Surface protection film and propylene copolymer composition for surface protection film

A surface protection film, propylene copolymer technology, used in film/sheet adhesives, synthetic resin layered products, layered products, etc. problems such as low force, and achieve the effect of sufficient transparency, excellent anti-blocking, and excellent pull-out

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0084] In the preparation of the solid catalyst component (A1), any electron donating compound (c) can be used as needed. These electron donating compounds (c) are usually organic compounds containing oxygen, nitrogen, phosphorus or sulfur, for example, amines, amides, ketones, nitriles, phosphines, esters, ethers, and thioethers can be cited , Alcohols, thioesters, acid anhydrides, acid halides, aldehydes, organic acids, organic silicon compounds with Si-OC bonds.

[0085] Specifically, for example, aromatic phthalate diesters such as diethyl phthalate, dibutyl phthalate, diisobutyl phthalate, and dihexyl phthalate can be preferably exemplified , Dimethyldimethoxysilane, diethyldiethoxysilane, diphenyldimethoxysilane, cyclohexylmethyldimethoxysilane, di-tert-butyldimethoxysilane, diiso Organosilicon compounds such as butyldimethoxysilane, diisopropyldimethoxysilane, dicyclohexyldimethoxysilane, and dicyclopentyldimethoxysilane.

[0086] As a preparation method of the solid catal...

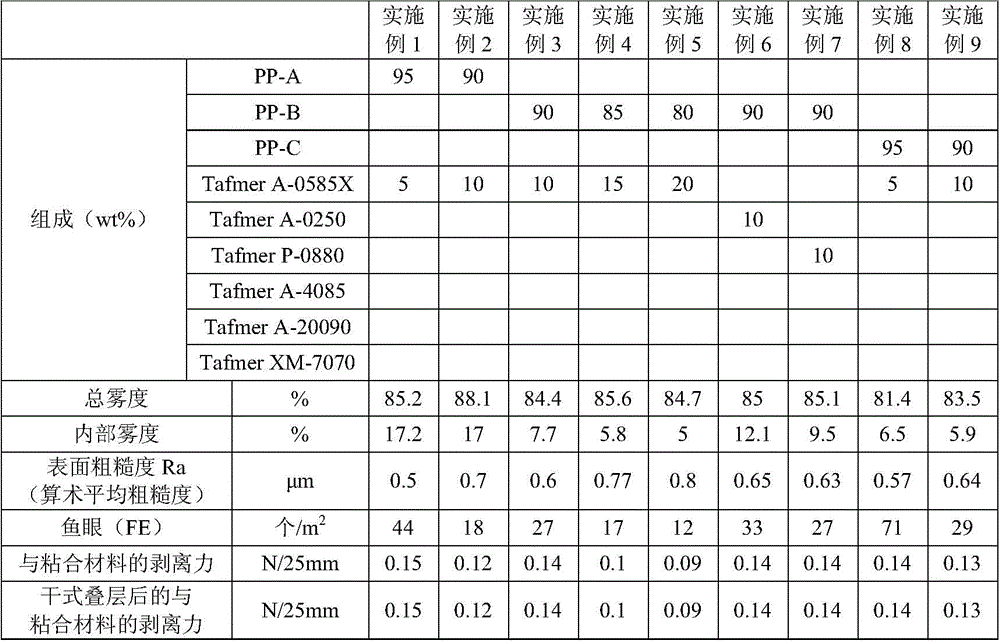

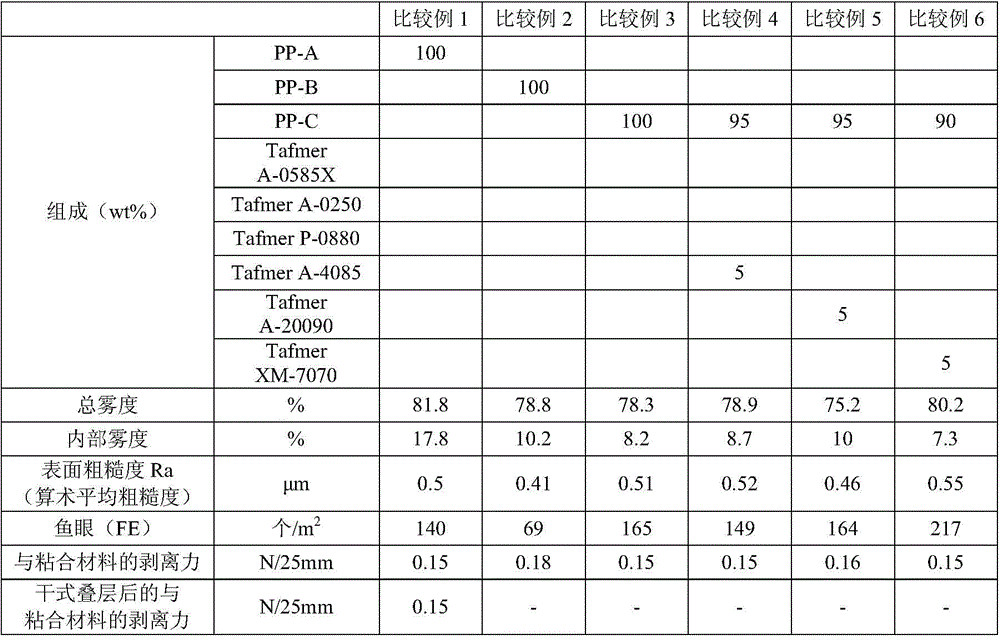

Embodiment

[0166] Hereinafter, the present invention will be described more specifically based on examples, but the present invention is not limited by these examples.

[0167] The measuring methods of physical properties in the examples and comparative examples are as follows.

[0168] (1) MFR (melt flow rate)

[0169] MFR is measured in accordance with ASTM D1238 (230°C or 190°C, load 2.16 kg).

[0170] (2) Room temperature n-decane soluble part (D sol )

[0171] 200 ml of n-decane was added to 5 g of a sample of the final product (that is, the propylene-based random block polymer of the present invention), and the mixture was heated at 145°C for 30 minutes to dissolve. It takes about 3 hours to cool down to 20°C and let stand for 30 minutes. After that, the precipitate (hereinafter referred to as the n-decane insoluble part: D insol ). The filtrate was added to approximately 3 times the amount of acetone, and the components dissolved in n-decane were separated out (precipitate (A)). The pr...

manufacture example 1

[0192] [Production Example 1] (Production of propylene-ethylene block copolymer)

[0193] (1) Preparation of magnesium compounds

[0194] The reaction tank with a stirrer (inner volume of 500 liters) is fully replaced with nitrogen, 97.2 kg of ethanol, 640 g of iodine and 6.4 kg of magnesium metal are added, and the reaction is carried out under reflux conditions while stirring until there is no more hydrogen in the system, and a solid is obtained. Shape reaction product. The reaction liquid containing the solid reaction product is dried under reduced pressure to obtain the target magnesium compound (support for the solid catalyst).

[0195] (2) Preparation of solid catalyst components

[0196] Into a reaction tank with a stirrer (inner volume 500 liters) fully replaced with nitrogen, 30 kg of the above-mentioned magnesium compound (not crushed), 95 liters of purified heptane (n-heptane), 4.4 liters of silicon tetrachloride and o-benzene were added 6.0 liters of di-n-butyl dicarboxy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com