Perspective eraser and preparation method thereof

An eraser and paraffin technology, applied in the eraser field, can solve the problems of poor word erasing performance, low transparency, easy to break, etc., and achieve the effect of excellent word erasing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A see-through eraser and its preparation method. The see-through eraser is prepared from the following components according to the following proportions by weight: 45-55 parts of polyvinyl chloride paste resin; 45-60 parts of plasticizer; paraffin wax 0.1-0.5 parts; sodium cocoyl isethionate 0.1-0.5 parts; organic tin stabilizer 0.1-0.5 parts; epoxy soybean oil 1-8 parts; calcium carbonate 0-0.5 parts, phthalocyanine blue 0.0001-0.0005 share.

[0022] The preparation method comprises the following steps:

[0023] (1) Slurry preparation: Turn on the stirring, add all the raw materials into the homogenization equipment according to the proportion, turn on the vacuum device, and vacuumize while stirring to defoam. When there are almost no fine particles in the slurry, stop stirring;

[0024] (2) Filtration of slurry: filter the slurry through a filter screen, and continue to place the obtained slurry in a homogenizer to vacuumize and defoam;

[0025] (3) Mold grouting: ...

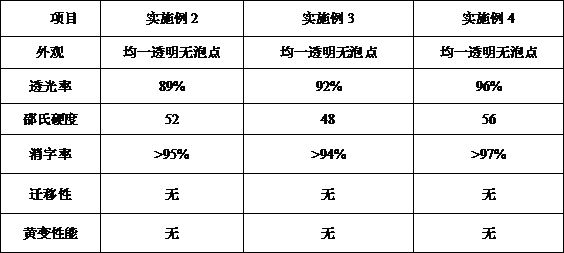

Embodiment 2

[0034] A see-through eraser and a preparation method thereof. The see-through eraser is prepared from the following components according to the following proportions by weight: 45 parts of polyvinyl chloride paste resin; 48 parts of plasticizer; 0.5 part of paraffin; 0.25 parts of sodium oleyl isethionate; 0.25 parts of organic tin stabilizer; 5.5 parts of epoxy soybean oil; 0.5 parts of calcium carbonate, 0.0001 parts of phthalocyanine blue.

[0035] The preparation method comprises the following steps:

[0036] (1) Slurry preparation: Turn on the stirring, add all the raw materials into the homogenization equipment according to the proportion, turn on the vacuum device, and vacuumize while stirring to defoam. When there are almost no fine particles in the slurry, stop stirring;

[0037] (2) Filtration of slurry: filter the slurry through a filter screen, and continue to place the obtained slurry in a homogenizer to vacuumize and defoam;

[0038] (3) Mold grouting: Open the...

Embodiment 3

[0045] A see-through eraser and a preparation method thereof. The see-through eraser is prepared from the following components according to the following proportions by weight: 48 parts of polyvinyl chloride paste resin; 45 parts of plasticizer; 0.5 part of paraffin; 0.25 parts of sodium oleyl isethionate; 0.25 parts of organic tin stabilizer; 5.5 parts of epoxy soybean oil; 0.5 parts of calcium carbonate, 0.0003 parts of phthalocyanine blue.

[0046] The preparation method comprises the following steps:

[0047] (1) Slurry preparation: Turn on the stirring, add all the raw materials into the homogenization equipment according to the proportion, turn on the vacuum device, and vacuumize while stirring to defoam. When there are almost no fine particles in the slurry, stop stirring;

[0048] (2) Filtration of slurry: filter the slurry through a filter screen, and continue to place the obtained slurry in a homogenizer to vacuumize and defoam;

[0049] (3) Mold grouting: Open the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com