Stitched laminar flexible heat insulation material and preparation method thereof

A flexible thermal insulation material, layered technology, applied in the field of stitched layered flexible thermal insulation materials and its preparation, can solve the problem of no thermal protection stitched composite materials, to improve the volume fraction and interlayer shear performance, and inhibit the expansion , the effect of meeting the heat insulation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

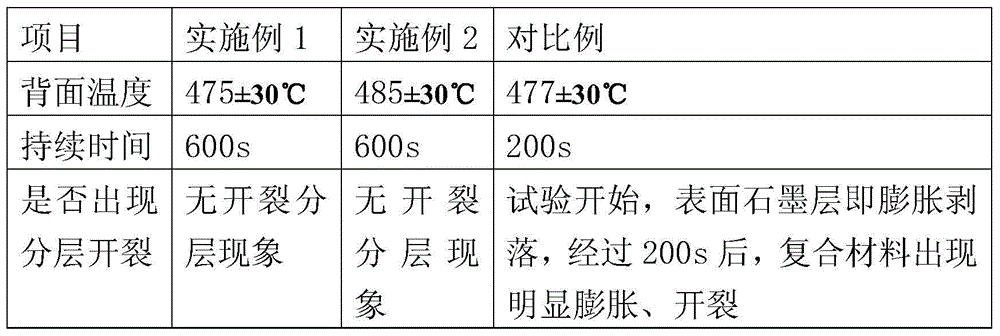

Embodiment 1

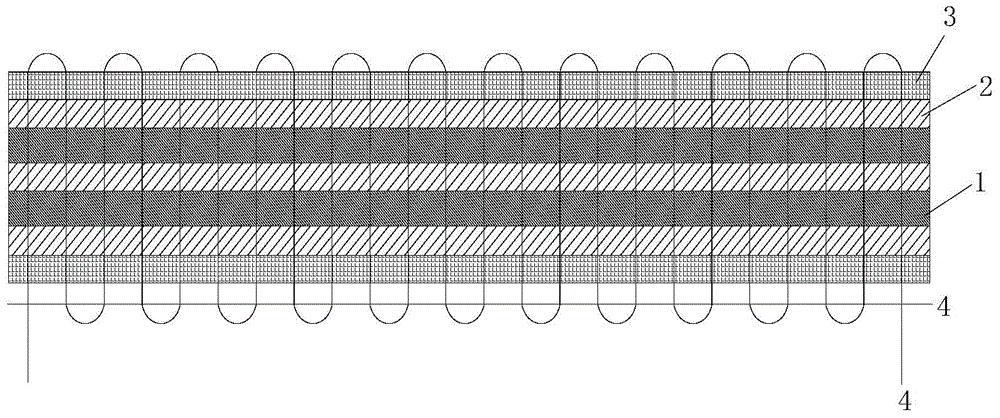

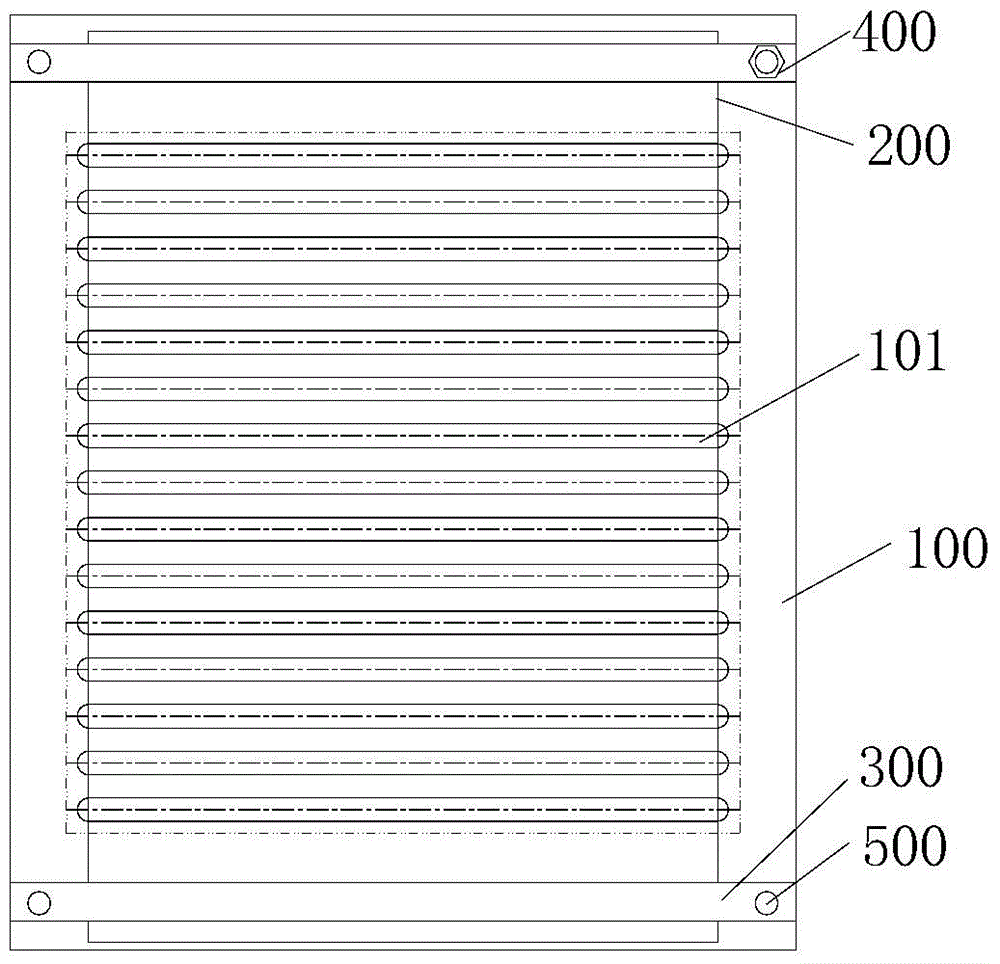

[0045] Mix 65g of alumina fiber with 4550g of deionized water, and use a high-speed stirrer to stir and mix at 400r / min for 5min to obtain alumina fiber slurry;

[0046] Add 8g of polyacrylamide solution with a concentration of 40wt% to the obtained alumina fiber slurry, stir and disperse the slurry at a speed of 1000r / min for 5min to obtain a uniformly dispersed mixed slurry; adding a dispersant can make the alumina The fiber dispersion is more uniform, and the degree of agglomeration of alumina fibers is low at a speed of 1000r / min, and the dispersion is uniform.

[0047] The obtained mixed slurry is subjected to suction and dehydration treatment with a suction molding machine to obtain alumina fiber paper 1 with a thickness of 2±0.5mm, which is easy to control the size and facilitate subsequent processing; the suction vacuum degree is 0.08-1.0 MPa, the size of filter cloth is 380×780mm 2 ;

[0048] Graphite paper 2 is subjected to vacuum pre-oxidation treatment, wherein t...

Embodiment 2

[0053] Mix 65g of alumina fiber with 5200g of deionized water, and use a high-speed stirrer to stir and mix at 1000r / min for 5min to obtain alumina fiber slurry;

[0054] Add 10 g of a polyacrylamide solution with a concentration of 60 wt % to the obtained alumina fiber slurry, and stir and disperse the slurry at a speed of 1000 r / min for 5 minutes to obtain a uniformly dispersed mixed slurry;

[0055] Use a suction forming machine to filter and dehydrate the obtained mixed slurry to obtain alumina fiber paper with a thickness of 2±0.5mm; the vacuum degree of suction is 0.08-1.0MPa, and the size of the filter cloth is 380×780mm 2 ;

[0056] Graphite paper is subjected to vacuum pre-oxidation treatment, wherein the vacuum pre-oxidation treatment is raised to 1200 °C at a heating rate of 5 °C / min, kept for 1 hour and then cooled with the furnace;

[0057] The aluminum phosphate solution with a solid content of 40wt% is used to bond the alumina fiber paper and the graphite paper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com