Core/shell structure fiber film-based gel polymer electrolyte and preparation method thereof

A gel polymer and shell structure technology, applied in the direction of conjugated synthetic polymer artificial filaments, circuits, electrical components, etc., can solve problems such as hindering commercial applications, loss of electrochemical properties, and decline in mechanical properties, and achieve stability The effect of electrochemical window, good charge and discharge performance, strong adsorption and retention ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

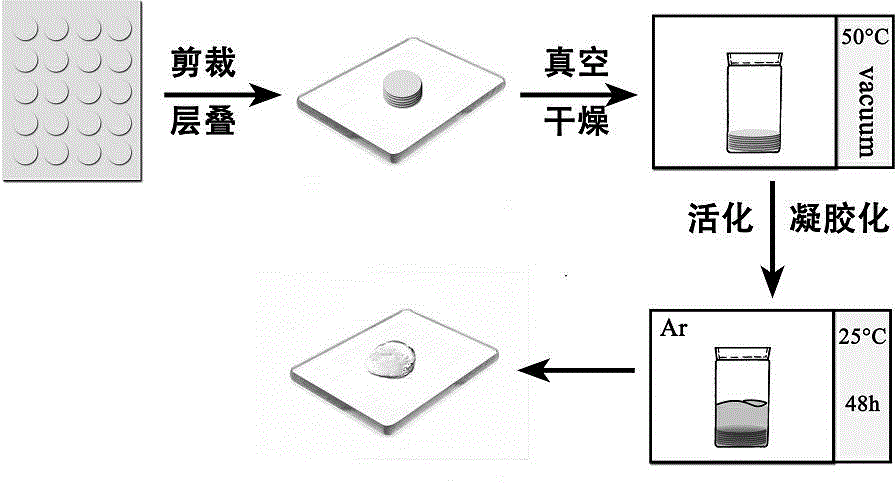

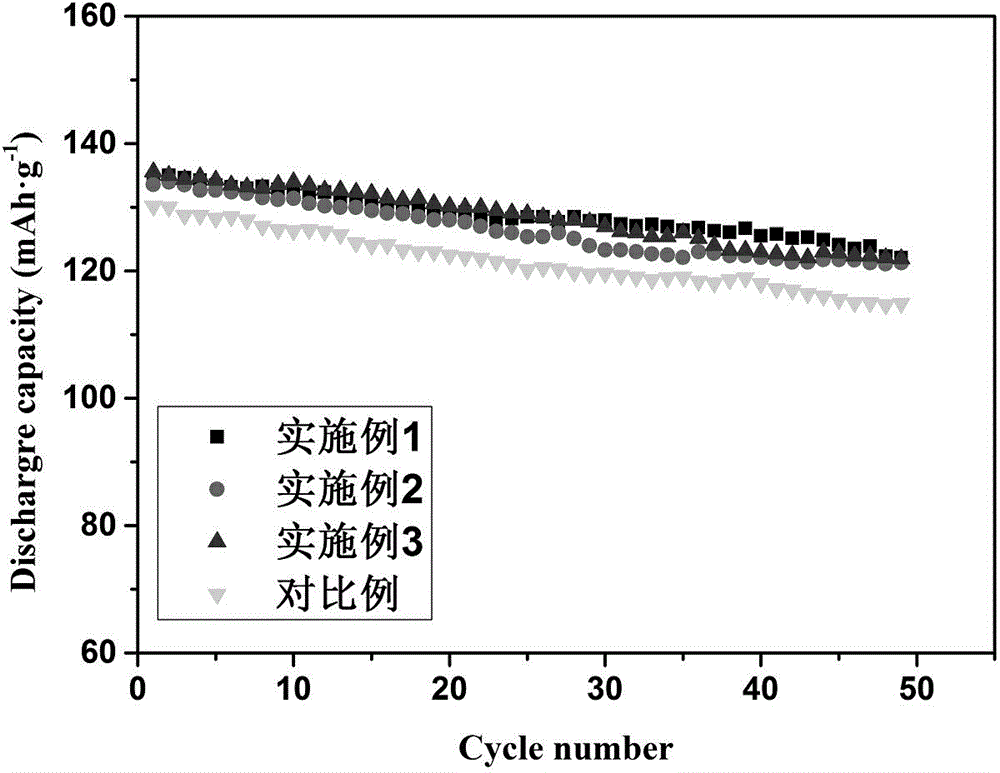

Embodiment 1

[0022] Component 1 is polyacrylonitrile with a molecular weight of 10 5 g / mol (Mw), the manufacturer is UK Courtaulds Co. Component 2 is polymethyl methacrylate with a molecular weight of 1.0~1.3×10 5 g / mol (Mw), the manufacturer is Aldrich Chemical Co. Component 3 is 1mol / L LiPF 6 / DEC-EC (molar ratio is 1:1) electrolyte, the manufacturer is Beijing Chemical Plant. The solvent used for the core layer and the shell layer spinning solution is N,N-dimethylformamide, wherein the concentration of the core layer spinning solution is 14wt%, and the concentration of the shell layer spinning solution is 20wt%. During the coaxial electrospinning process The flow rate ratio of the core spinning liquid to the shell spinning liquid is 0.5. The polymer fiber membrane obtained by electrospinning was dried in a vacuum oven at 50 °C for 8 h to remove residual moisture and solvent. Then it was cut into discs with a diameter of 22 mm, laminated and compacted, with a total weight of 78 mg,...

Embodiment 2

[0025] Component 1 is polyvinylidene fluoride, molecular weight 5.3×10 5 g / mol (Mw), the manufacturer is Aldrich Chemical Co. Component 2 is polyethylene oxide with a molecular weight of 10 5 g / mol (Mw), the manufacturer is Shanghai Liansheng Chemical Company. Component 3 is 1mol / L LIPF6 / DMC-EC (molar ratio 1:1) electrolyte. The solvent used for the core layer and the shell layer spinning solution is N,N-dimethylformamide, wherein the concentration of the core layer spinning solution is 10wt%, and the concentration of the shell layer spinning solution is 16wt%. During the coaxial electrospinning process The flow rate ratio of the core spinning liquid to the shell spinning liquid is 0.7. The polymer fiber membrane obtained by electrospinning was dried in a vacuum oven at 50 °C for 8 h to remove residual moisture and solvent. Then it was cut into discs with a diameter of 24 mm, laminated and compacted, with a total weight of 85 mg, and vacuum-dried at 60° C. for 20 h to ob...

Embodiment 3

[0028] Component 1 is polyacrylonitrile with a molecular weight of 10 5 g / mol (Mw), the manufacturer is UK Courtaulds Co. Component 2 is polyethylene oxide with a molecular weight of 10 5 g / mol (Mw), the manufacturer is Shanghai Liansheng Chemical Company. Component 3 is 1mol / L LIPF6 / DEC-EC (molar ratio 1:1) electrolyte. The solvent used for the core layer and the shell layer spinning solution is N,N-dimethylformamide, wherein the concentration of the core layer spinning solution is 12wt%, and the concentration of the shell layer spinning solution is 18wt%. During the coaxial electrospinning process The flow rate ratio of the core spinning liquid to the shell spinning liquid is 0.8. The polymer fiber membrane obtained by electrospinning was dried in a vacuum oven at 50 °C for 8 h to remove residual moisture and solvent. Then it was cut into discs with a diameter of 20 mm, laminated and compacted, with a total weight of 70 mg, and vacuum-dried at 60° C. for 20 h to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com