Method for preparing silicon-containing micron-fiber-toughened PHBV composite material

A technology of micro-fiber and composite material, which is applied in the field of preparation of silicon-containing micro-fiber toughened PHBV composite material, can solve the problems of large chemical agents, power, consumption, etc., achieve uniform distribution, overcome flocculation phenomenon, and have a wide range of effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

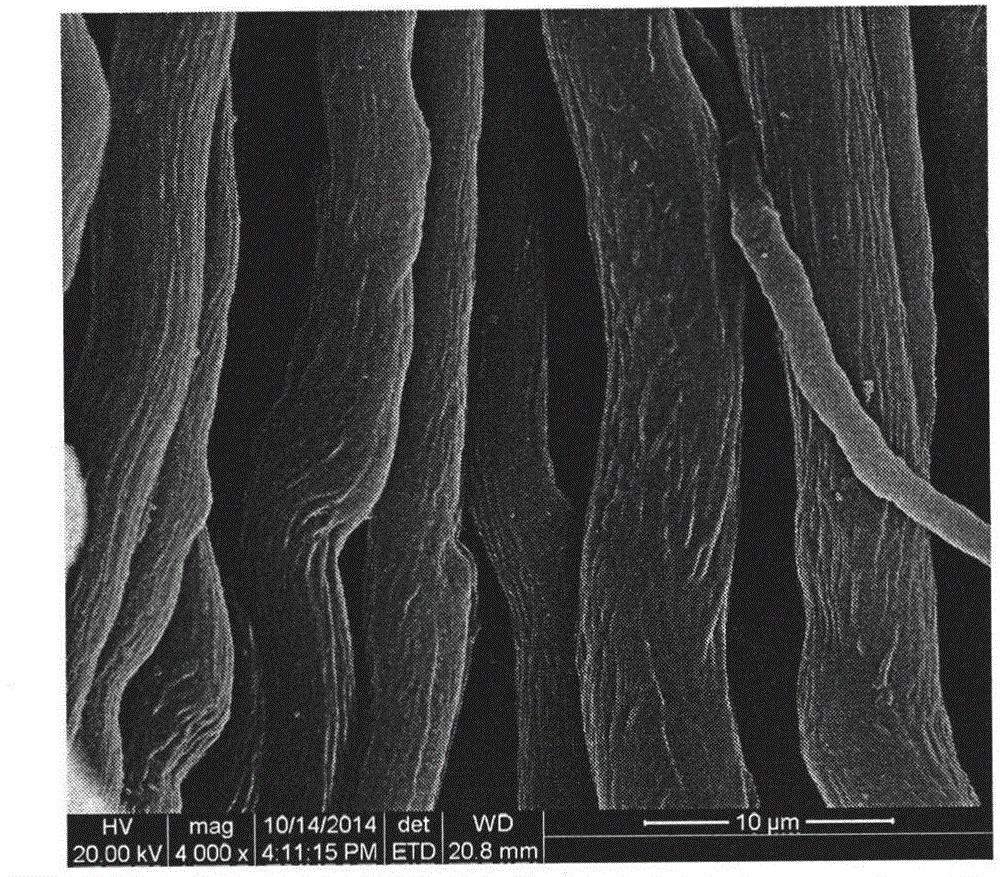

Image

Examples

Embodiment 1

[0014] Example 1, disperse 1g of silicon-containing fiber raw material in 10g of aqueous sodium hydroxide solution with a mass fraction of 10%, and keep it at 20°C for 8h to obtain a blend of silicon-containing fiber and aqueous sodium hydroxide solution; After dilution and filtration, 1% polyethylene glycol was added to the obtained precipitate, and then a homogenizer was used for low-pressure crushing, the crushing pressure was 100 bar, and the number of cycles was 15 times to obtain a silicon-containing micron fiber blend, which was separated, Vacuum drying to obtain silicon-containing microfibers. Melt-blending the prepared silicon-containing micron fibers and poly(β-hydroxybutyrate-β-hydroxyvalerate) (PHBV) at a mass ratio of 1:25, the processing temperature was 175°C, and the screw speed was 10r / min, with a blending time of 2.5min, extruded and granulated to make a toughened PHBV composite material containing silicon microfibers. After testing, the tensile elongation a...

Embodiment 2

[0015] Example 2, disperse 2g of silicon-containing fiber raw material in 40g of aqueous sodium hydroxide solution with a mass fraction of 35%, and keep it at 30°C for 6h to obtain a blend of silicon-containing fiber and aqueous sodium hydroxide solution; the above blend After dilution and filtration, 3% polyethylene glycol was added to the obtained precipitate, and then a homogenizer was used for low-pressure crushing, the crushing pressure was 150 bar, and the number of cycles was 10 times to obtain a silicon-containing micron fiber blend. After separation, vacuum Dry to obtain silicon-containing microfibers. Melt-blending the prepared silicon-containing micron fibers and poly(β-hydroxybutyrate-β-hydroxyvalerate) (PHBV) at a mass ratio of 1:15, the processing temperature was 185°C, and the screw speed was 15r / min, with a blending time of 3.5min, extruded and granulated to make a toughened PHBV composite material containing silicon microfibers. After testing, the tensile el...

Embodiment 3

[0016] Example 3, disperse 2g of silicon-containing fiber raw material in 25g of 20% aqueous sodium hydroxide solution by mass fraction, and keep it at 30°C for 6h to obtain a blend of silicon-containing fiber and aqueous sodium hydroxide solution; the above blend After dilution and filtration, 5% polyethylene glycol was added to the obtained precipitate, and then a homogenizer was used for low-pressure crushing, the crushing pressure was 200 bar, and the number of cycles was 6 times to obtain a silicon-containing micron fiber blend, which was separated, Vacuum drying to obtain silicon-containing microfibers. Melt-blending the obtained silicon-containing micron fibers and poly(β-hydroxybutyrate-β-hydroxyvalerate) (PHBV) at a mass ratio of 1:10, the processing temperature is 185°C, and the screw speed is 20r / min, with a blending time of 5 minutes, extruded and granulated to make a toughened PHBV composite material containing silicon microfibers. After testing, the tensile elo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com