Hollow porous micron-scale silicon sphere, silicon-based negative electrode material and preparation method of lithium ion battery

A silicon-based negative electrode material, lithium-ion battery technology, applied in the manufacture of electrolyte batteries, battery electrodes, secondary batteries, etc., can solve problems such as the inability to fundamentally suppress the volume effect, the pulverization and shedding of electrode electroactive materials, and volume expansion. , to solve the problem of cyclic charge and discharge life, eliminate pulverization and shedding, and inhibit volume expansion and contraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

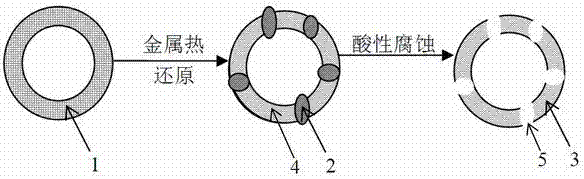

[0029] First of all, the present invention provides a method for preparing hollow porous micron-sized silicon spheres. The method includes two major steps of metallothermic reduction and pickling to remove oxides. The specific steps are as follows:

[0030] Step 1, metallothermic reduction of hollow glass microspheres. Mix active metal powder and hollow glass microspheres 1 evenly according to a certain ratio, then transfer to a crucible, heat up to the thermal reduction reaction temperature under argon protection or vacuum conditions, keep warm for a certain period of time, and cool naturally to obtain active metal oxides / silicon / silicon dioxide composite, i.e. as attached figure 1 As shown in , hollow silicon spheres 4 embedded by metal oxide 2 are obtained. In the above-mentioned heat-reduced hollow glass microspheres, the particle size of the hollow glass microspheres is 3-100 μm, preferably 3-50 μm, and the active metal used includes metal aluminum, metal magnesium, met...

Embodiment 1

[0038] Preparation and performance testing of hollow porous micron-sized silicon spheres:

[0039] (1) Metal thermal reduction

[0040] Weigh 0.7 grams of lithium powder and 2.0 grams of hollow glass microspheres (particle size 3 microns), grind them evenly in an agate mortar in an argon glove box, transfer them to an alumina crucible, and then transfer them to a tube furnace, argon Heat up to 500°C under air protection and keep warm for 0.5 hour to get composite powder.

[0041] (2) Acid corrosion to remove oxides

[0042] Add the composite powder material obtained in step (1) into 20 mL of pure acetic acid, stir for 2 hours, filter, wash with water, and dry to obtain hollow porous micron-sized silicon spheres.

[0043] (3) Capacity test

[0044] The obtained hollow porous micron-sized silicon sphere material was mixed with conductive agent acetylene black and binder PVDF (polyvinylidene fluoride) according to the mass ratio of 80: 10: 10, and NMP (1-methyl-2-pyrrolidone) ...

Embodiment 2

[0046] Preparation and performance testing of hollow porous micron-sized silicon spheres:

[0047] (1) Metal thermal reduction

[0048] Weigh 0.9 grams of aluminum powder and 1.8 grams of hollow glass microspheres (particle size 10 microns), grind them evenly in an agate mortar, transfer them to an alumina crucible, and then transfer them to a tube furnace, and raise the temperature to 800 °C under the protection of argon. degree, heat preservation for 4 hours to obtain composite powder.

[0049] (2) Acid corrosion to remove oxides

[0050] Add the composite powder material obtained in step (1) into 100 mL of 10% hydrochloric acid solution, stir for 12 hours, filter, wash with water, and dry to obtain hollow porous micron-sized silicon spheres.

[0051] (3) Capacity test

[0052] The obtained hollow porous micron-sized silicon sphere material was mixed with conductive agent acetylene black and binder PVDF (polyvinylidene fluoride) according to the mass ratio of 80: 10: 10, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com