A kind of solid polymer electrolyte porous membrane membrane liquid and membrane-making method thereof

A solid polymer and electrolyte technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, circuits, etc., can solve the problems of electrolyte absorption rate and poor mechanical properties, and achieve simple operation, high feasibility, and low equipment requirements. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

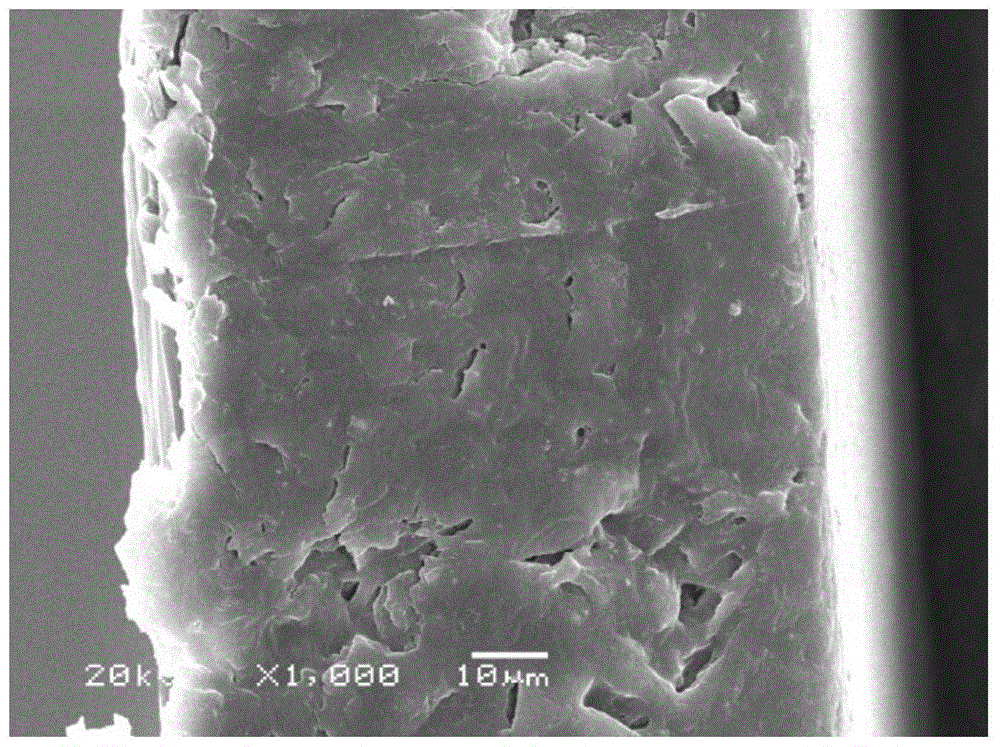

[0052] 0.4g polymethyl methacrylate (M w =550,000), 0.1g polyethylene oxide (M w =300,000), 0.025 g of lithium perchlorate were stirred and dissolved in 10 ml of N-methylpyrrolidone solvent, the boiling point of the solvent was 203° C., the stirring temperature was 40° C., and the time was 12 hours. Use 1ml injection to weigh 0.150g phytic acid solution (the mass ratio of phytic acid to water in the phytic acid solution is 1:1) and inject it into the above mixed solution, continue to stir for 1 hour, then ultrasonicate at 40°C for 30 minutes, and then let stand 5 minutes to obtain a homogeneous mixed solution.

[0053] Use a 10ml syringe to take 8ml of the film-forming solution and cast it into a petri dish (75mm in diameter), and quickly place it in a 90°C, -0.08MPa vacuum oven and cover it with white paper with small holes to dry for 24 hours. Turn off the heating in the vacuum drying oven, let it cool to room temperature, open the drying oven and wipe off the liquid in th...

Embodiment 2

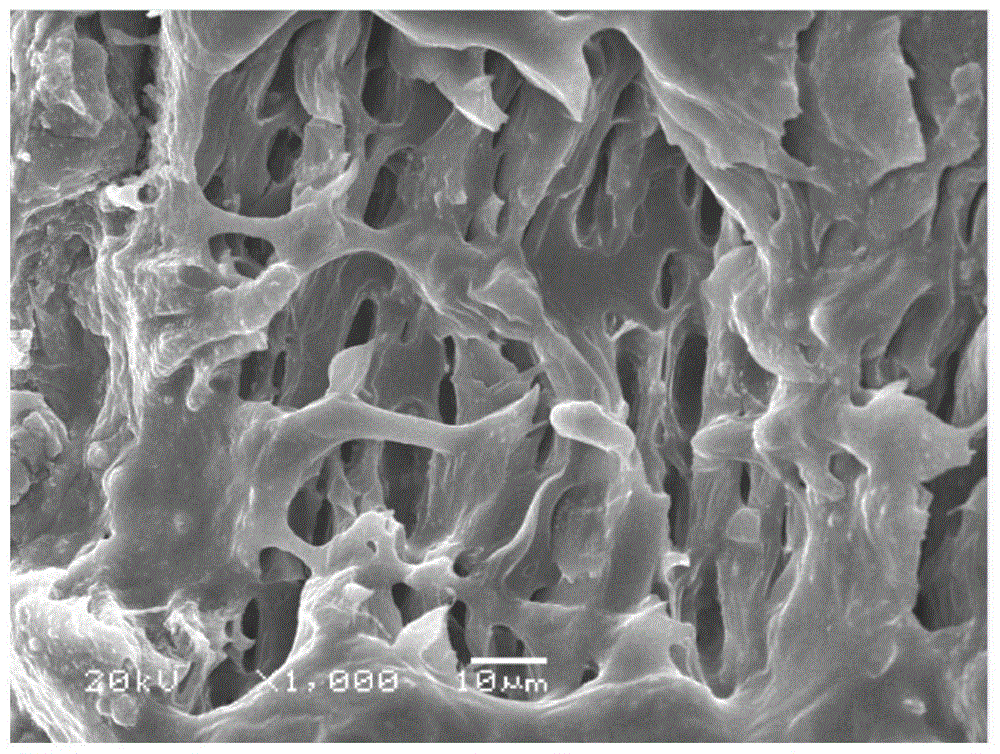

[0057] 0.4g polymethyl methacrylate (M w =550,000), 0.1g polyethylene oxide (M w =300,000), 0.025 g of lithium perchlorate were stirred and dissolved in 10 ml of N-methylpyrrolidone solvent, the boiling point of the solvent was 203° C., the stirring temperature was 40° C., and the time was 12 hours. Use 1ml injection to inject 0.25g phytic acid solution (the mass ratio of phytic acid to water in the phytic acid solution is 1:1) into the above mixed solution, continue to stir for 1 hour, then ultrasonicate at 40°C for 30 minutes, and then let it stand for 5 minutes. Minutes to obtain a homogeneous mixed solution.

[0058] Use a 10ml syringe to take 8ml of the film-forming solution and cast it into a petri dish (75mm in diameter), and quickly place it in a 90°C, -0.08MPa vacuum oven and cover it with white paper with small holes to dry for 24 hours. Turn off the heating in the vacuum drying oven, let it cool to room temperature, open the drying oven, wipe off the liquid in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com