Catalyst feeding device for polymerization process of ultra-high molecular weight polyethylene and application

An ultra-high molecular weight, polymerization process technology, applied in the field of catalyst feeding devices, can solve problems such as blockage of catalyst feeding pipelines, and achieve the effects of reducing agglomeration, reducing the proportion of large particles, and increasing bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Catalyst feed unit for UHMWPE polymerization process:

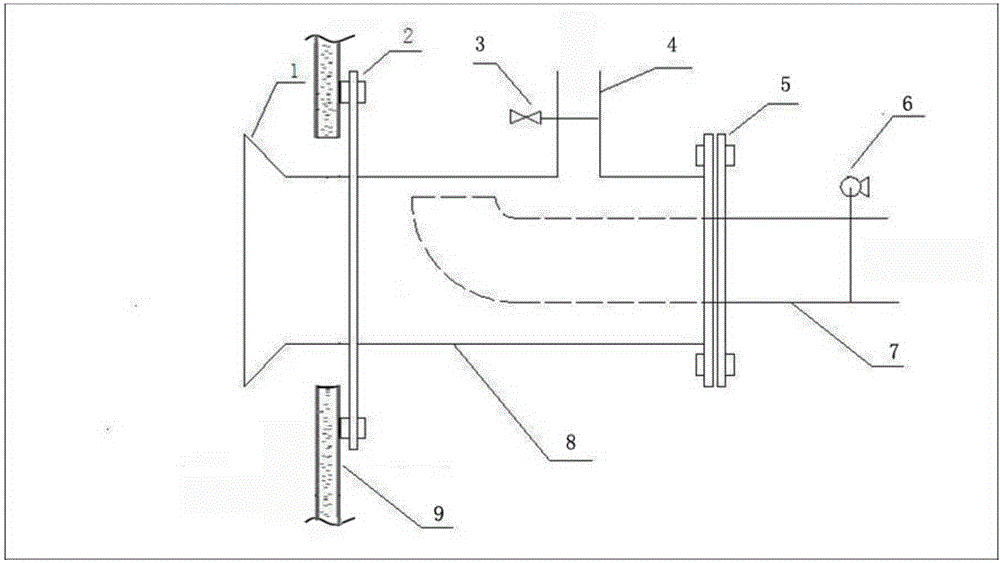

[0047] Such as figure 1 Shown, comprise catalyst feeding pipe 7, metering pump 6 is arranged on catalyst feeding pipe 7, catalyst premixing pipe 8 is arranged on catalyst feeding pipe 7 outer axis, catalyst feeding pipe 7 and catalyst premixing pipe 8 pass through the first method The flange 5 is connected, the catalyst premixing pipe 8 is provided with a solvent feed pipe 4, the solvent feed pipe 4 is provided with an electromagnetic flow regulating valve 3, and the catalyst premixing pipe 8 is connected to the polymerization kettle 9 through the second flange 2. The catalyst feeding device can be connected to the side wall of the polymerization kettle 9 . The end of the catalyst feeding pipe 7 near the end of the polymerization kettle 9 is a 90-degree elbow. The ends are 90 degree elbows. The gap between the port of the 90-degree elbow and the inner wall of the catalyst premixing pipe 8 is 4 cm. The port wher...

Embodiment 2

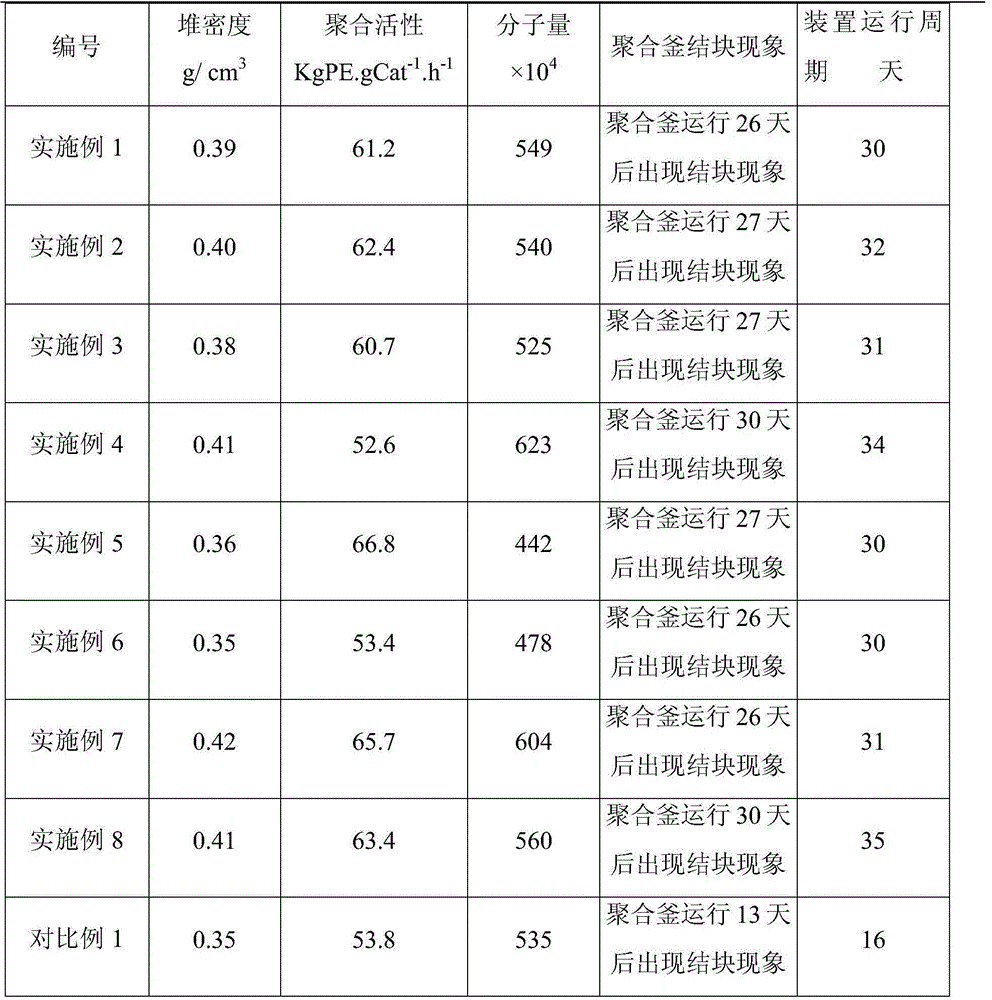

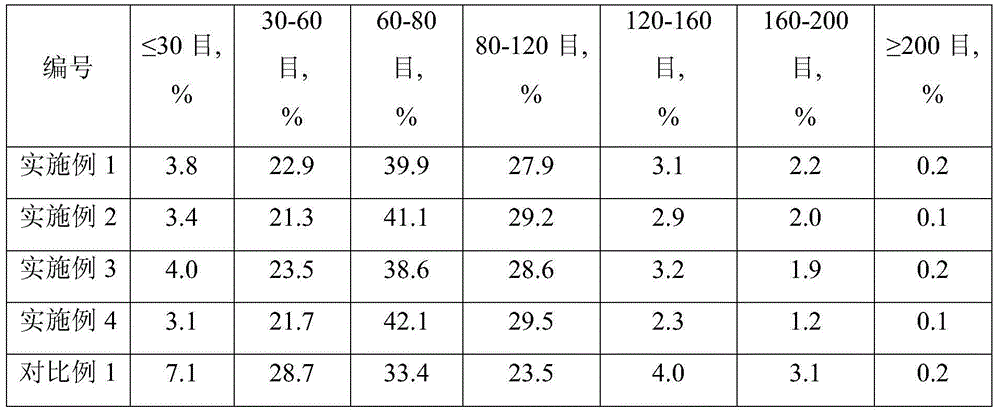

[0055] The ultra-high molecular weight polyethylene resin was prepared using the same device and method as in Example 1, but the solvent flow rate of the outer pipe of the catalyst feed pipe was set at 25 L / min. The polymerization performance and resin performance are shown in Table 1 and Table 2.

Embodiment 3

[0057] The ultra-high molecular weight polyethylene resin was prepared with the same device and method as in Example 1, but the flow rate of the catalyst slurry in the catalyst feed pipe was set at 0.5 L / min. The polymerization performance and resin performance are shown in Table 1 and Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com