A kind of oil sludge demulsifier and oil sludge advanced treatment process

A demulsifier and oil sludge technology, which is applied in sludge treatment, water/sludge/sewage treatment, dewatering/drying/concentrated sludge treatment, etc. problem, to achieve good demulsification performance, good demulsification effect, and easy industrial application.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

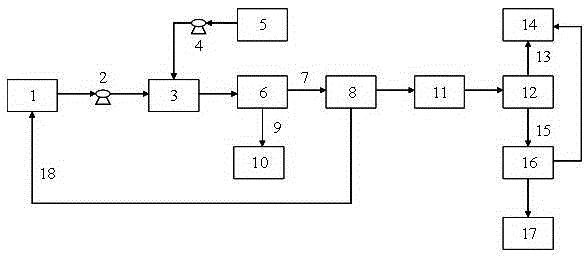

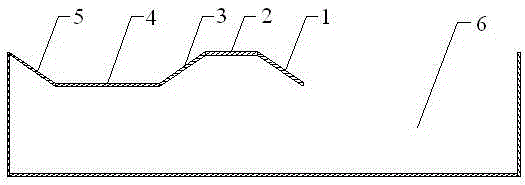

Method used

Image

Examples

Embodiment 1

[0034] Polyglyceryl fatty acid ester (R=C 17 ), 15 parts of polyoxyethylene oleate (n=4), 1 part of sodium citrate, and 76 parts of water were uniformly mixed in a reaction kettle at a temperature of 55°C for 45 minutes to obtain a sludge demulsifier.

Embodiment 2

[0036] Polyglyceryl fatty acid ester (R=C 16 ), 12 parts of polyoxyethylene oleate (n=3), 1 part of sodium citrate, and 79 parts of water were uniformly mixed in a reaction kettle at a temperature of 50°C for 50 minutes to obtain a sludge demulsifier.

Embodiment 3

[0038] Polyglyceryl fatty acid ester (R=C 17 ), 6 parts of polyoxyethylene oleate (n=3), 1 part of sodium citrate, and 68 parts of water were uniformly mixed in a reaction kettle at a temperature of 55°C for 50 minutes to obtain a sludge demulsifier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com