Heat exchange fins and membrane heat exchange plates for heat exchangers

A technology of heat exchange fins and heat exchangers, applied in heat exchange equipment, lighting and heating equipment, tubular elements, etc., can solve problems affecting the reliability and economy of pot protection equipment, low-temperature corrosion of the heating surface at the tail, etc., to achieve Avoid direct scouring of flue gas, improve heat transfer performance, and improve the strengthening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

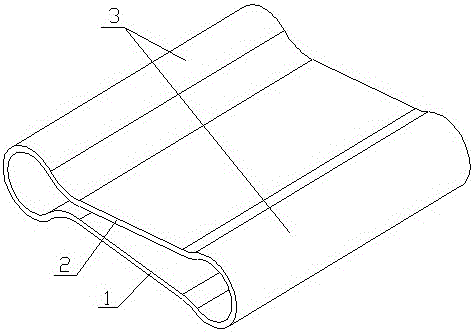

[0018] Such as figure 1 As shown, the heat exchange fin used in the heat exchanger of the present invention includes a bottom plate 1, a top plate 2 and two round tubes 3, the two round tubes 3 are arranged in parallel and have long grooves along the axial direction, and the bottom plate 1 Arranged opposite to the top plate 2 and connected to the bottom edge and the top edge of the long grooves of the two round pipes 3 on both sides.

[0019] Further, the above-mentioned bottom plate 1 and top plate 2 are smoothly connected with the bottom edge and the top edge of the long grooves of the two round pipes 3 .

[0020] Further, the bottom plate 1 and the top plate 2 are arranged in parallel.

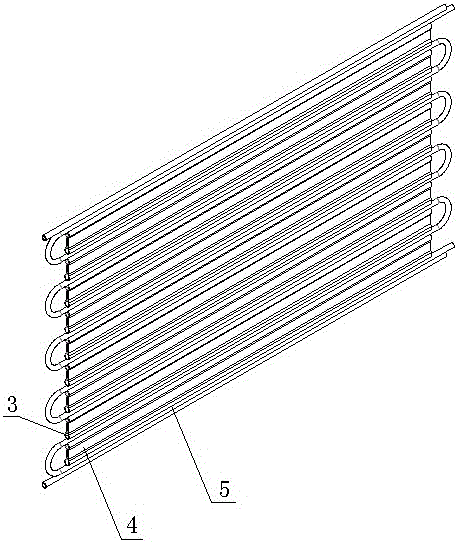

[0021] Such as figure 2 As shown, further, the bottom plate 1 and the top plate 2 are arranged in a figure-eight shape. The bottom plate and top plate arranged in a figure-eight shape are in the same direction as the flue gas, which is conducive to increasing the vortex flow of the flue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com