Polyethylene-based resin composition, polyethylene-based film

A technology of polyethylene-based resin and composition, applied in the field of polyethylene-based resin composition, can solve problems such as inability to show, and achieve the effects of full transparency and strong wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

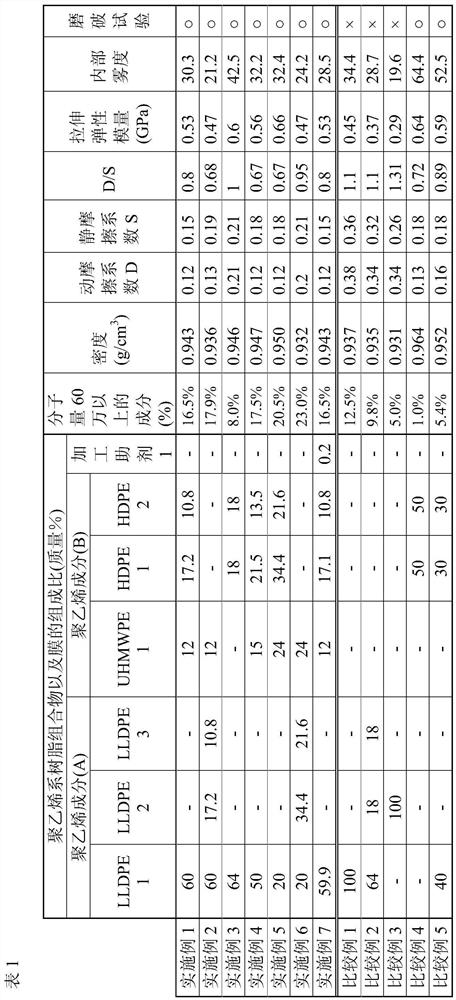

Examples

Embodiment 1

[0180] After mixing 55.5 mass % of UHMWPE1 and 44.5 mass % of HDPE1, it melt-kneaded using the Toshiba Machine Co., Ltd. TEM-18ss twin-screw extruder (L / D=50). Adjust the feeder to knead in such a way that the temperature = 215° C., the screw speed = 200 rpm, and the discharge rate is about 1 to 2 kg / Hr to obtain a high-concentration dilution of the polyethylene-based resin composition.

[0181] After mixing 66.7% by mass of the high-concentration dilution of the polyethylene-based resin composition obtained above with 33.3% by mass of HDPE2, it was charged into the above-mentioned twin-screw extruder and subjected to the second melt-kneading. The feeder was adjusted so that the temperature = 210° C., the screw speed = 200 rpm, and the discharge rate was 1 to 2 kg / Hr, and kneaded to obtain pellets of the first intermediate of the polyethylene-based resin composition.

[0182] After mixing 81.1 mass % of the 1st intermediate body of the polyethylene-type resin composition obtai...

Embodiment 2

[0188] After mixing 55.5% by mass of UHMWPE1 and 44.5% by mass of LLDPE2, it was melt-kneaded using a TEM-18ss twin-screw extruder (L / D=50) manufactured by Toshiba Machine Co., Ltd. Adjust the feeder to knead in such a way that the temperature = 215° C., the screw speed = 200 rpm, and the discharge rate is about 1 to 2 kg / Hr to obtain a high-concentration dilution of the polyethylene-based resin composition.

[0189] After mixing 66.7% by mass of the high-concentration dilution of the polyethylene-based resin composition obtained above with 33.3% by mass of LLDPE3, it was charged into the above-mentioned twin-screw extruder, and subjected to the second melt-kneading. The feeder was adjusted so that the temperature = 210° C., the screw speed = 200 rpm, and the discharge rate was 1 to 2 kg / Hr, and kneaded to obtain the first intermediate of the polyethylene-based resin composition.

[0190] After mixing 81.1 mass % of the 1st intermediate body of the polyethylene-type resin comp...

Embodiment 3

[0195] After mixing 50% by mass of HDPE1 and 50% by mass of HDPE2, it was melt-kneaded using a Toshiba Machine Co., Ltd. TEM-18ss twin-screw extruder (L / D=50). The feeder was adjusted so that the temperature = 205° C., the screw speed = 200 rpm, and the discharge rate was about 3 to 5 kg / Hr, and kneaded to obtain a polyethylene-based resin composition intermediate.

[0196] After mixing 36% by mass of the polyethylene-based resin composition intermediate obtained above and 64% by mass of LLDPE1, it was charged into the above-mentioned twin-screw extruder, and subjected to the second melt-kneading. The feeder was adjusted so that the temperature = 210°C, the screw speed = 200 rpm, and the discharge rate was about 3 to 5 kg / Hr, and kneaded to obtain pellets of the polyethylene-based resin composition.

[0197] The pellets were supplied to the extruder of a single-layer inflation molding machine, and the molten resin extruded from a die at 200°C at 2.5Kg / Hr was subjected to infla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| haze | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com