Underfill adhesive, as well as preparation method and application thereof

An underfill and epoxy resin technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of the decline of adhesive performance, affecting the storage period, and adding a large amount of reactive diluents, etc. The effect of reducing viscosity, excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

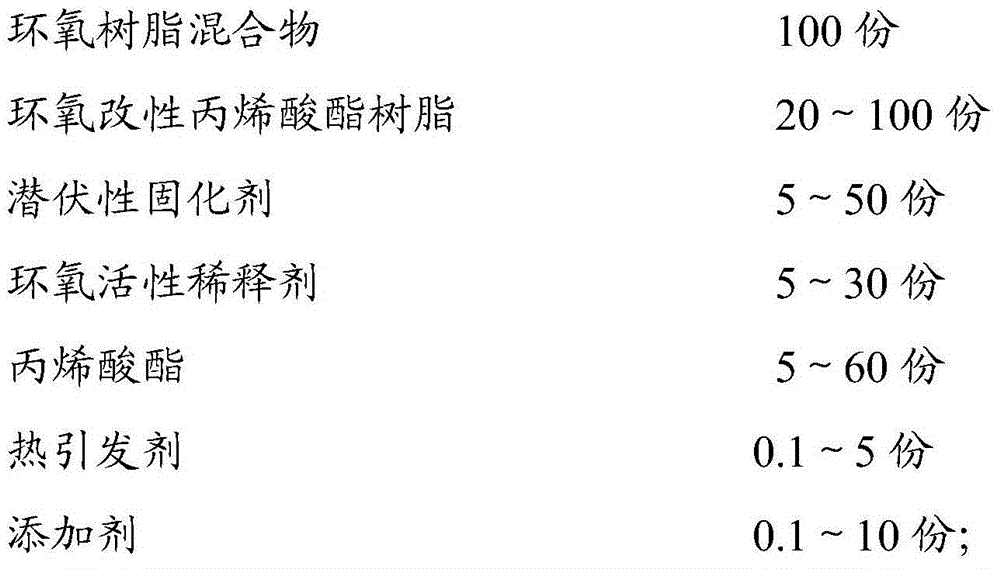

Method used

Image

Examples

Embodiment 1

[0028] The preparation of embodiment 1:

[0029] Add DER332 into the stirring tank first, heat to 80 degrees, and stir until the epoxy resin is completely free of crystals and forms a uniform liquid. Cool to room temperature, add EBECRYL 3701, glycidyl methacrylate, glycidyl o-cresyl ether, SR506, carbon black, and stir for 120 minutes; add Fujicure 1090, and stir for 30 minutes. Use a three-roller to grind to a fineness of less than 5um. Add tert-butyl peroxide-2-ethylhexanoate into the planetary mixer, while vacuuming, keep the vacuum at -0.1MPa, and mix for 45 minutes.

Embodiment 2

[0030] The preparation of embodiment 2:

[0031] Add EPILCON 830LVP, EP-4100HF, PB3600 to the stirred tank and heat to 90 degrees, stir until the epoxy resin is completely free of crystals and forms a uniform liquid. Cool to room temperature, add CYLOMERM100, glycidyl methacrylate, SR506, R833, carbon black, and stir for 90 minutes; add HX-3721, and stir for 30 minutes. Use a three-roller to grind to a fineness of less than 5um. Add tert-butyl peroxide-2-ethylhexanoate into the planetary mixer, and at the same time vacuumize, keep the vacuum at -0.1MPa, and mix for 30 minutes.

Embodiment 3

[0032] The preparation of embodiment 3:

[0033] Add EPILCON 830LVP, EP-4100HF, PB3600 into the stirred tank first, heat to 70 degrees, and stir until the epoxy resin is completely free of crystals and forms a uniform liquid. Cool to room temperature, add EBECRYL3701, glycidyl methacrylate, CN981, SR506, carbon black, and stir for 60 minutes; add PN40, HX3721, and stir for 45 minutes. Use a three-roller to grind to a fineness of less than 5um. Add tert-butyl peroxide-2-ethylhexanoate, ester azobisisobutyronitrile into the planetary mixer, and vacuumize at the same time, keep the vacuum at -0.1MPa, and mix for 45 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com