Preparation method of low-density carbon fiber reinforced carbon aerogel composite material

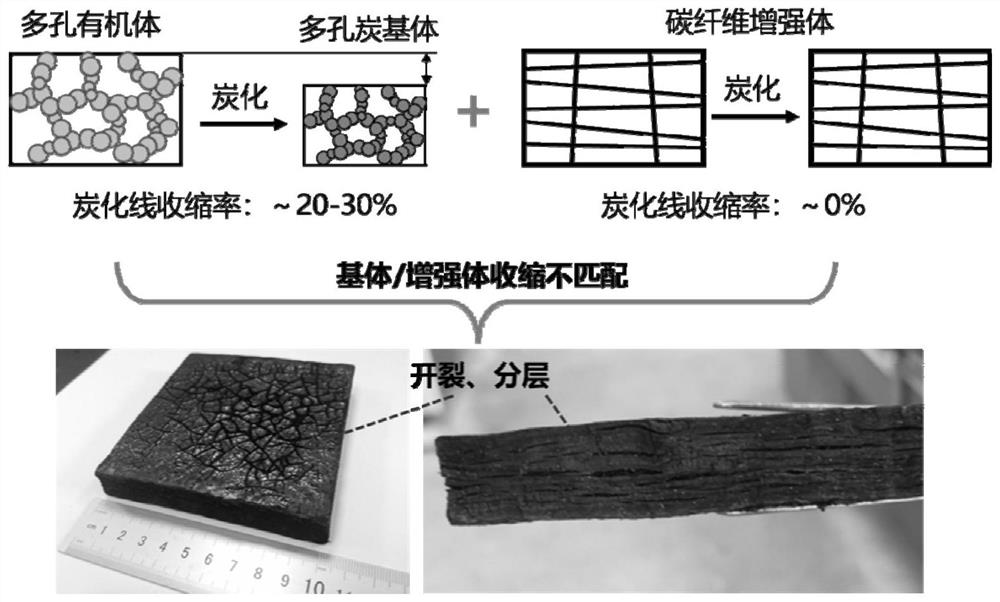

A composite material and carbon airgel technology, which is applied in the direction of airgel preparation, carbon preparation/purification, chemical instruments and methods, etc., can solve the problems of composite material delamination, cracking, poor shrinkage matching between fiber and matrix, etc. Achieve the effect of simple equipment requirements, safe and simple operation, and excellent high-temperature heat insulation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

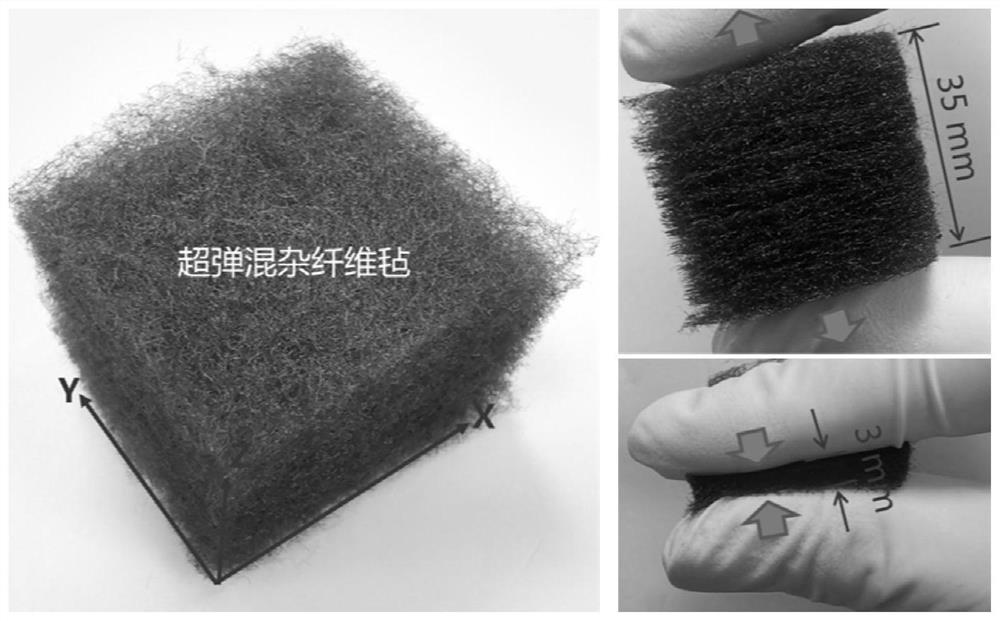

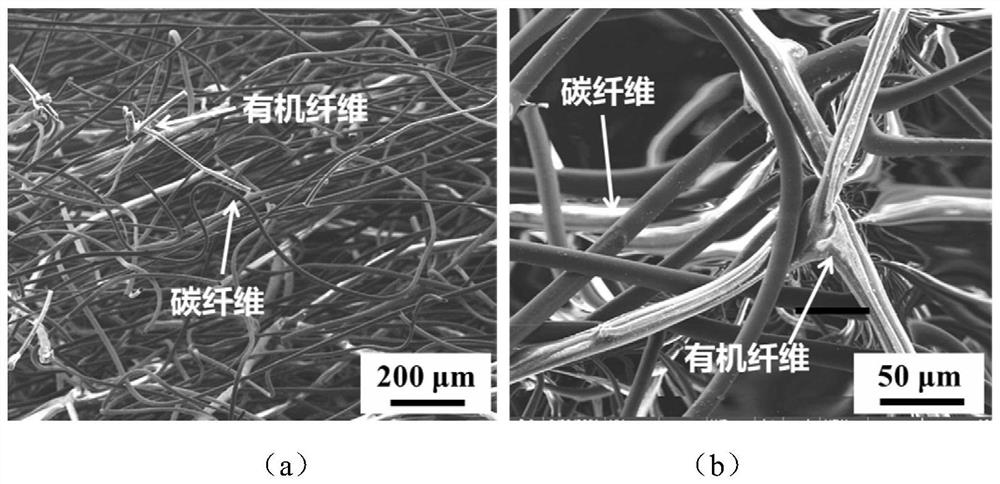

Method used

Image

Examples

Embodiment 1

[0047] Mix phenolic resin, ethylene glycol, hexamethylenetetramine, and deionized water uniformly in a mass ratio of 3:20:1:10; In the mold of the elastic hybrid fiber felt, and keep the pressure for 24h; continue to impregnate with 0.1MPa nitrogen atmosphere pressure for 6h, and then cure and keep it for 10h at the temperature of the furnace cavity at 180°C to obtain the phenolic wet gel reinforced by the hybrid fiber; Dry in a drying oven at 120°C under normal pressure for 10 hours to obtain hybrid fiber-reinforced phenolic aerogels; put the obtained super-elastic hybrid fiber-reinforced phenolic airgel into a carbonization furnace, and in an argon atmosphere at 5°C / min The rate of heating was raised to 650°C, and the carbon fiber-reinforced carbon airgel composite material was obtained after holding the temperature for 1 hour. The normal pressure drying line shrinkage of the carbon airgel composite prepared by the above process is 0.75%, and the bulk density is 0.16g / cm 3 ...

Embodiment 2

[0051] Mix phenolic resin, ethanol, benzenesulfonyl chloride, and deionized water uniformly in a mass ratio of 3:12:4:8; under an atmospheric pressure of 0.1MPa, introduce the mixed solution into a superelastic hybrid fiber mat In the mold, and the vacuum holding time is 24h; continue to impregnate with 5MPa nitrogen atmosphere pressure for 6h, and then cure and keep at 200℃ furnace temperature for 5h under 10MPa nitrogen atmosphere pressure to obtain hybrid fiber reinforced phenolic wet gel; After molding, dry in a drying oven at 100°C under normal pressure for 48 hours to obtain hybrid fiber-reinforced phenolic airgel; put the obtained super-elastic hybrid fiber-reinforced phenolic airgel into a carbonization furnace, and heat it at 6°C under an argon atmosphere. The temperature was raised to 900°C at a rate of 1 / min, and the carbon fiber-reinforced carbon airgel composite was obtained after holding for 2 hours. The atmospheric pressure drying line shrinkage rate of the carb...

Embodiment 3

[0054] Mix phenolic resin, isopropanol, p-toluenesulfonic acid, and deionized water uniformly in a mass ratio of 3:10:1:4; In the mold of the fiber felt, the vacuum holding time is 36h; the impregnation is continued at 4MPa nitrogen atmosphere pressure for 8h, and then cured at 6MPa nitrogen atmosphere pressure and 200°C oven temperature for 6h to obtain hybrid fiber reinforced phenolic wet gel; After demoulding, dry in a drying oven at 90°C under normal pressure for 48 hours to obtain a hybrid fiber-reinforced phenolic airgel; put the obtained super-elastic hybrid fiber-reinforced phenolic airgel into a carbonization furnace, and heat it at 6°C under an argon atmosphere. The temperature was raised to 900°C at a rate of 1 / min, and the carbon fiber-reinforced carbon airgel composite was obtained after holding for 2 hours. The atmospheric pressure drying line shrinkage rate of the carbon airgel composite material prepared by the above process is 1.39%, and the bulk density is 0....

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bulk density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com