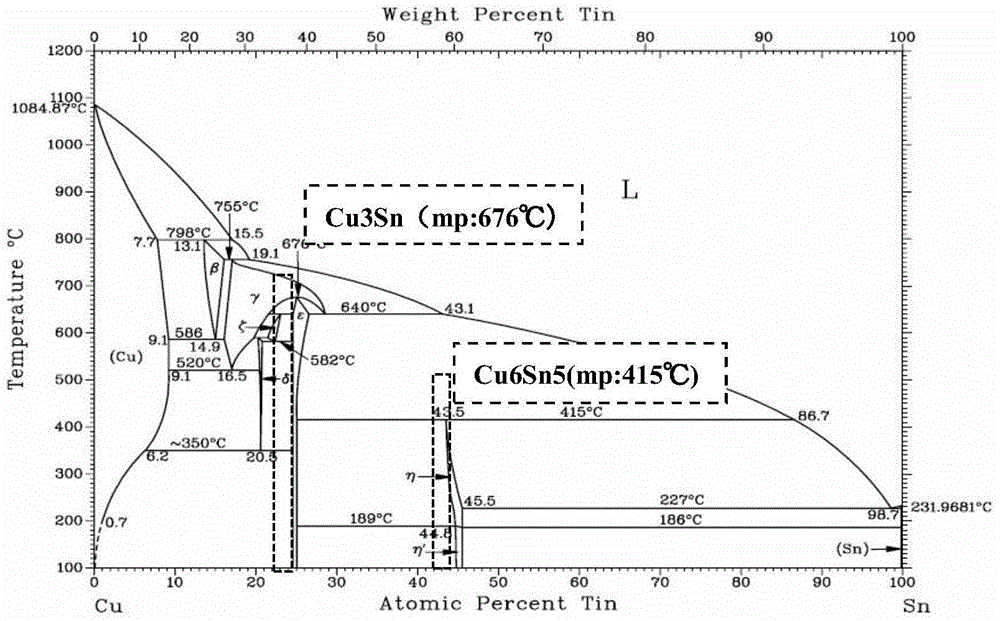

Sn-Cu high-temperature lead-free soldering paste, preparation method thereof and application method thereof

A lead-free solder paste, sn-cu technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problem of not being able to provide such products, and achieve the effects of improved mechanical properties, low cost, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

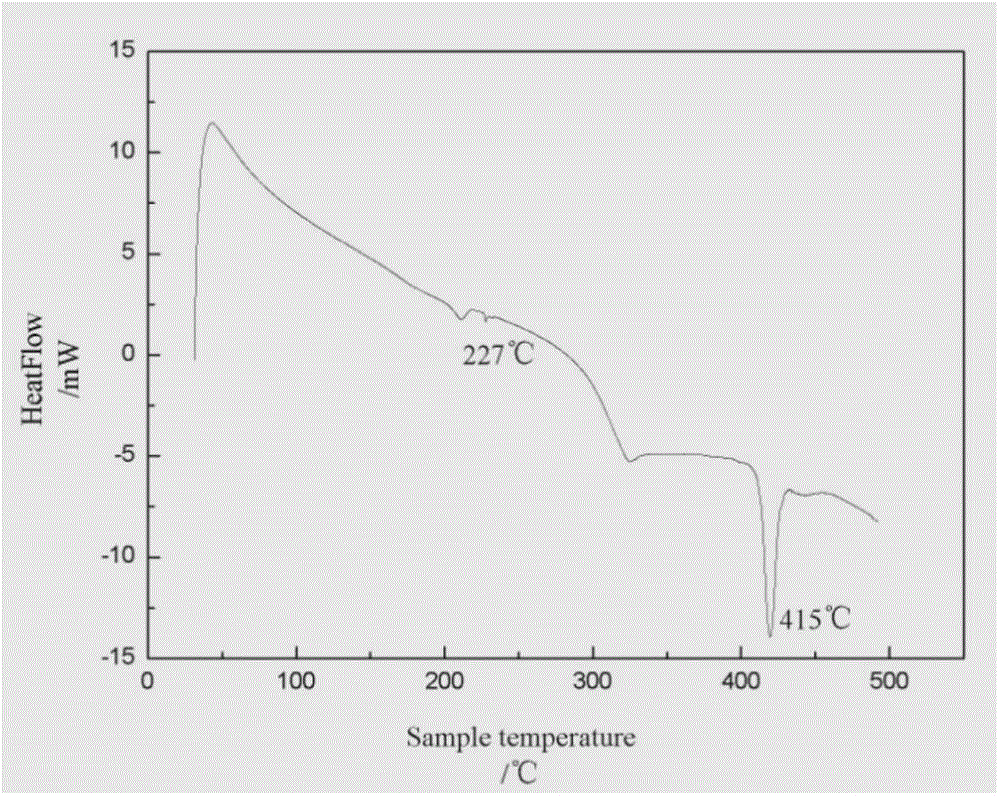

Method used

Image

Examples

Embodiment 1

[0035] Spherical or nearly spherical copper powder with a particle size of 0.1 μm and tin powder with a particle size of 1 μm were added with rosin-type flux with a viscosity of 1 Pa·s, and mechanically mixed for 15 minutes at a speed of 1000 rpm by a high-speed mixer to obtain the obtained Solder paste is required; the mass percentage of each component of the solder paste is copper: tin: disproportionated rosin flux 40%: 40%: 20%.

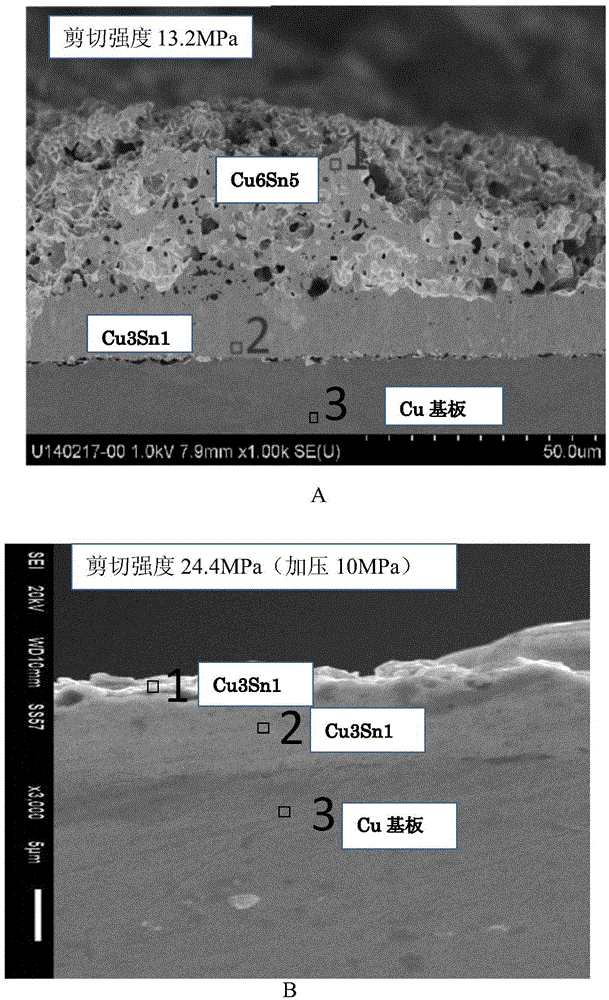

[0036] Take 2 groups of copper sheet weldments, and apply the solder paste prepared above evenly on these 2 groups of copper sheet weldments; Group A heat treatment at 250-300 ° C for 2 hours in an argon atmosphere, and cool with the furnace; Group B in argon atmosphere Heat treatment at 250-300°C for 2 hours in the atmosphere, and at the same time, use a hot press to apply a pressure of 5 MPa to the weldment to the area where the solder paste is applied, and cool with the furnace;

[0037]Take out the weldment, and test the shear strength of the ...

Embodiment 2

[0039] Spherical or nearly spherical copper powder with a particle size of 1 μm and tin powder with a particle size of 5 μm were added with rosin-type flux with a viscosity of 8 Pa s, and mechanically mixed for 10 minutes at a speed of 1800 rpm by a high-speed mixer to obtain the obtained Solder paste is required; the mass percentage of each component of the solder paste is, copper: tin: disproportionated rosin flux is 20%: 60%: 20%.

[0040] Take 2 groups of copper sheet weldments, and apply the solder paste prepared above evenly on the 2 groups of copper sheet weldments; group A is heat treated at 250-300°C in a nitrogen atmosphere for 1 hour; group B is heat-treated at 250-300°C in a nitrogen atmosphere 1h, at the same time, use a hot press to apply a pressure of 6MPa to the weldment to the area where the solder paste is applied;

[0041] Take out the weldment, and test the shear strength of the weld of the welded sample at 350°C with a universal mechanical testing machine ...

Embodiment 3

[0043] Spherical or nearly spherical copper powder with a particle size of 0.2 μm and tin powder with a particle size of 2 μm were added with rosin-type flux with a viscosity of 3 Pa s, and mechanically mixed for 12 minutes at a speed of 1500 rpm by a high-speed mixer to obtain the obtained Solder paste is required; the mass percentage of each component of the solder paste is, copper: tin: natural rosin flux is 35%: 50%: 15%.

[0044] Take 2 groups of copper sheet weldments, and apply the solder paste prepared above evenly on the 2 groups of copper sheet weldments; group A heat treatment at 250-300 °C for 6 hours in an argon atmosphere; group B in an argon atmosphere at 250-300 ℃ heat treatment for 6 hours, and at the same time, use a hot press to apply a pressure of 7 MPa to the weldment to the area where the solder paste is applied;

[0045] Take out the weldment and test the shear strength of the weld of the welded sample at 350°C with a universal mechanical testing machine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com