysis degree of 99% and 10 parts of carboxymethyl cellulose, slowly raise the temperature to 95°C, and mix mechanically for 2 hours to obtain a uniform solution;

[0049] b. Cool down to 50°C, add 30 parts of lithium sulfate, and stir for 2.5 hours to completely dissolve in the mixed aqueous solution of polyvinyl alcohol and carboxymethyl cellulose;

[0050] c. Continue to cool down to 30-40°C, slowly add 20 parts of nano-titanium dioxide aqueous dispersion (with a solid content of 20%), and mix for 3 hours under the joint action of ultrasonic waves and mechanical stirring;

[0051] d. Add 6 parts of high-functionality polyis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com